Main

Oil Analysis

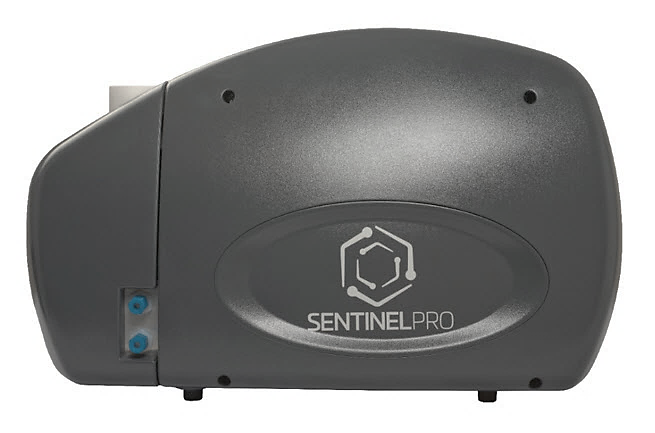

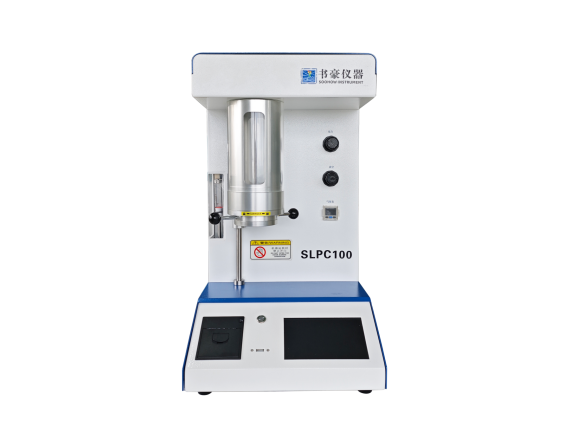

Particle Counter

LaserNet 200 Series

Part #:

Q200

The LaserNet 200 Series is an advanced, automated particle analysis system designed to detect, classify, and image wear debris in used oils. Utilizing laser imaging and sophisticated software, the system not only counts particles according to ISO 4406 but also provides insight into machine wear conditions by identifying particle types (ferrous, non-ferrous, fibers, etc.). It is ideal for predictive maintenance programs in industrial and military applications.

Key Features

ISO 4406 cleanliness code reporting

Ferrous Wear Severity Index (FWSI)

Laser imaging of individual particles

Wear mode classification: cutting, sliding, fatigue

Non-metallic particle detection

High throughput: ~2 minutes per sample

Integration with condition monitoring software like iLube and TruVu 360

These features make the LaserNet 200 a comprehensive tool for condition-based maintenance programs and failure prevention.

Ferrous Wear Severity Index (FWSI)

Laser imaging of individual particles

Wear mode classification: cutting, sliding, fatigue

Non-metallic particle detection

High throughput: ~2 minutes per sample

Integration with condition monitoring software like iLube and TruVu 360

These features make the LaserNet 200 a comprehensive tool for condition-based maintenance programs and failure prevention.

Automatic shape classification features

Unlike basic particle counters, the LaserNet 200 doesn’t just count—it understands. Through advanced laser imaging, the system captures real-time images of each particle and uses AI-based shape recognition to classify debris into wear categories.

The system identifies:

Ferrous vs. non-ferrous metals

Large cutting particles (severe wear)

Sliding wear (thin flakes)

Rolling fatigue particles (gears, bearings)

Fibers, dirt, and non-metallic contaminants

This classification allows users to not only know there is a problem—but understand what kind of problem it is, and where it likely comes from.

The system identifies:

Ferrous vs. non-ferrous metals

Large cutting particles (severe wear)

Sliding wear (thin flakes)

Rolling fatigue particles (gears, bearings)

Fibers, dirt, and non-metallic contaminants

This classification allows users to not only know there is a problem—but understand what kind of problem it is, and where it likely comes from.

False Alarm Reduction

One of the common issues with traditional particle counters is false alarms caused by harmless fibers, water droplets, or air bubbles. The LaserNet 200 eliminates these by using shape recognition and visual validation. You don’t just get an alarm—you see what triggered it.

This helps maintenance teams avoid unnecessary interventions and focus only on real risks.

This helps maintenance teams avoid unnecessary interventions and focus only on real risks.

Real Particle Imaging

Each particle is captured in high resolution and saved in the analysis report. These images can be reviewed for manual verification or archived for trend comparison. This visual history is a major asset in predictive maintenance.

Integrated Diagnostics and Software Support

LaserNet 200 works seamlessly with diagnostic software like iLube and TruVu 360, where results are interpreted, visualized, and translated into actionable maintenance plans. From raw data to a full diagnostic report with recommendations—it’s a complete analytical ecosystem.

| Specification | Value |

|---|---|

| Particle Size Range | Range 20 – 100 µm |

| Particle Count Range | Up to 20,000 particles/mL |

| Sample Volume Required | Approx. 10 mL per test |

| Analysis Time | ~2 minutes per sample |

| Imaging Technology | High-resolution real-time laser imaging |

| Output Parameters | ISO 4406 code, total count, wear classification, FWSI, particle images |

| Wear Classification Types | Cutting, Sliding, Rolling Fatigue, Non-metallic, Fibers |

| Supported Fluid Types | Lubricants, hydraulic oils, turbine oils, engine and gear oils |

| Communication Interfaces | Ethernet, USB |

| Software Compatibility | TruVu 360, iLube, custom LIMS integration |

| Calibration Method | Factory-calibrated; verification with standards available |

| Operating Temperature Range | 15°C – 35°C |

| Power Requirements | 100–240 V AC, 50/60 Hz |

| Dimensions (L x W x H) | Approx. 18 x 24 x 20 in (457 x 610 x 508 mm) |

| Weight | Approx. 65 lbs (29.5 kg) |

Datasheet