Railways

نظرة عامة على الصناعة

الميزات الرئيسية

Challenges

Oil analysis for predictive monitoring was first used by the US railroad industry to monitor the health of locomotives. In 1946 the Denver and Rio Grande Railroad's research laboratory successfully detected diesel engine problems through wear metal analysis of used oils. The development of the spectrograph to detect individual metallic elements, such as copper and iron, was a key factor in their success. This practice was soon accepted and used extensively throughout the railroad industry.

With such large equipment hauling heavy loads, wear is one of the critical measurements to monitor for predictive maintenance. A sudden increase in wear particles is typically indicative of an impending failure. Knowing the type of wear particles, sliding wear versus fatigue wear (for instance), also helps to determine the source of the particles.

الاختبارات والتطبيقات النموذجية

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

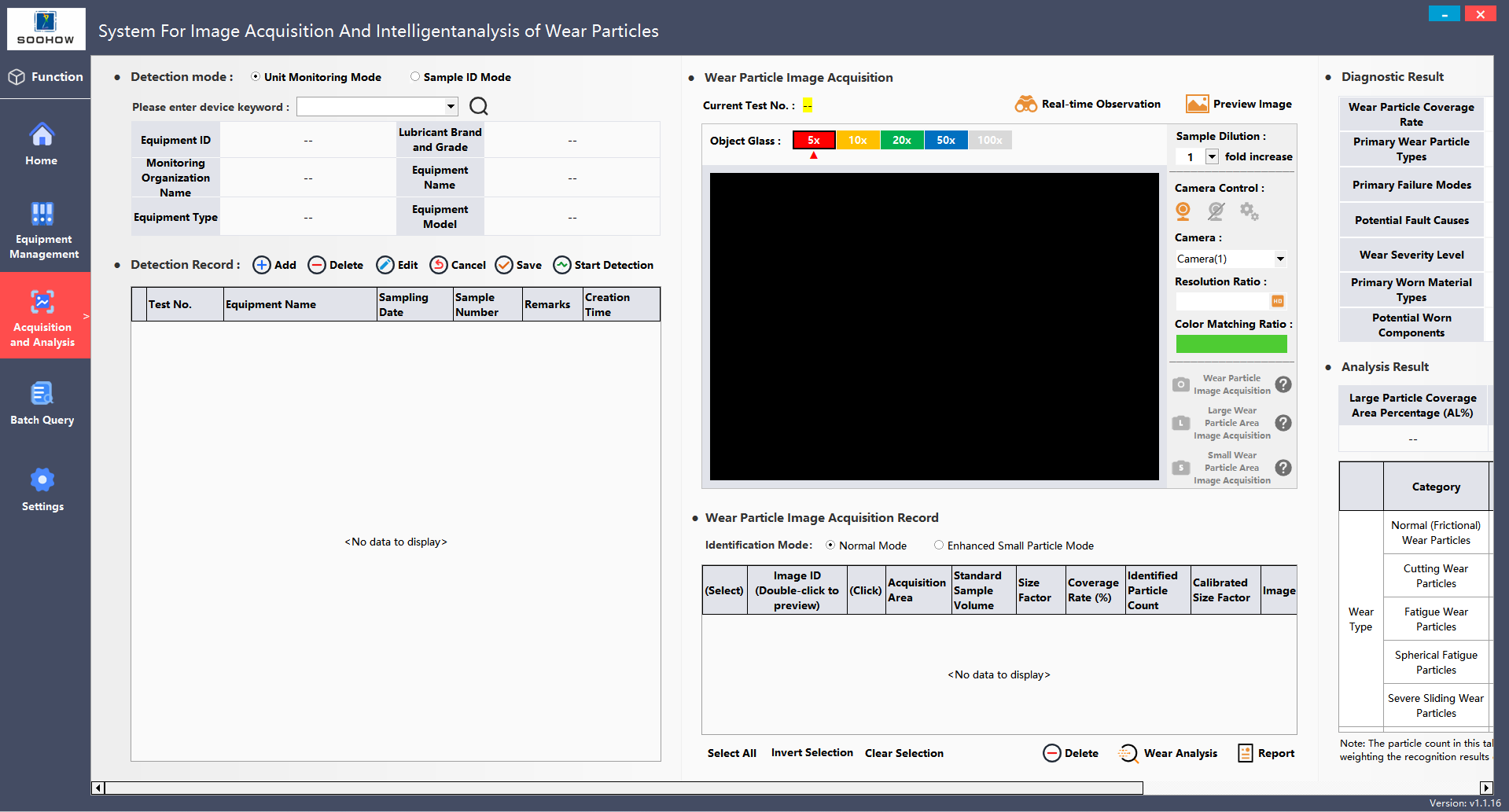

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

موارد الصناعة

لا تتوفر موارد

نقوم حالياً بتحديث مكتبة الموارد لهذه الصناعة. عد قريباً أو اتصل بنا لطلب وثائق محددة.

طلب الوثائقالمنتجات الداعمة

Oil Analysis

Oil Analysis

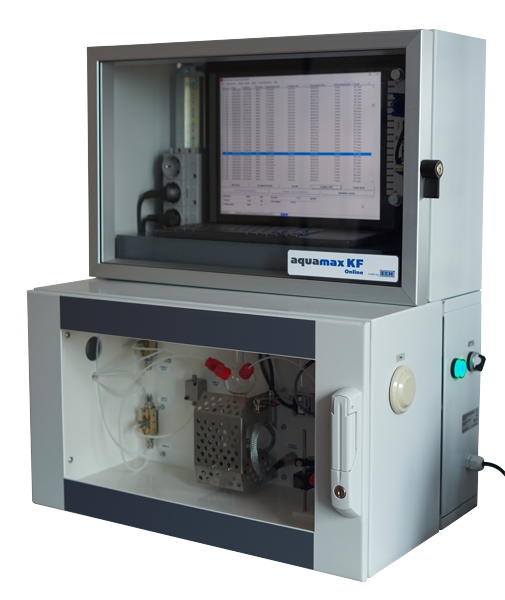

أكواماكس KF أونلاين

Aquamax KF Online هو نظام معايرة Karl Fischer أوتوماتيكي عالي الأداء...

Oil Analysis

Oil Analysis

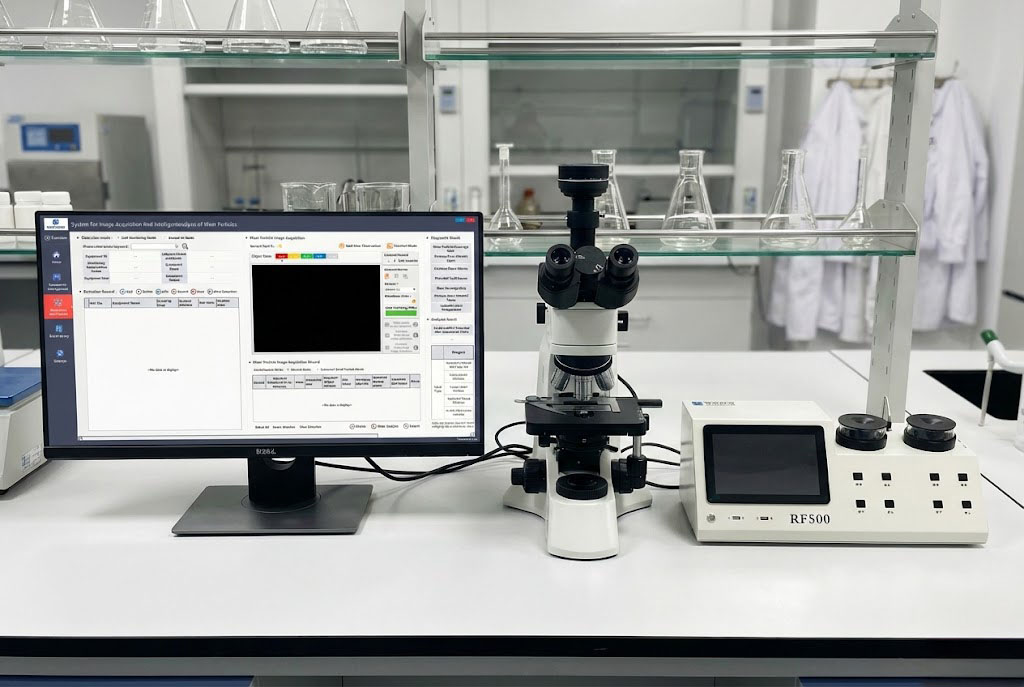

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

مقياس الحديد PF100

PF100 هو جهاز قياس الحديد المغناطيسي المحمول مصمم للكشف ا...

Oil Analysis

Oil Analysis

سلسلة ليزر نت 200

سلسلة LaserNet 200 هي نظام متقدم آلي لتحليل الجسيمات مصمم لا�...

Oil Analysis

Oil Analysis

ميني فيسك 3000

MiniVisc 3000 هو مقياس لزوجة حركية محمول ثوري يوفر قياسات لزو...

Oil Analysis

Oil Analysis

عداد جسيمات الزيت المحمول SLPC300

جهاز SLPC300 هو عداد جسيمات زيت محمول يستخدم مبدأ حجب الضو�...

Oil Analysis

Oil Analysis

ترو ڤيو 360

TruVu™ 360 هو منصة برمجية تشخيصية خاصة بشركة Spectro Scientific مصم...

Oil Analysis

Oil Analysis

نظام الحصول على صور جزيئات التآكل والتحليل الذكي المدعوم بالذكاء الاصطناعي

This advanced system is a cutting-edge solution for modern Ferrography and oil condition monitoring....

مستعد للعثور على الحل المناسب؟

يمكن لفريقنا مساعدتك في اختيار المنتجات المثالية لتطبيقات Railways التطبيقات