Metals Processing

Metals processing industries employ large, critical assets, the reliability of which is absolutely essential to their business model. An undetected failure of a piece of processing...

行业概览

Metals processing industries employ large, critical assets, the reliability of which is absolutely essential to their business model. An undetected failure of a piece of processing equipment such as a rolling mill gearbox, or a 1000 ton extruder press not only involves the cost of equipment repair and line downtime, but the product quality may be severely impacted. Today more than ever, there is also less redundancy. Oil analysis is a critical aspect of a reliability based maintenance program, and for many large slow speed systems, it is the first line of protection. Spectro’s oil analysis solutions are designed to monitor this critical oil lubricated machinery, and provide the asset owners with timely information for reliability decision support.\r\n\r\n

主要特点

Metals processing industries employ large, critical assets, the reliability of which is absolutely essential to their business model. An undetected failure of a piece of processing equipment such as a rolling mill gearbox, or a 1000 ton extruder press not only involves the cost of equipment repair and line downtime, but the product quality may be severely impacted. Today more than ever, there is also less redundancy. Oil analysis is a critical aspect of a reliability based maintenance program, and for many large slow speed systems, it is the first line of protection. Spectro’s oil analysis solutions are designed to monitor this critical oil lubricated machinery, and provide the asset owners with timely information for reliability decision support.

Challenges

One of the biggest challenges to metal processors is the harsh environment in which they operate. Metals processing plants have tremendous amounts of dust and debris in the air which gets into lubricating oil. Instituting best practices for handling and storage of lubricants can greatly improve reliability.

Another challenge is smaller workforces. Oftentimes as people retire, they are not being replaced, so the workforces are smaller. This means more operators have to understand and be able to perform lubrication analysis. Having oil analysis equipment that is portable, intuitive and easy to use is imperative. It is also important that such equipment provides clear actions as a result of analysis, such as alerting personnel when alarm limits are exceeded or trending analysis indicates an impending problem.

Challenges

One of the biggest challenges to metal processors is the harsh environment in which they operate. Metals processing plants have tremendous amounts of dust and debris in the air which gets into lubricating oil. Instituting best practices for handling and storage of lubricants can greatly improve reliability.

Another challenge is smaller workforces. Oftentimes as people retire, they are not being replaced, so the workforces are smaller. This means more operators have to understand and be able to perform lubrication analysis. Having oil analysis equipment that is portable, intuitive and easy to use is imperative. It is also important that such equipment provides clear actions as a result of analysis, such as alerting personnel when alarm limits are exceeded or trending analysis indicates an impending problem.

典型测试与应用

Contamination of oil is big problem. Contamination can come in the form of debris and wear particles, but water can also be a critical contaminant. The cost of downtime is extremely high in metals processing plants. Therefore quick turnaround of test results is essential to keeping a plant up and running.

Wear

Particle count- a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Contamination

Water- Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

Wear

Particle count- a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Contamination

Water- Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

行业资源

支持产品

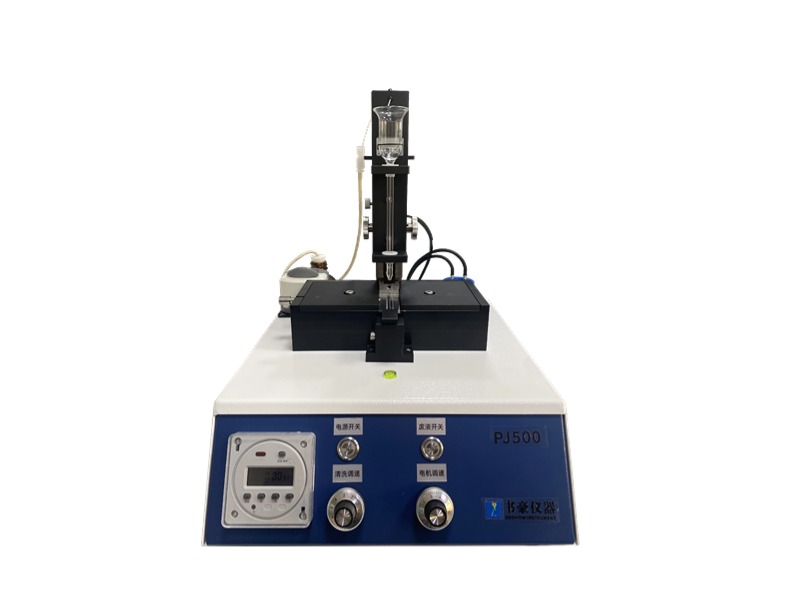

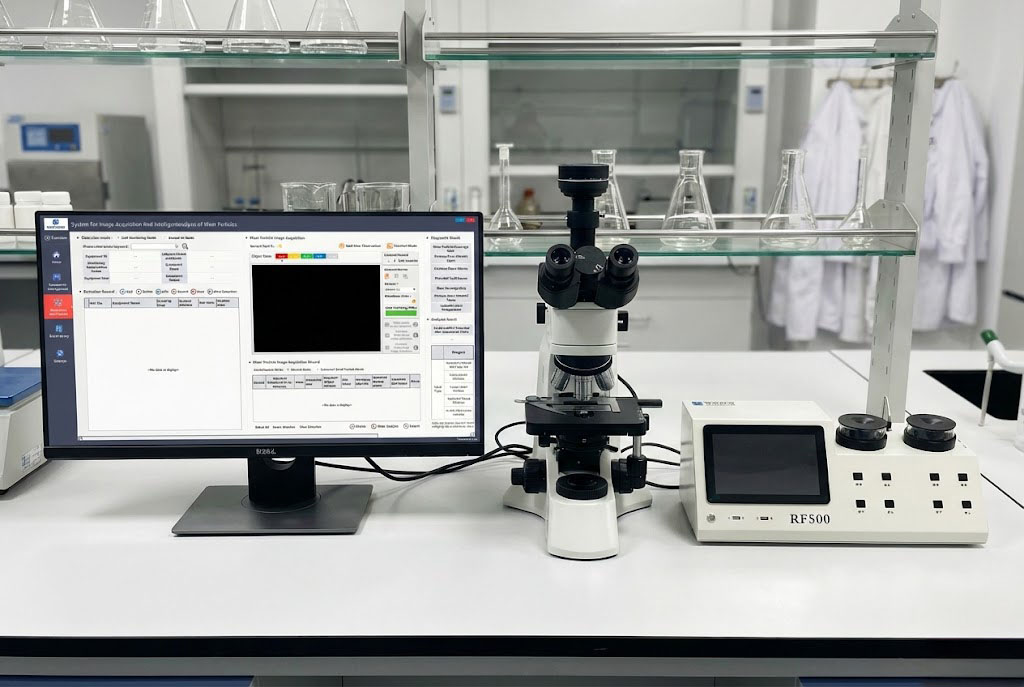

Oil Analysis

Oil Analysis

准备找到正确的解决方案?

我们的团队可以帮助您为您的应用选择完美的产品 Metals Processing 应用