Main

Oil Analysis

Diagnostic Software

TruVu™ 360

Part #:

TruVu™ 360

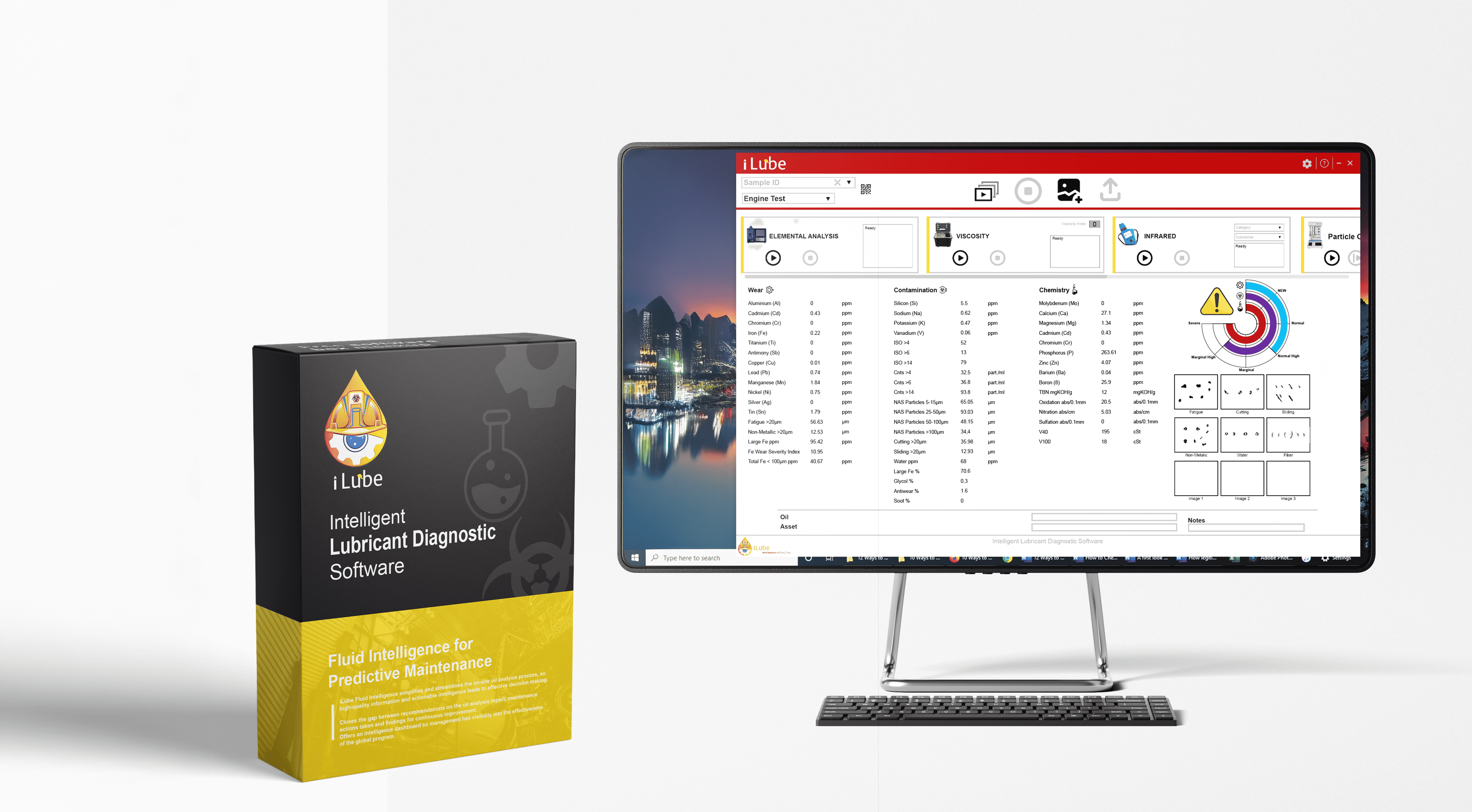

TruVu™ 360 is Spectro Scientific’s proprietary diagnostic software platform designed to integrate and manage data from its family of MiniLab instruments. It automates the workflow of oil sampling, testing, diagnosis, and reporting—allowing users to make fast, accurate maintenance decisions directly from the field or lab.

The system includes the signature Trivector™ Dashboard, which visually maps oil condition in three dimensions: Wear, Contamination, and Chemistry, offering an intuitive overview of machine health status.

The system includes the signature Trivector™ Dashboard, which visually maps oil condition in three dimensions: Wear, Contamination, and Chemistry, offering an intuitive overview of machine health status.

Trivector™ Dashboard

Displays a 3-axis health summary of lubricant condition, visually identifying whether the issue is related to wear, contamination, or chemistry changes.

Integrated with Spectro MiniLab Series

Works seamlessly with Spectroil, LaserNet, FluidScan, MiniVisc, and FerroCheck devices, combining their test data into a single unified report.

Automated Workflows

From sample log-in to report delivery, TruVu automates the complete testing and diagnostics process—including alarm evaluation and maintenance recommendations.

Asset Health Tracking

Stores historical test results per asset and enables trend analysis, threshold monitoring, and predictive alerts.

Maintenance-Focused Outputs

Presents not just raw results, but actionable maintenance guidance based on customizable limits and rules.

| Specification | Value |

|---|---|

| Compatible Devices | Spectroil 120, LaserNet 200, MiniVisc 3000, FluidScan 1100, FerroCheck 2000 |

| Signature Feature | Trivector |

| Reporting Formats | PDF, Excel, On-screen dashboards |

| Data Sources | Direct from MiniLab instruments |

| Supported Languages | English (localized versions available upon request) |

| Deployment | Desktop application (Windows), optionally networked |

| Integration | Optional data export to external systems (manual or custom setup) |