Power Generation

Aperçu de l'Industrie

Caractéristiques Clés

Machine condition monitoring based on oil analysis is widely practiced by power plants, whether they are nuclear, coal-fired steam, combined cycle gas turbine, medium and low speed diesels, windmills, or geothermal. All of these plants have critical turbines, pumps, bearings, fans, compressors, gears and hydraulic systems. Failure of critical equipment may cause plant shutdown at great cost.

Power plant oil samples are typically tested for elemental content to determine wear metals, contaminants and additives. FT-IR analysis is used to determine lubricant degradation and fluid contamination (i.e., water, fuel glycol). Viscosity testing is done to insure the right oil is being used and to make sure it is still fit for use.

Particle counting and trending gives early warning about wear conditions before vibration analysis can detect issues. Ferrous monitoring can determine when wear is getting worse in a piece of equipment. This tests are invaluable for predicting wear problems that will cause downtime if early intervention isn't planned.

Tests et Applications Typiques

Water contamination is the most common liquid contaminant in power plants, and should always be monitored. Excessive water destroys a lubricant’s ability to separate opposing moving parts, allowing severe wear to occur. For most equipment water contamination should not exceed 0.25%, and not more than 100 ppm for turbine lube and control systems.

Kinematic Viscosity is a lubricant’s most important physical property. Lubricants must have suitable flow characteristics so an adequate supply reaches lubricated parts at different operating temperatures. Their viscosities vary depending on classification, grade, oxidation and contamination. In power plants, viscosity is routinely measured right after an oil change to confirm the correct oil was added, as well as on a periodic basis.

Total Acid Number (TAN) indicates relative acidity. Oil changes are often indicated when the TAN value reaches a predetermined level.

Wear

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry and Viscosity

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Oxidation, Nitration, Sulfation - Lubricating oil at elevated temperatures can react with oxygen and nitrogen in the atmosphere, as well as sulfur in fuel, to form undesirable by-products that can affect the oil's viscosity and lead to corrosion or damage of equipment.

Contamination

Water - Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

Ressources de l'Industrie

Pas de Ressources Disponibles

Nous mettons à jour notre bibliothèque de ressources pour cette industrie. Revenez bientôt ou contactez-nous pour demander une documentation spécifique.

Demander une DocumentationProduits de Support

Oil Analysis

Oil Analysis

Ferrographe rotatif double RF500

Le RF500 est un ferrographe rotatif à double tête conçu pour l’analyse qualitative et quantitat...

Oil Analysis

Oil Analysis

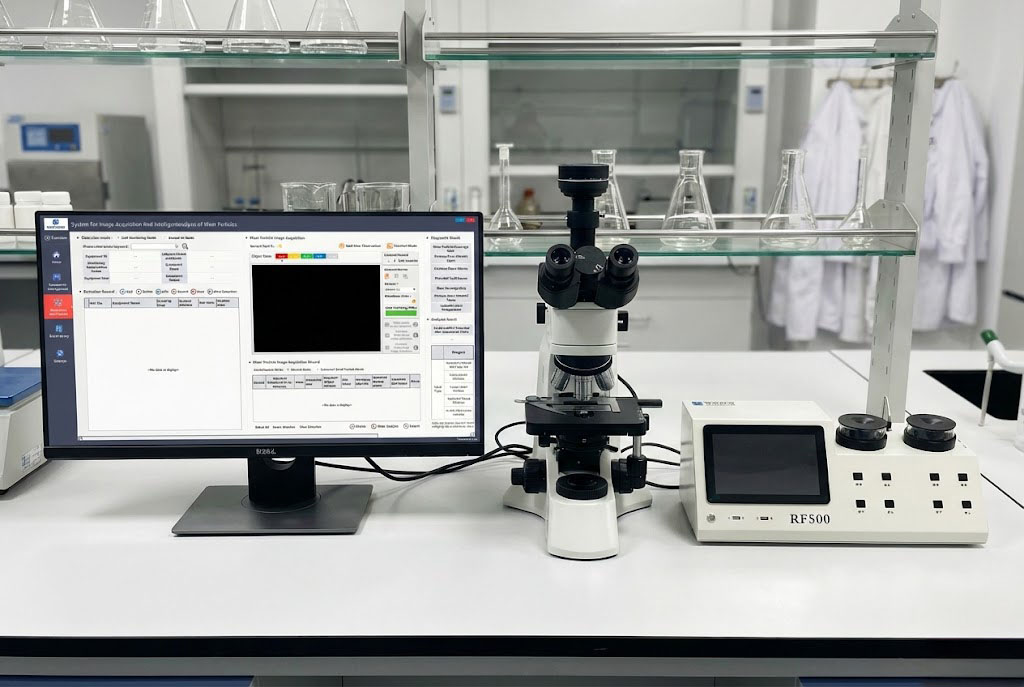

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

Série LaserNet 200

La série LaserNet 200 est un système avancé et automatisé d’analyse des particules conçu pour...

Oil Analysis

Oil Analysis

MiniVisc 3000

Le MiniVisc 3000 est un viscosimètre cinématique portable révolutionnaire qui fournit des mesures...

Oil Analysis

Oil Analysis

Pi Sentinel PRO

Le SentinelPro est un analyseur d’images dynamiques haute performance conçu pour les applications...

Oil Analysis

Oil Analysis

Viscosimètre cinématique portable VS800

Le viscosimètre cinématique portable VS800 est un outil de mesure de viscosité de précision, pol...

Oil Analysis

Oil Analysis

Échantillonneur de pression positive et négative PC‑VES

Le PC‑VES est un échantillonneur d’huile portable à pression positive/négative conçu pour le...

Oil Analysis

Oil Analysis

R4 RotrOil (changeur d’échantillons automatique)

Le R4 RotrOil est une version avancée et entièrement automatisée du spectromètre élémentaire R...

Oil Analysis

Oil Analysis

RotrOil

Le RotrOil est le spectromètre d’émission optique à électrode à disque rotatif (RDE-OES) de d...

Oil Analysis

Oil Analysis

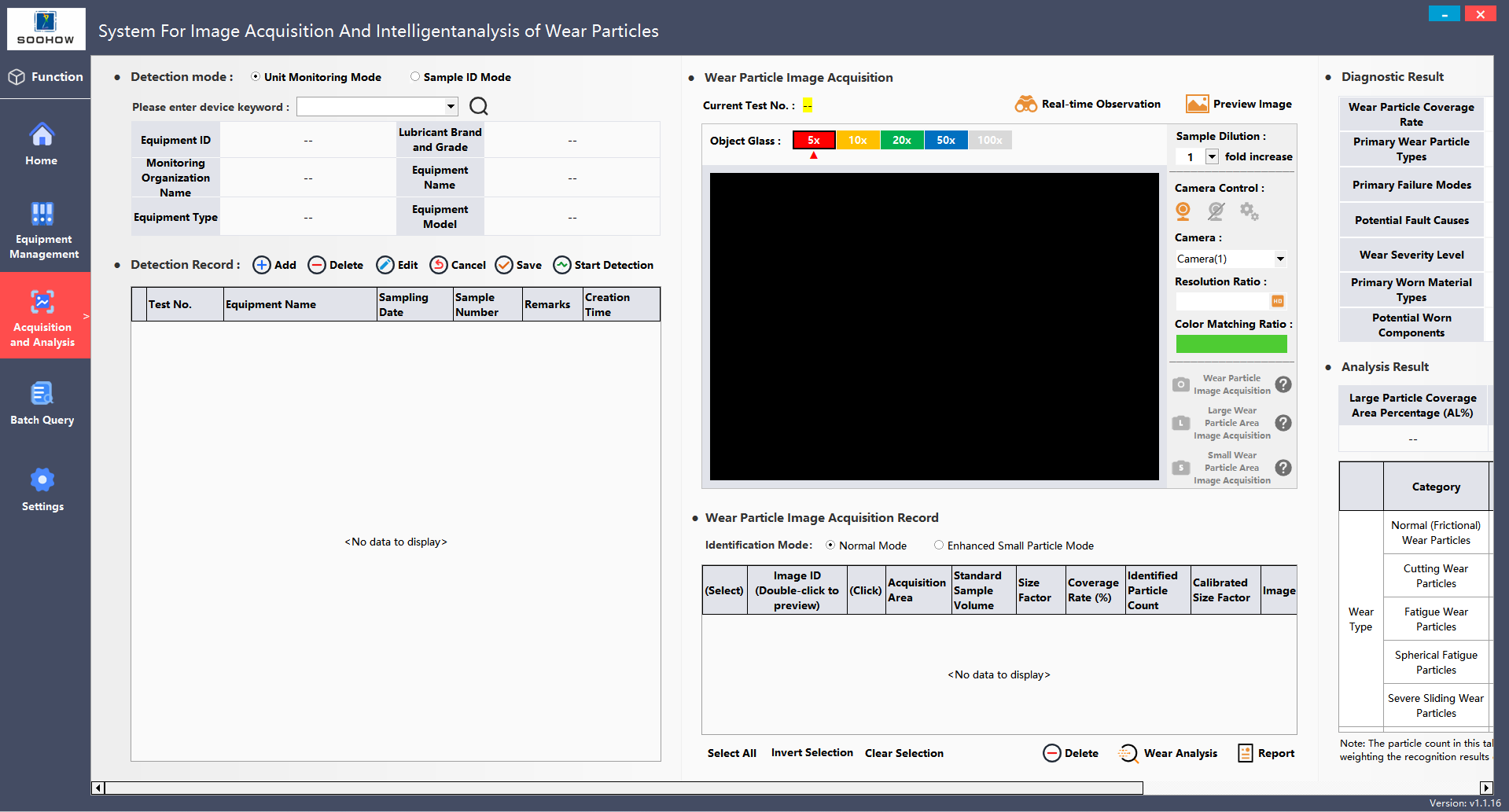

Système d'Acquisition d'Images et d'Analyse Intelligente des Particules d'Usure (Propulsé par l'IA)

Description du Produit Ce système avancé est une solution de pointe pour la ferrographie moderne e...

Prêt à Trouver la Bonne Solution?

Notre équipe peut vous aider à sélectionner les produits parfaits pour vos Power Generation applications