Main

تحليل الزيت

تحليل جسيمات التآكل

فيروغراف تحليل مزدوج PA100

رقم القطعة:

PA100

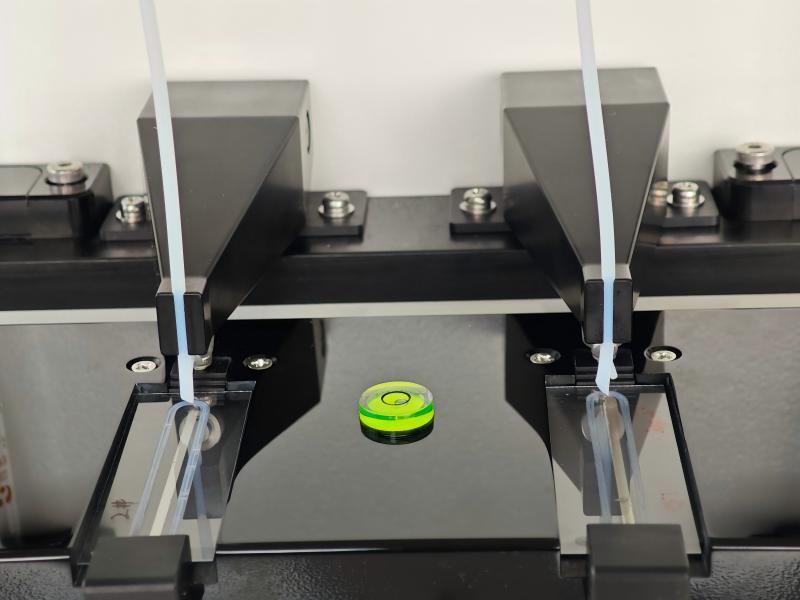

PA100 هو جهاز فيروغرافي مكتبي متقدم مصمم للتحليل النوعي والكمي لجسيمات التآكل في زيوت التشحيم والسوائل. يتميز بقدرة تحليل مزدوجة—يجمع بين الفيروغرافيا المستمرة الكلاسيكية للفحص البصري والقياس المباشر للقراءة للتكميم الآلي. يوفر هذا النهج الهجين رؤية شاملة لحالات التآكل: الفحص البصري لشكل التآكل بالإضافة إلى البيانات الرقمية للتوجهات والتشخيص في برامج الصيانة التنبؤية.

قدرة الوضع المزدوج

يجمع بين الفيروجرافيا المستمرة (شرائح للفحص المجهري) والقياس المباشر، مما يعطي نظرة بصرية ورقمية لجسيمات التآكل.

عملية مؤتمتة بالكامل

حقن العينة الآلي، وتوليد الشرائح، والتحليل ثنائي الوضع، وإخراج النتائج الرقمية يبسط المسار من العينة إلى التقييم.

اكتساب بيانات جاهز للاتجاهات

يشتمل النظام على برنامج لتتبع تركيز جسيمات التآكل بمرور الوقت، مما يساعد في الكشف المبكر عن الأعطال وتخطيط دورة الحياة.

تقنية مغناطيسية عالية الحساسية

يستخدم مجالات مغناطيسية قوية لعزل الجسيمات الحديدية، وفصلها حسب الحجم والحجم المغناطيسي للاستشعار الدقيق.

الحد الأدنى من حجم العينة

يتطلب فقط 1-2 مل من الزيت، وإنتاجية سريعة عادةً أقل من 15 دقيقة، مثالي للاستخدام في المختبر أو ورشة العمل.

واجهة سهلة الاستخدام

تحكم بشاشة تعمل باللمس مع تخزين البيانات، والتصدير عبر USB/Ethernet، وبرمجيات مدمجة للاتجاهات لتسهيل التحليل.

| المواصفة | القيمة |

|---|---|

| حجم العينة | 1–2 مل زيت |

| زمن التحليل | ≤15 دقيقة (وضع مزدوج) |

| كشف الجسيمات | نوعي (مجهري) + كمي (حساسات قراءة مباشرة) |

| شدة المجال المغناطيسي | تدرج عالي (~1.5 تسلا) |

| واجهة البيانات | يو إس بي + إيثرنت |

| واجهة العرض | شاشة LCD تعمل باللمس |

| البرمجيات | تحكم مزدوج الوضع + تحليل الاتجاهات |

| المذيب | رباعي كلورو الإيثيلين (لتحضير الشرائح) |