Main

Analisis Oli

Penghitung partikel

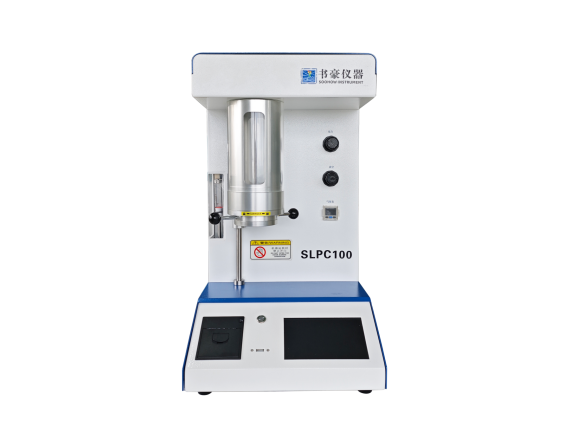

Penghitung Partikel Oli Portabel SLPC300

Nomor Bagian:

SLPC300

SLPC300 adalah penghitung partikel oli portabel yang menggunakan prinsip pemblokiran cahaya untuk mengukur partikel padat dalam berbagai cairan. Alat ini mendukung mode operasi offline dan online.

Mode Operasi Ganda – Offline & Online

SLPC300 menawarkan keserbagunaan yang tak tertandingi dengan kemampuannya untuk beroperasi dalam mode offline dan online. Dalam mode offline, sampel dapat diambil secara manual dari sistem apa pun dan diuji dengan persiapan minimal. Dalam mode online, perangkat dapat langsung dihubungkan ke sistem bertekanan (hingga 40 MPa opsional), yang memungkinkan pemantauan kebersihan cairan secara terus-menerus dalam waktu nyata. Fungsionalitas ganda ini menjadikannya ideal untuk digunakan di laboratorium, departemen pemeliharaan, dan operasi layanan lapangan.

Bersertifikat Standar Internasional

SLPC300 dikalibrasi pabrik dan diverifikasi menurut standar ISO 4402, ISO 11171, dan GB/T 18854, memastikan akurasi tinggi, reproduktifitas, dan konsistensi dalam deteksi dan penghitungan ukuran partikel. Ini ideal untuk perusahaan yang memerlukan kepatuhan terhadap standar pemantauan kebersihan internasional dalam sistem hidrolik dan pelumasan.

Pelaporan Kebersihan Multi-Standar

Perangkat ini mendukung pelaporan bawaan menurut berbagai standar kebersihan global, termasuk ISO 4406 (1999/2007/1987), NAS 1638, AS 4059E/F, GJB420A, dan lainnya. Pengguna dapat memilih standar mana yang akan dilaporkan, dan bahkan menambahkan ambang batas khusus untuk aplikasi tertentu.

Sensitivitas Tinggi dengan 32 Saluran Deteksi

Dilengkapi dengan 32 saluran deteksi optik dan resolusi 0,1 µm, SLPC300 mendeteksi partikel sekecil 1 µm (ISO 4402) atau 4 µm (ISO 11171). Hal ini membuatnya cocok untuk memantau sistem ultra-bersih, termasuk hidrolik penerbangan, mesin presisi, dan unit daya kritis.

Pengambilan Sampel Cepat & Pembersihan Efisien

Berkat laju aliran variabel 5–60 mL/menit, pengguna dapat menyelesaikan pengambilan sampel dan pembersihan internal otomatis dengan cepat, meningkatkan produktivitas selama analisis multi-sampel. Sistem ini dapat menangani cairan viskositas rendah dan tinggi dengan mudah, mempertahankan aliran yang stabil dan pembacaan yang akurat.

Baterai Lithium Bawaan untuk Portabilitas

Dirancang untuk mobilitas sejati, SLPC300 dilengkapi dengan baterai lithium internal yang dapat diisi ulang, memungkinkannya digunakan di lokasi terpencil atau pada peralatan tanpa daya eksternal. Alat ini juga mendukung input AC (110–240 V), membuatnya dapat beradaptasi dengan lingkungan lapangan dan laboratorium.

Antarmuka Ramah Pengguna & Ekspor Data

Perangkat ini menyertakan layar sentuh atau antarmuka tampilan sederhana (tergantung model) dengan navigasi menu yang intuitif. Ini memungkinkan pengguna untuk melihat hasil waktu nyata, menyimpannya, dan mengekspor data melalui USB untuk analisis atau pengarsipan lebih lanjut.

| Spesifikasi | Nilai |

|---|---|

| Prinsip Deteksi | Pemblokiran cahaya (oklusi optik) |

| Mode Operasi | Offline, online (in-line dengan tekanan hingga opsional 40 MPa) |

| Rentang Ukuran Partikel | 1–500 µm |

| Sensitivitas | 1 µm (ISO 4402) atau 4 µm (GB/T 18854, ISO 11171) |

| Saluran Deteksi | 32 saluran dengan interval 0,1 µm |

| Volume Sampel | 10–100 mL |

| Laju Aliran Pengambilan Sampel | 5–60 mL/min (default 25 mL/min) |

| Laju Aliran Pembersihan | 5–60 mL/min |

| Rentang Jumlah Partikel | Batas kesalahan tumpang tindih: 12.000–40.000 partikel/mL |

| Akurasi Penghitungan | Kesalahan relatif ±10%, repetabilitas RSD <2% |

| Rentang Suhu Pengujian | 0°C–80°C (cairan); –20°C–60°C (operasi); –30°C–80°C (penyimpanan) |

| Pasokan Daya / Catu Daya | 110–240 V AC, baterai lithium bawaan |

| Standar yang Didukung | ISO 4402, ISO 11171, GB/T 18854, NAS 1638, AS4059E/F, GJB420, dll. |