Metals Processing

Industry Overview

Key Features

Challenges

One of the biggest challenges to metal processors is the harsh environment in which they operate. Metals processing plants have tremendous amounts of dust and debris in the air which gets into lubricating oil. Instituting best practices for handling and storage of lubricants can greatly improve reliability.

Another challenge is smaller workforces. Oftentimes as people retire, they are not being replaced, so the workforces are smaller. This means more operators have to understand and be able to perform lubrication analysis. Having oil analysis equipment that is portable, intuitive and easy to use is imperative. It is also important that such equipment provides clear actions as a result of analysis, such as alerting personnel when alarm limits are exceeded or trending analysis indicates an impending problem.

Typical Tests & Applications

Wear

Particle count- a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Contamination

Water- Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

Industry Resources

No Resources Available

We're currently updating our resource library for this industry. Check back soon or contact us to request specific documentation.

Request DocumentationSupporting Products

Oil Analysis

Oil Analysis

Dual analysis ferrograph PA100

The PA100 is an advanced bench-top ferrograph designed for both qualitative and quantitative wear pa...

Oil Analysis

Oil Analysis

Dual analysis ferrograph PA300

The PA300 is a dual-mode bench-top ferrograph designed for comprehensive wear particle evaluation in...

Metal Analysis

Metal Analysis

E3 Esaport

The E3 Esaport is a compact, field-ready spark/arc optical emission spectrometer (OES) designed for ...

Metal Analysis

Metal Analysis

E4 Esaport Plus

The Esaport Plus is GNR’s latest-generation mobile spark optical emission spectrometer, marking ...

Metal Analysis

Metal Analysis

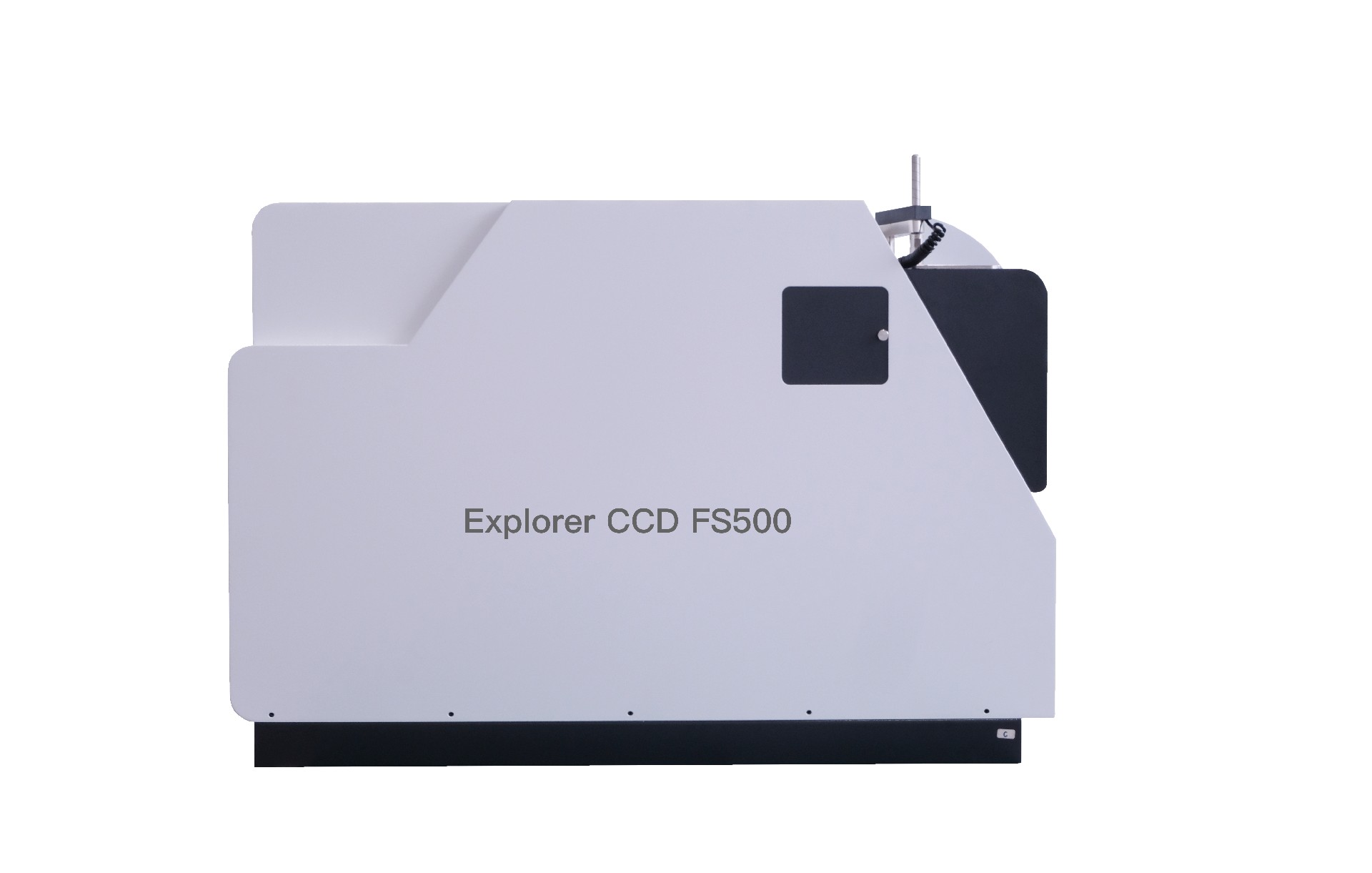

Explorer CCD FS500

The FS500 is a state-of-the-art full-spectrum spark optical emission spectrometer designed for rapid...

Metal Analysis

Metal Analysis

Explorer CCD FS800

The FS800 is an advanced desktop spark optical emission spectrometer that utilizes a high-resolution...

Oil Analysis

Oil Analysis

FDM 6000 Series

The FDM 6000 is a rugged, battery-powered instrument designed for rapid, on-site measurement of fuel...

Oil Analysis

Oil Analysis

FluidScan® 1000 Series

The FluidScan is a handheld infrared spectrometer used for on-site oil condition analysis. It measur...

Metal Analysis

Metal Analysis

Fluorescence spectrometer AU8000

The AU8000 is a bench-top X-ray fluorescence (XRF) analyzer optimized for rapid, non-destructive det...

Metal Analysis

Metal Analysis

Glow spectrometer GDS8000

The GDS8000 is a high-performance glow discharge optical emission spectrometer designed for fast dep...

Metal Analysis

Metal Analysis

Hollow cathode spectrometer HCD1000

The HCD1000 is a high-precision optical emission spectrometer using a hollow-cathode discharge sourc...

Oil Analysis

Oil Analysis

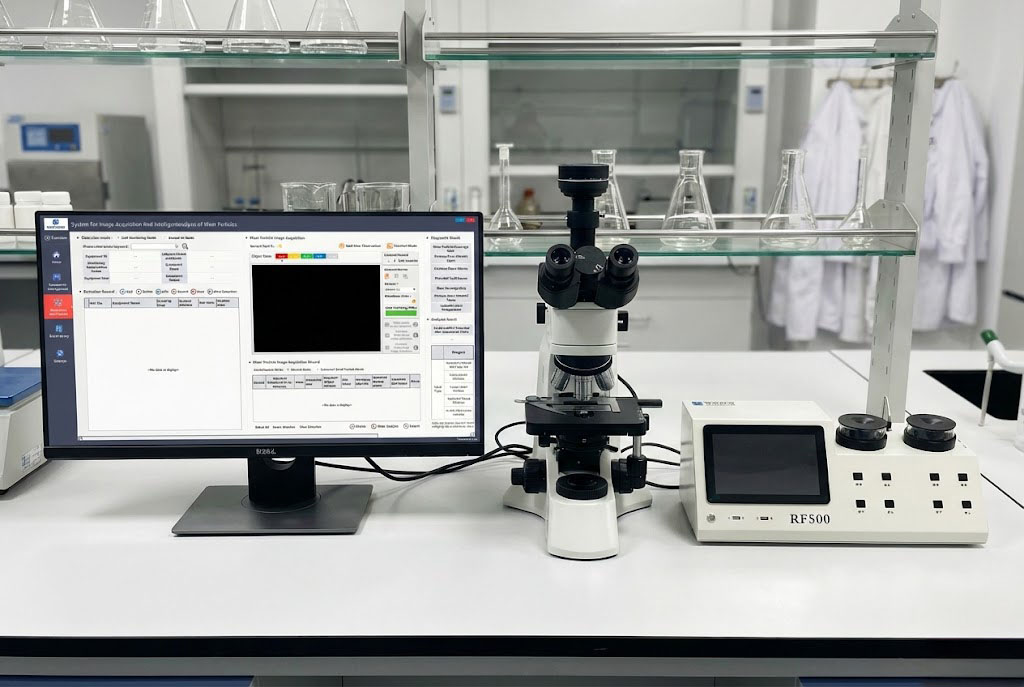

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

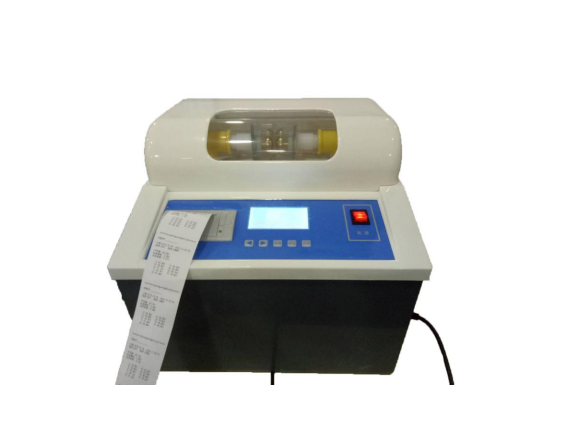

JKJQ‑1A Insulating Oil Dielectric Strength Tester

The JKJQ‑1A is a fully automatic, portable single-cup tester designed to measure the dielectric (b...

Oil Analysis

Oil Analysis

JKJQ‑1B Dielectric Strength Tester

The JKJQ‑1B is a fully automatic, single-cup dielectric strength tester for insulating oils, ideal...

Oil Analysis

Oil Analysis

MiniVisc 3000

The MiniVisc 3000 is a groundbreaking portable kinematic viscometer that delivers laboratory-grade v...

Oil Analysis

Oil Analysis

Pi Raptor Portable

The Raptor Portable Dry Powder Particle Size & Shape Analyzer is the first truly portable system tha...

Oil Analysis

Oil Analysis

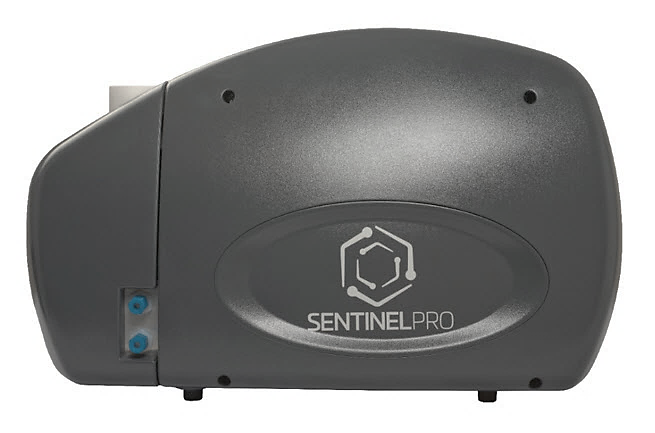

Pi Sentinel PRO

The SentinelPro is a high-performance dynamic image analyzer designed for applications where particl...

Oil Analysis

Oil Analysis

Portable Kinematic Viscometer VS800

The VS800 Portable Kinematic Viscometer is a precision, multi-purpose viscosity measurement tool des...

Oil Analysis

Oil Analysis

Portable oil particle counter SLPC300

The SLPC300 is a portable oil particle counter that utilizes the light-blocking principle to measure...

Oil Analysis

Oil Analysis

R4 RotrOil (Automatic Sample Changer)

The R4 RotrOil is an advanced, fully automated version of GNR's RotrOil elemental spectrometer. It i...

Metal Analysis

Metal Analysis

S1 MiniLab 150

The MiniLab 150 is an ultra-compact optical emission spectrometer that combines advanced spark-based...

Metal Analysis

Metal Analysis

S3 MiniLab 300

The MiniLab 300 is an ultra-compact, high-performance desktop spark optical emission spectrometer (O...

Metal Analysis

Metal Analysis

S5 Solaris Plus

The S5 Solaris Plus is a high-performance desktop optical emission spectrometer (OES) engineered for...

Metal Analysis

Metal Analysis

S6 Sirius 500

The Sirius 500 is a cutting-edge laboratory-grade optical emission spectrometer (OES) featuring a hi...

Metal Analysis

Metal Analysis

S7 Metal Lab Plus

The S7 Metal Lab Plus is a powerful, compact Desktop Optical Emission Spectrometer designed for high...

Metal Analysis

Metal Analysis

S9 Atlantis

The S9 Atlantis is GNR’s top-of-the-line laboratory optical emission spectrometer, combining decad...

Oil Analysis

Oil Analysis

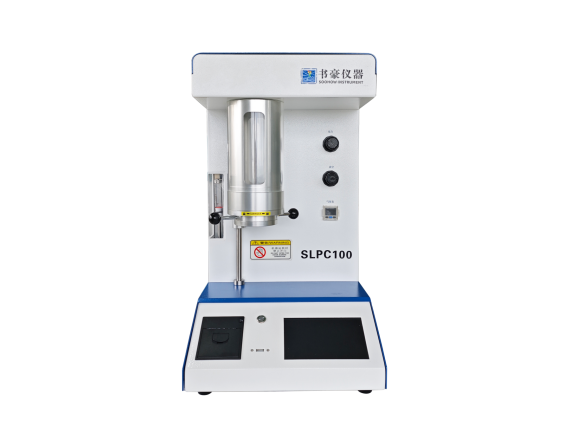

SLPC100 Desktop Oil Particle Counter

The SLPC100 is a desktop oil particle counter that employs the internationally recognized light obsc...

Metal Analysis

Metal Analysis

Spark direct reading spectrometer AES998

The AES998 is a high-performance desktop Optical Emission Spectrometer (OES) engineered for fast, ac...

Oil Analysis

Oil Analysis

SpectrOil 100 Series

The SpectrOil 100 Series is a high-precision elemental analyzer based on Rotating Disc Electrode Opt...

Oil Analysis

Oil Analysis

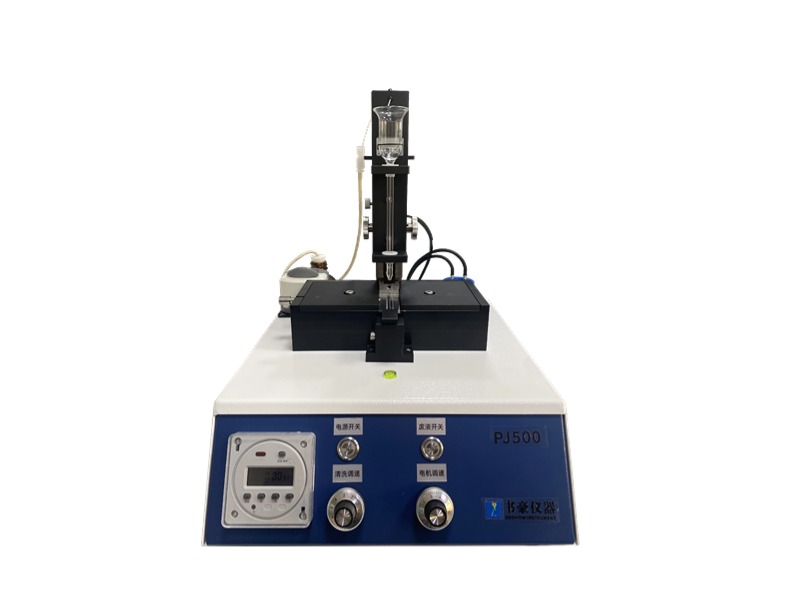

Thistle tube ferrospectrometer PJ500

The PJ500 is a portable, thistle‑tube based ferrographic analyzer designed to separate and evaluat...

Oil Analysis

Oil Analysis

VS600 Portable Rapid Motion Viscometer

The VS600 Portable Rapid Motion Viscometer is a high-efficiency field instrument designed for fast a...

Metal Analysis

Metal Analysis

X-MAX II handheld X-ray fluorescence spectrometer

The X‑MAX II is Soohow’s latest-generation handheld XRF, featuring over 12 years of R&D expert...

Ready to Find the Right Solution?

Our team can help you select the perfect products for your Metals Processing applications