Racing

Industry Overview

Key Features

Not only do the racing teams themselves take Spectro Scientific instruments to races, but the companies that design, build and test racing engines also are Spectro Scientific customers. We welcome the opportunity to continue to be of service to existing customers and to assist new customers with their oil analysis instrumentation requirements.

Challenges

The biggest concern for race teams is wear debris that can damage the engine. Being able to identify the debris tells them where the particles are coming from. Most of the top teams use Optical Emission Spectrometers to analyze up to 32 metals found in the oil. Knowing what metals are present and in what concentration allows them to trend things like engine wear and oil breakdown.

Oil viscosity is also a critical component for a high speed engine. Any breakdown in viscosity could cause an engine to fail.

Typical Tests & Applications

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Chemistry

Total Base Number (TBN) - TBN measures the amount of active additive left in a sample of oil. The TBN is useful for people who want to extend their oil usage far beyond the normal range. The TBN of a used oil can aid the user in determining how much reserve additive the oil has left to neutralize acids. The lower the TBN reading, the less active additive the oil has left.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Oxidation, Nitration, Sulfation - Lubricating oil at elevated temperatures can react with oxygen and nitrogen in the atmosphere, as well as sulfur in fuel, to form undesirable by-products that can affect the oil's viscosity and lead to corrosion or damage of equipment.

Contamination

Glycol - Glycol is found in engine coolant. If glycol is found in engine oil it typically indicates there is a leak in the engine that allows coolant into the oil system. Glycol reduces the oil's protective properties and can cause catastrophic damage to the engine components.

Industry Resources

No Resources Available

We're currently updating our resource library for this industry. Check back soon or contact us to request specific documentation.

Request DocumentationSupporting Products

Oil Analysis

Oil Analysis

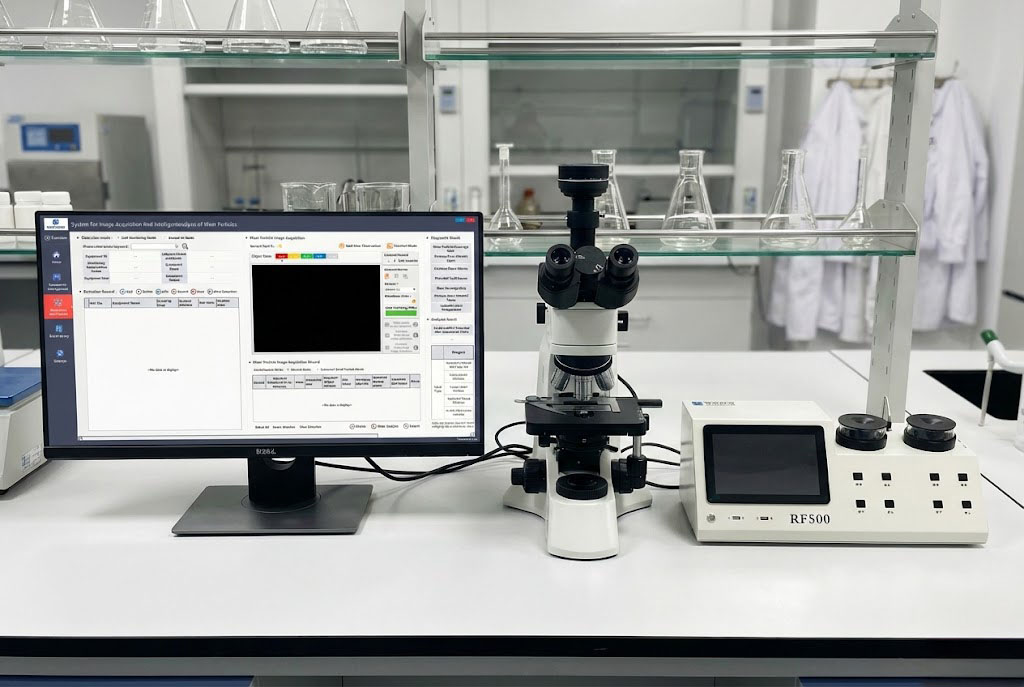

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

LaserNet 200 Series

The LaserNet 200 Series is an advanced, automated particle analysis system designed to detect, class...

Oil Analysis

Oil Analysis

MiniVisc 3000

The MiniVisc 3000 is a groundbreaking portable kinematic viscometer that delivers laboratory-grade v...

Oil Analysis

Oil Analysis

Portable Kinematic Viscometer VS800

The VS800 Portable Kinematic Viscometer is a precision, multi-purpose viscosity measurement tool des...

Oil Analysis

Oil Analysis

Portable oil particle counter SLPC300

The SLPC300 is a portable oil particle counter that utilizes the light-blocking principle to measure...

Oil Analysis

Oil Analysis

Positive and Negative Pressure Sampler PC‑VES

The PC‑VES is a portable positive/negative pressure oil sampler designed for high-viscosity fluids...

Oil Analysis

Oil Analysis

RotrOil

The RotrOil is GNR’s latest-generation Rotating Disc Electrode Optical Emission Spectrometer (RDE-...

Oil Analysis

Oil Analysis

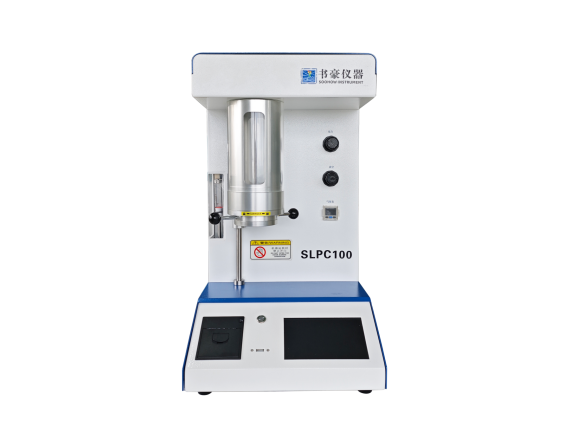

SLPC100 Desktop Oil Particle Counter

The SLPC100 is a desktop oil particle counter that employs the internationally recognized light obsc...

Oil Analysis

Oil Analysis

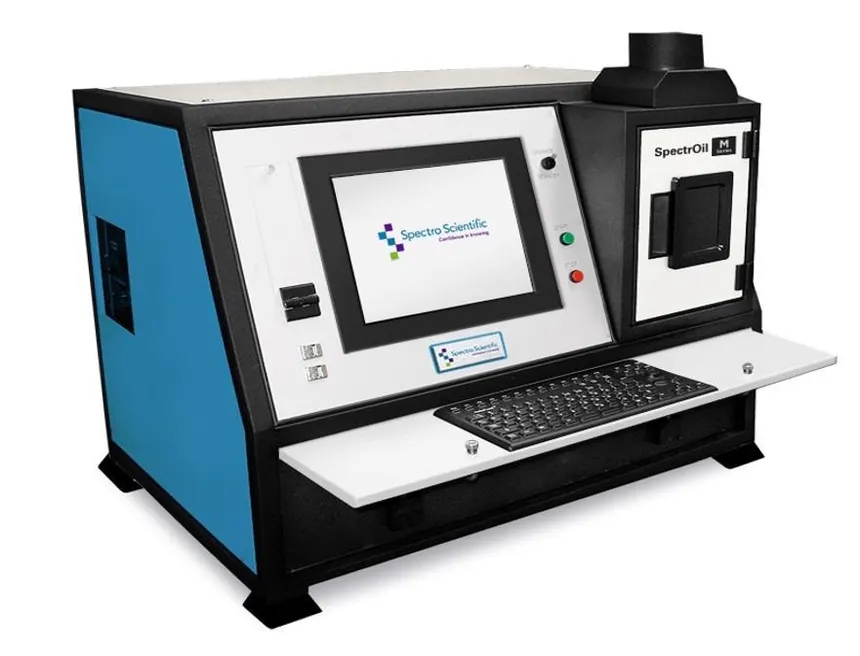

SpectrOil M Series

The SpectrOil M Series is a compact, rugged, and highly reliable Rotating Disc Electrode Optical E...

Oil Analysis

Oil Analysis

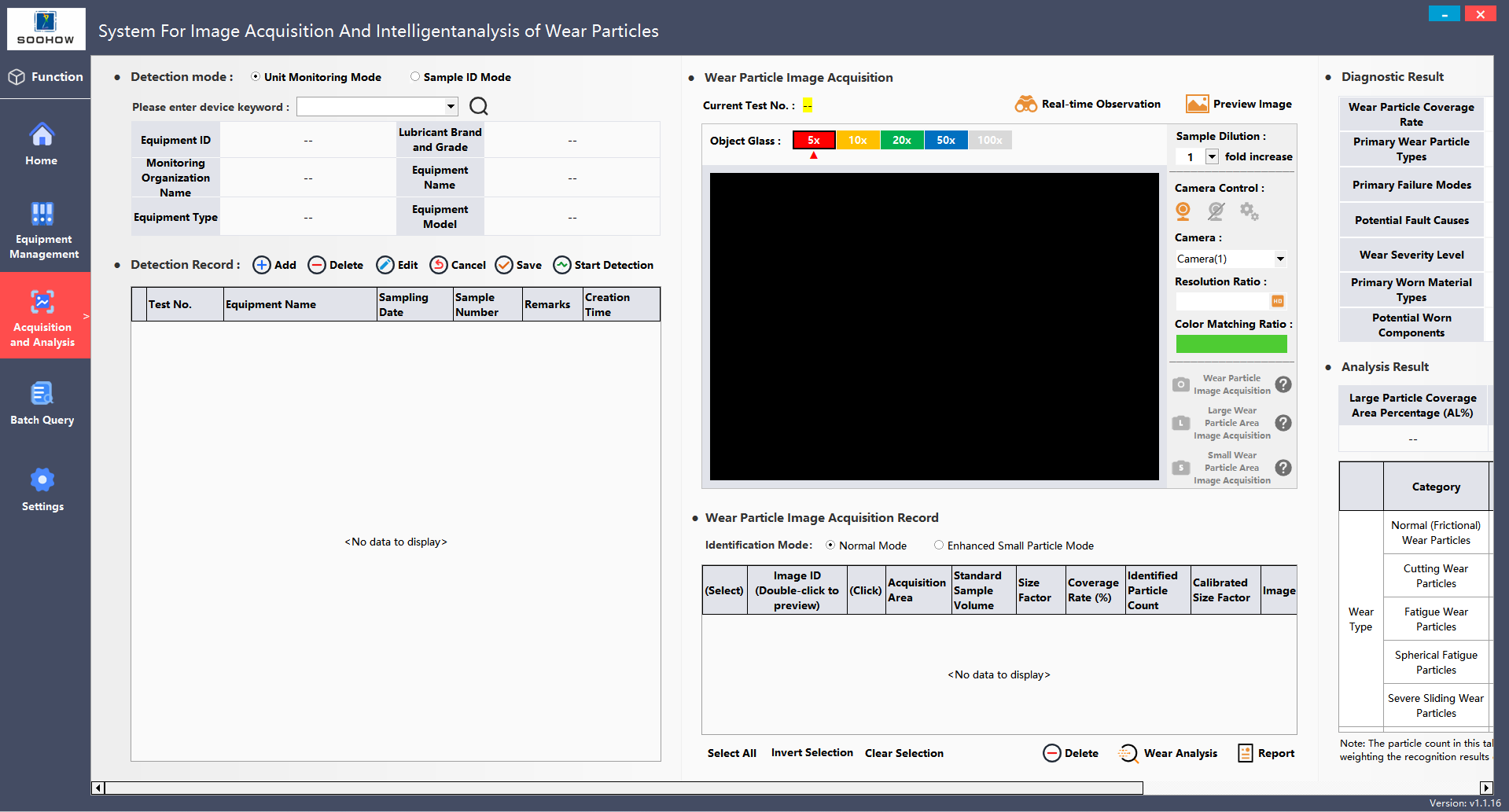

Wear Particle Image Acquisition & Intelligent Analysis System

This advanced system is a cutting-edge solution for modern Ferrography and oil condition monitoring....

Ready to Find the Right Solution?

Our team can help you select the perfect products for your Racing applications