Railways

Aperçu de l'Industrie

Caractéristiques Clés

Challenges

Oil analysis for predictive monitoring was first used by the US railroad industry to monitor the health of locomotives. In 1946 the Denver and Rio Grande Railroad's research laboratory successfully detected diesel engine problems through wear metal analysis of used oils. The development of the spectrograph to detect individual metallic elements, such as copper and iron, was a key factor in their success. This practice was soon accepted and used extensively throughout the railroad industry.

With such large equipment hauling heavy loads, wear is one of the critical measurements to monitor for predictive maintenance. A sudden increase in wear particles is typically indicative of an impending failure. Knowing the type of wear particles, sliding wear versus fatigue wear (for instance), also helps to determine the source of the particles.

Tests et Applications Typiques

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

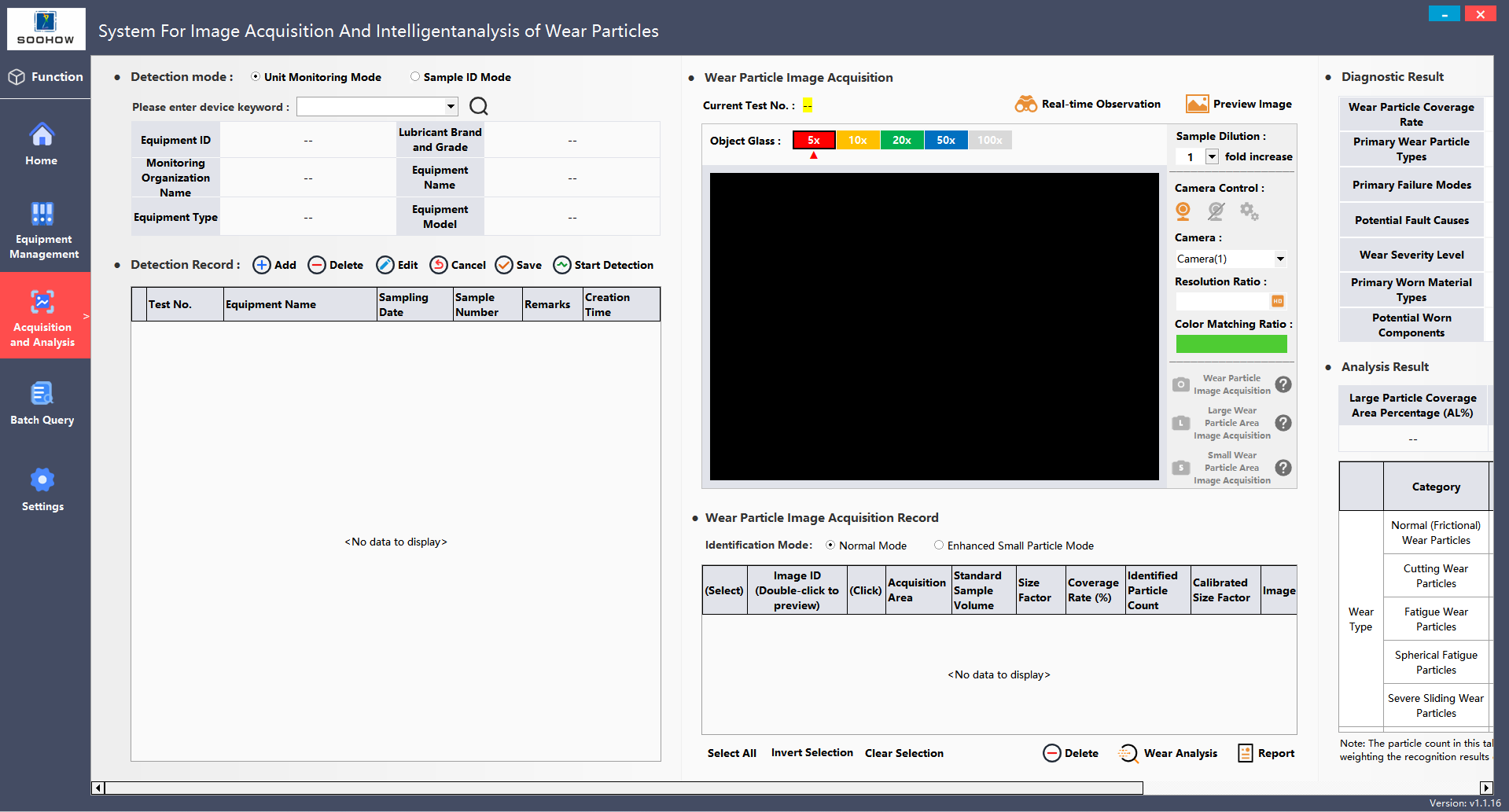

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Ressources de l'Industrie

Pas de Ressources Disponibles

Nous mettons à jour notre bibliothèque de ressources pour cette industrie. Revenez bientôt ou contactez-nous pour demander une documentation spécifique.

Demander une DocumentationProduits de Support

Oil Analysis

Oil Analysis

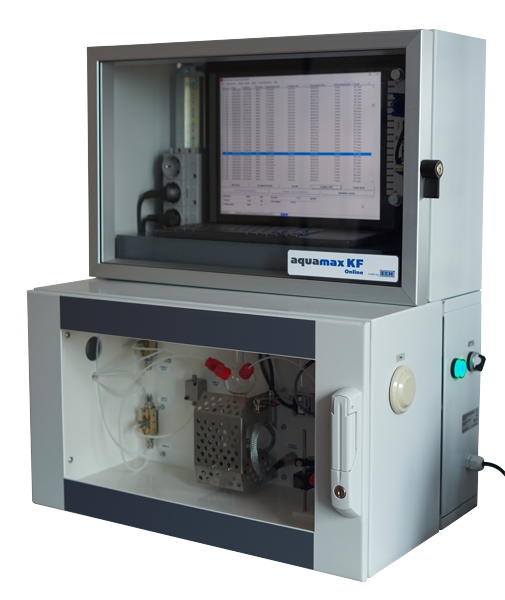

Aquamax KF Online

L’Aquamax KF Online est un système de titrage Karl Fischer automatisé haute performance conçu p...

Oil Analysis

Oil Analysis

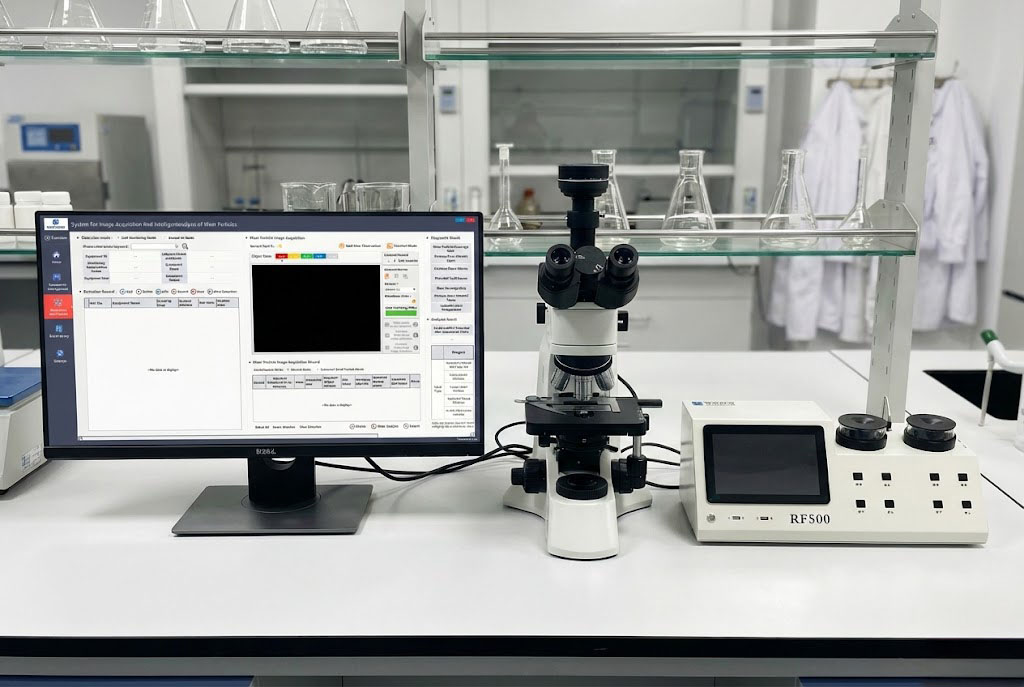

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

Ferromètre PF100

Le PF100 est un ferromètre portable conçu pour la détection rapide et précise des particules d�...

Oil Analysis

Oil Analysis

Série LaserNet 200

La série LaserNet 200 est un système avancé et automatisé d’analyse des particules conçu pour...

Oil Analysis

Oil Analysis

MiniVisc 3000

Le MiniVisc 3000 est un viscosimètre cinématique portable révolutionnaire qui fournit des mesures...

Oil Analysis

Oil Analysis

Compteur de particules d’huile portable SLPC300

Le SLPC300 est un compteur de particules d’huile portable qui utilise le principe de blocage de la...

Oil Analysis

Oil Analysis

TruVu™ 360

TruVu™ 360 est la plateforme logicielle de diagnostic propriétaire de Spectro Scientific conçue ...

Oil Analysis

Oil Analysis

Système d'Acquisition d'Images et d'Analyse Intelligente des Particules d'Usure (Propulsé par l'IA)

Description du Produit Ce système avancé est une solution de pointe pour la ferrographie moderne e...

Prêt à Trouver la Bonne Solution?

Notre équipe peut vous aider à sélectionner les produits parfaits pour vos Railways applications