Kereta Api

Ikhtisar Industri

Fitur Utama

Challenges

Oil analysis for predictive monitoring was first used by the US railroad industry to monitor the health of locomotives. In 1946 the Denver and Rio Grande Railroad's research laboratory successfully detected diesel engine problems through wear metal analysis of used oils. The development of the spectrograph to detect individual metallic elements, such as copper and iron, was a key factor in their success. This practice was soon accepted and used extensively throughout the railroad industry.

With such large equipment hauling heavy loads, wear is one of the critical measurements to monitor for predictive maintenance. A sudden increase in wear particles is typically indicative of an impending failure. Knowing the type of wear particles, sliding wear versus fatigue wear (for instance), also helps to determine the source of the particles.

Tes & Aplikasi Khas

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

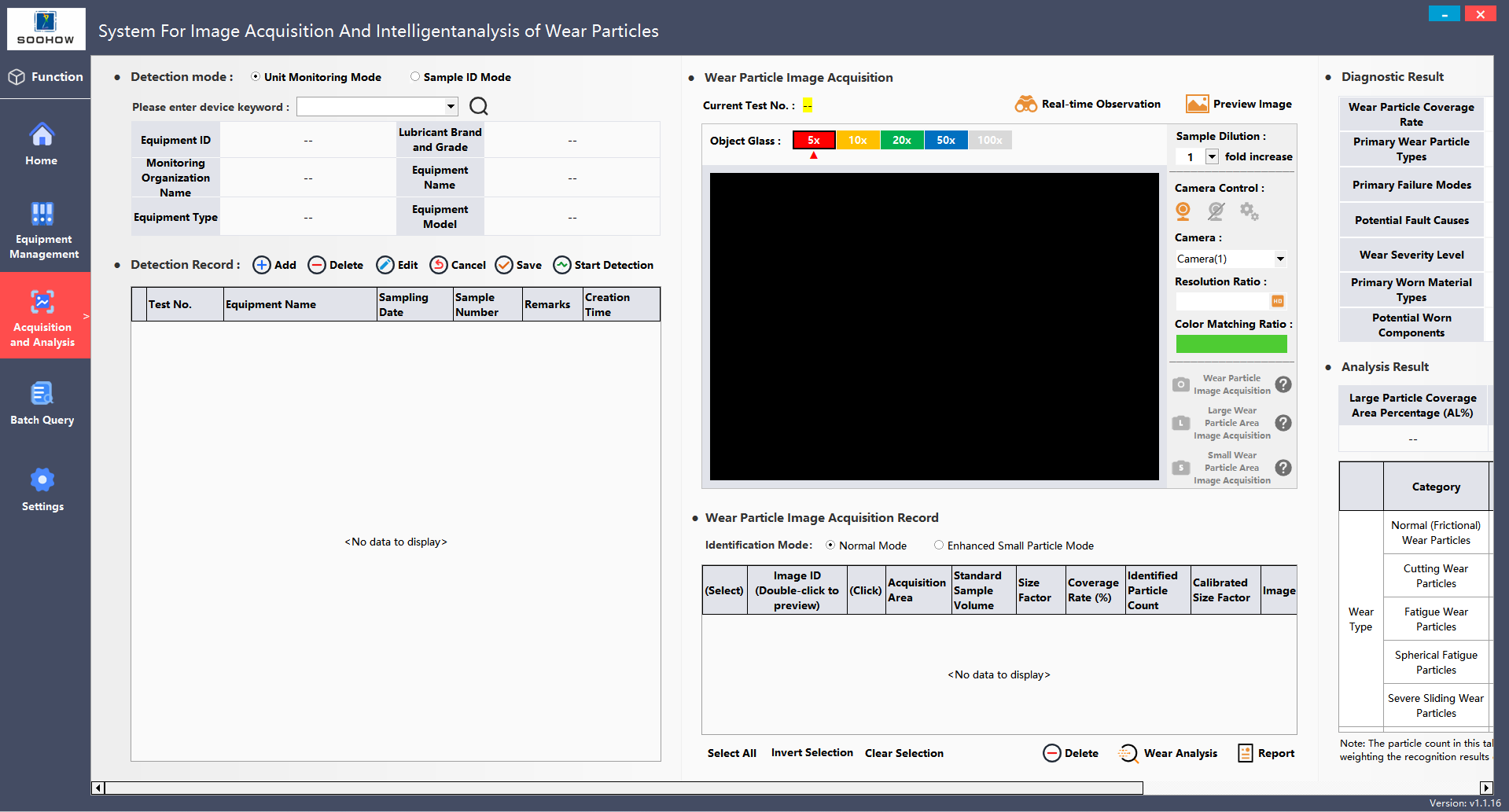

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Sumber Daya Industri

Tidak Ada Sumber Daya Tersedia

Kami sedang memperbarui perpustakaan sumber daya kami untuk industri ini. Periksa kembali segera atau hubungi kami untuk meminta dokumentasi khusus.

Minta DokumentasiProduk Pendukung

Oil Analysis

Oil Analysis

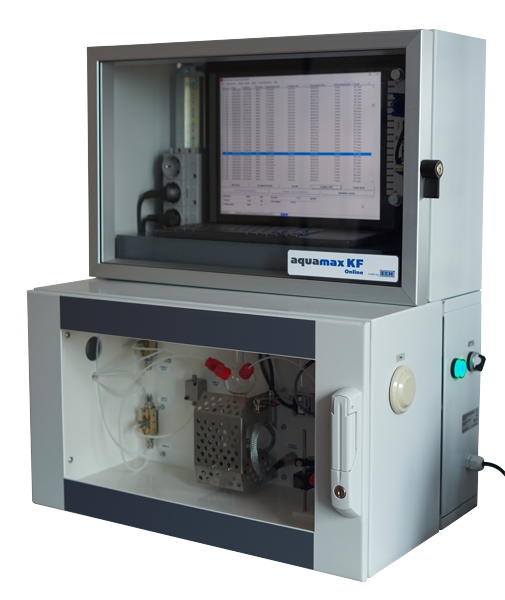

Aquamax KF Online

Aquamax KF Online adalah sistem titrasi Karl Fischer otomatis berkinerja tinggi yang dirancang untuk...

Oil Analysis

Oil Analysis

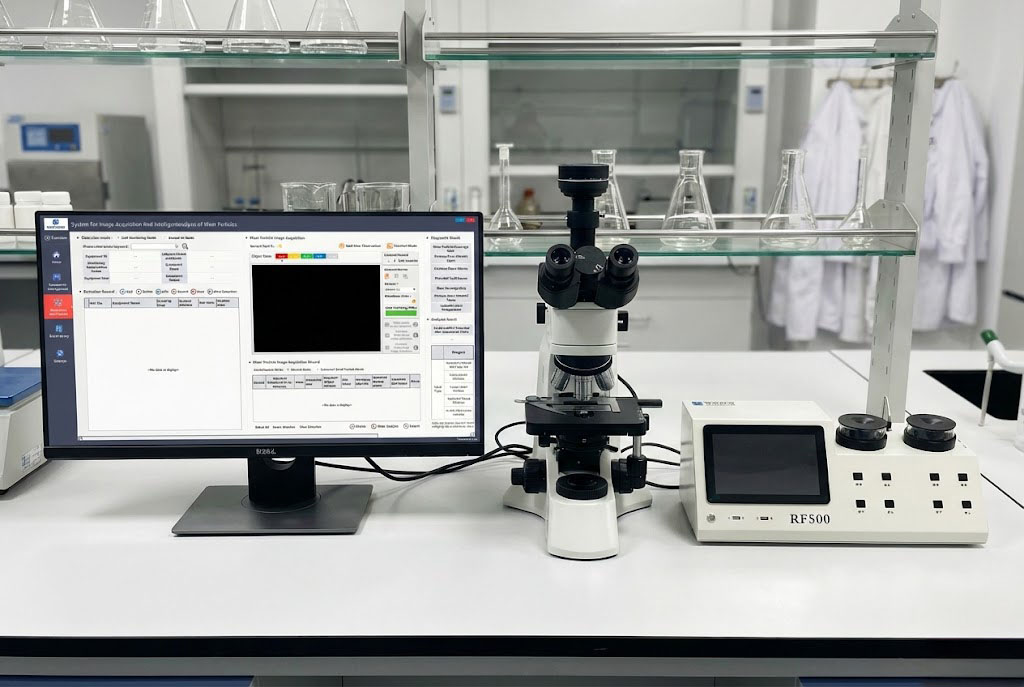

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

Meter Besi PF100

PF100 adalah pengukur besi feromagnetik portabel untuk deteksi cepat partikel aus logam dalam oli da...

Oil Analysis

Oil Analysis

Seri LaserNet 200

LaserNet 200 Series adalah sistem analisis partikel otomatis canggih yang dirancang untuk mendeteksi...

Oil Analysis

Oil Analysis

MiniVisc 3000

MiniVisc 3000 adalah viskometer kinematik portabel inovatif yang memberikan pengukuran viskositas ti...

Oil Analysis

Oil Analysis

Penghitung Partikel Oli Portabel SLPC300

SLPC300 adalah penghitung partikel oli portabel yang menggunakan prinsip pemblokiran cahaya untuk me...

Oil Analysis

Oil Analysis

TruVu™ 360

TruVu 360 adalah platform perangkat lunak diagnostik milik Spectro Scientific yang dirancang untuk m...

Oil Analysis

Oil Analysis

Sistem Akuisisi Gambar & Analisis Cerdas Partikel Keausan Berbasis AI

Sistem canggih ini adalah solusi mutakhir untuk Ferografi modern dan pemantauan kondisi oli. Dengan ...

Siap Menemukan Solusi yang Tepat?

Tim kami dapat membantu Anda memilih produk yang sempurna untuk Kereta Api aplikasi