Power Generation

Power plants are expected to operate 24 hours per day, 7 days per week. Downtime and equipment derating (when a generator fails to deliver power at its rated capacity) can cost a p...

行业概览

Power plants are expected to operate 24 hours per day, 7 days per week. Downtime and equipment derating (when a generator fails to deliver power at its rated capacity) can cost a power plant thousands of dollars per hour. The cost of replacing failed equipment is also extremely high. Vibration analysis by itself is not enough to anticipate catastrophic failures. Oil analysis is often able to detect problems at a much earlier stage than vibration analysis. This is why more and more power plants are bringing oil analysis capabilities in house.\r\n\r\n

主要特点

Power plants are expected to operate 24 hours per day, 7 days per week. Downtime and equipment derating (when a generator fails to deliver power at its rated capacity) can cost a power plant thousands of dollars per hour. The cost of replacing failed equipment is also extremely high. Vibration analysis by itself is not enough to anticipate catastrophic failures. Oil analysis is often able to detect problems at a much earlier stage than vibration analysis. This is why more and more power plants are bringing oil analysis capabilities in house.

Machine condition monitoring based on oil analysis is widely practiced by power plants, whether they are nuclear, coal-fired steam, combined cycle gas turbine, medium and low speed diesels, windmills, or geothermal. All of these plants have critical turbines, pumps, bearings, fans, compressors, gears and hydraulic systems. Failure of critical equipment may cause plant shutdown at great cost.

Power plant oil samples are typically tested for elemental content to determine wear metals, contaminants and additives. FT-IR analysis is used to determine lubricant degradation and fluid contamination (i.e., water, fuel glycol). Viscosity testing is done to insure the right oil is being used and to make sure it is still fit for use.

Particle counting and trending gives early warning about wear conditions before vibration analysis can detect issues. Ferrous monitoring can determine when wear is getting worse in a piece of equipment. This tests are invaluable for predicting wear problems that will cause downtime if early intervention isn't planned.

Machine condition monitoring based on oil analysis is widely practiced by power plants, whether they are nuclear, coal-fired steam, combined cycle gas turbine, medium and low speed diesels, windmills, or geothermal. All of these plants have critical turbines, pumps, bearings, fans, compressors, gears and hydraulic systems. Failure of critical equipment may cause plant shutdown at great cost.

Power plant oil samples are typically tested for elemental content to determine wear metals, contaminants and additives. FT-IR analysis is used to determine lubricant degradation and fluid contamination (i.e., water, fuel glycol). Viscosity testing is done to insure the right oil is being used and to make sure it is still fit for use.

Particle counting and trending gives early warning about wear conditions before vibration analysis can detect issues. Ferrous monitoring can determine when wear is getting worse in a piece of equipment. This tests are invaluable for predicting wear problems that will cause downtime if early intervention isn't planned.

典型测试与应用

Particle counting A measure of oil cleanliness, particle counting is a critical test for hydraulics, turbines and filtered gearboxes. This test has evolved to be more than a measure of effective filtration. Newer technologies such as LaserNet Fines count particles and report to ISO 4406 or SAE AS 4059.

Water contamination is the most common liquid contaminant in power plants, and should always be monitored. Excessive water destroys a lubricant’s ability to separate opposing moving parts, allowing severe wear to occur. For most equipment water contamination should not exceed 0.25%, and not more than 100 ppm for turbine lube and control systems.

Kinematic Viscosity is a lubricant’s most important physical property. Lubricants must have suitable flow characteristics so an adequate supply reaches lubricated parts at different operating temperatures. Their viscosities vary depending on classification, grade, oxidation and contamination. In power plants, viscosity is routinely measured right after an oil change to confirm the correct oil was added, as well as on a periodic basis.

Total Acid Number (TAN) indicates relative acidity. Oil changes are often indicated when the TAN value reaches a predetermined level.

Wear

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

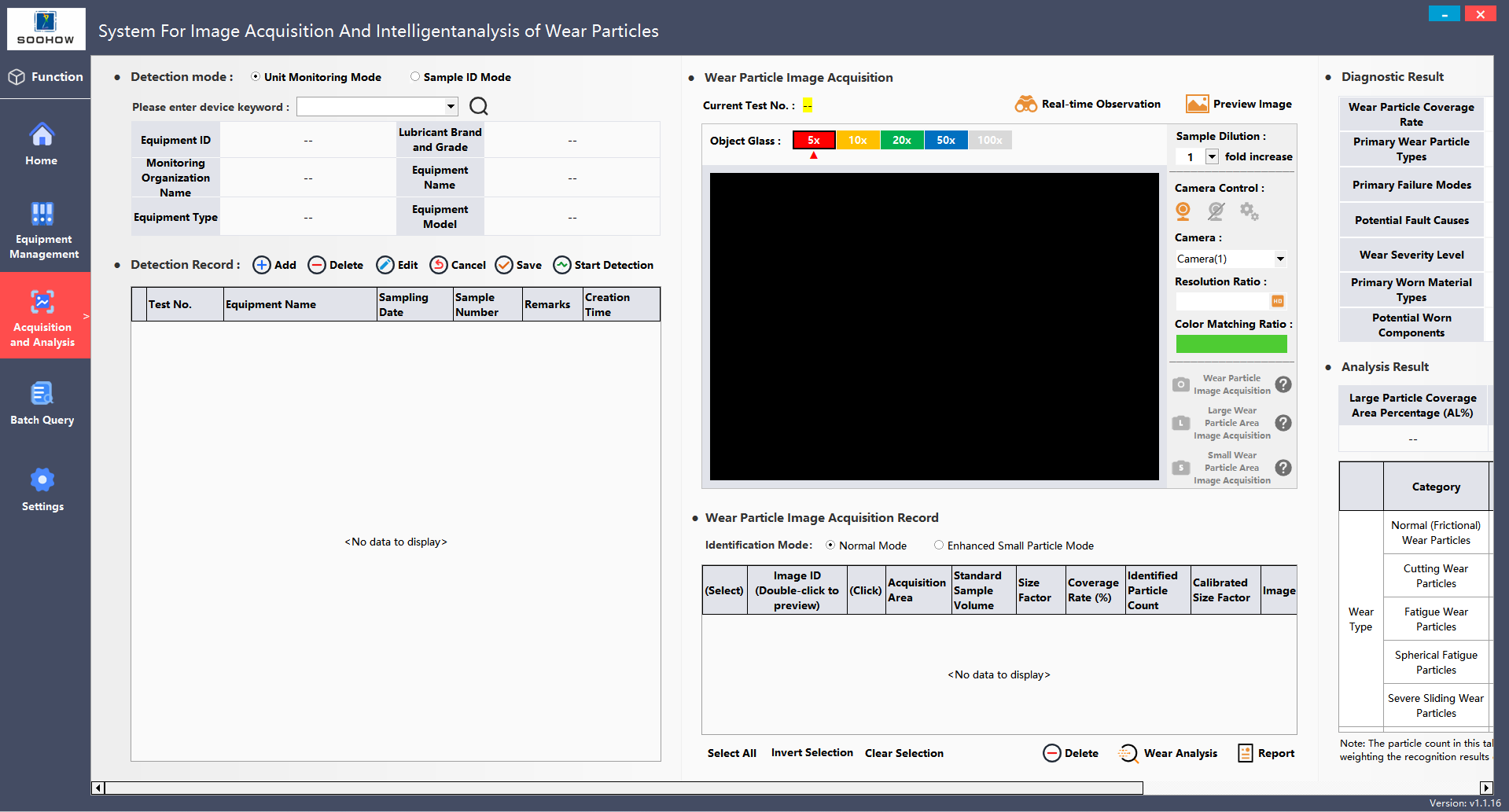

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry and Viscosity

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Oxidation, Nitration, Sulfation - Lubricating oil at elevated temperatures can react with oxygen and nitrogen in the atmosphere, as well as sulfur in fuel, to form undesirable by-products that can affect the oil's viscosity and lead to corrosion or damage of equipment.

Contamination

Water - Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

Water contamination is the most common liquid contaminant in power plants, and should always be monitored. Excessive water destroys a lubricant’s ability to separate opposing moving parts, allowing severe wear to occur. For most equipment water contamination should not exceed 0.25%, and not more than 100 ppm for turbine lube and control systems.

Kinematic Viscosity is a lubricant’s most important physical property. Lubricants must have suitable flow characteristics so an adequate supply reaches lubricated parts at different operating temperatures. Their viscosities vary depending on classification, grade, oxidation and contamination. In power plants, viscosity is routinely measured right after an oil change to confirm the correct oil was added, as well as on a periodic basis.

Total Acid Number (TAN) indicates relative acidity. Oil changes are often indicated when the TAN value reaches a predetermined level.

Wear

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry and Viscosity

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Oxidation, Nitration, Sulfation - Lubricating oil at elevated temperatures can react with oxygen and nitrogen in the atmosphere, as well as sulfur in fuel, to form undesirable by-products that can affect the oil's viscosity and lead to corrosion or damage of equipment.

Contamination

Water - Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

行业资源

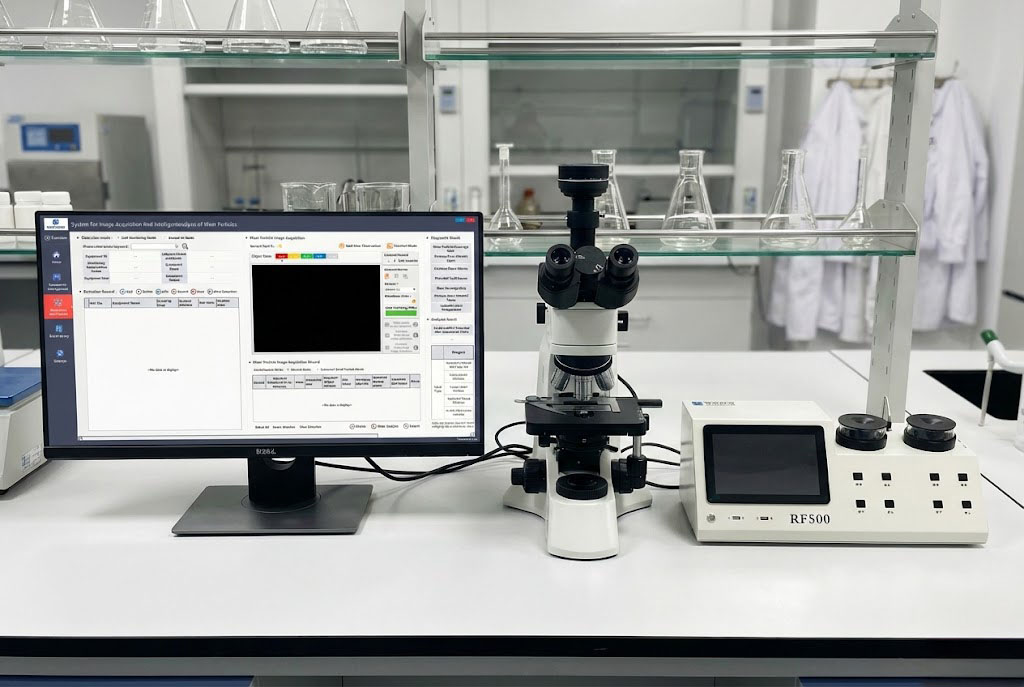

支持产品

Oil Analysis

Oil Analysis

准备找到正确的解决方案?

我们的团队可以帮助您为您的应用选择完美的产品 Power Generation 应用