Main

Oil Analysis

Wear Particle Analysis

Dual rotating ferrograph RF500

Part #:

RF500

The RF500 is a dual-head rotating ferrograph designed for qualitative and quantitative analysis of ferrous wear particles in used lubricating oils and fluids. It meets Chinese industry standards (NB/T 51068‑2017 and Q‑SH.J 014‑2010) and features dual magnetic deposition, adjustable rotation speed, a wide particle size detection range, and integrated video imaging. The system is ideal for monitoring machine wear trends and predicting mechanical failures in heavy-duty industrial and transportation applications.

Dual Rotating Magnetic Deposition

Uses dual magnetic heads to capture ferrous particles efficiently—even from highly contaminated oil samples—onto a glass slide for ferrogram analysis.

High-Gradient Magnetic Field

Magnetic field strength from 100–1000 Gauss with working points ≥ 600 Gs allows graded deposition of particles by size and magnetic strength.

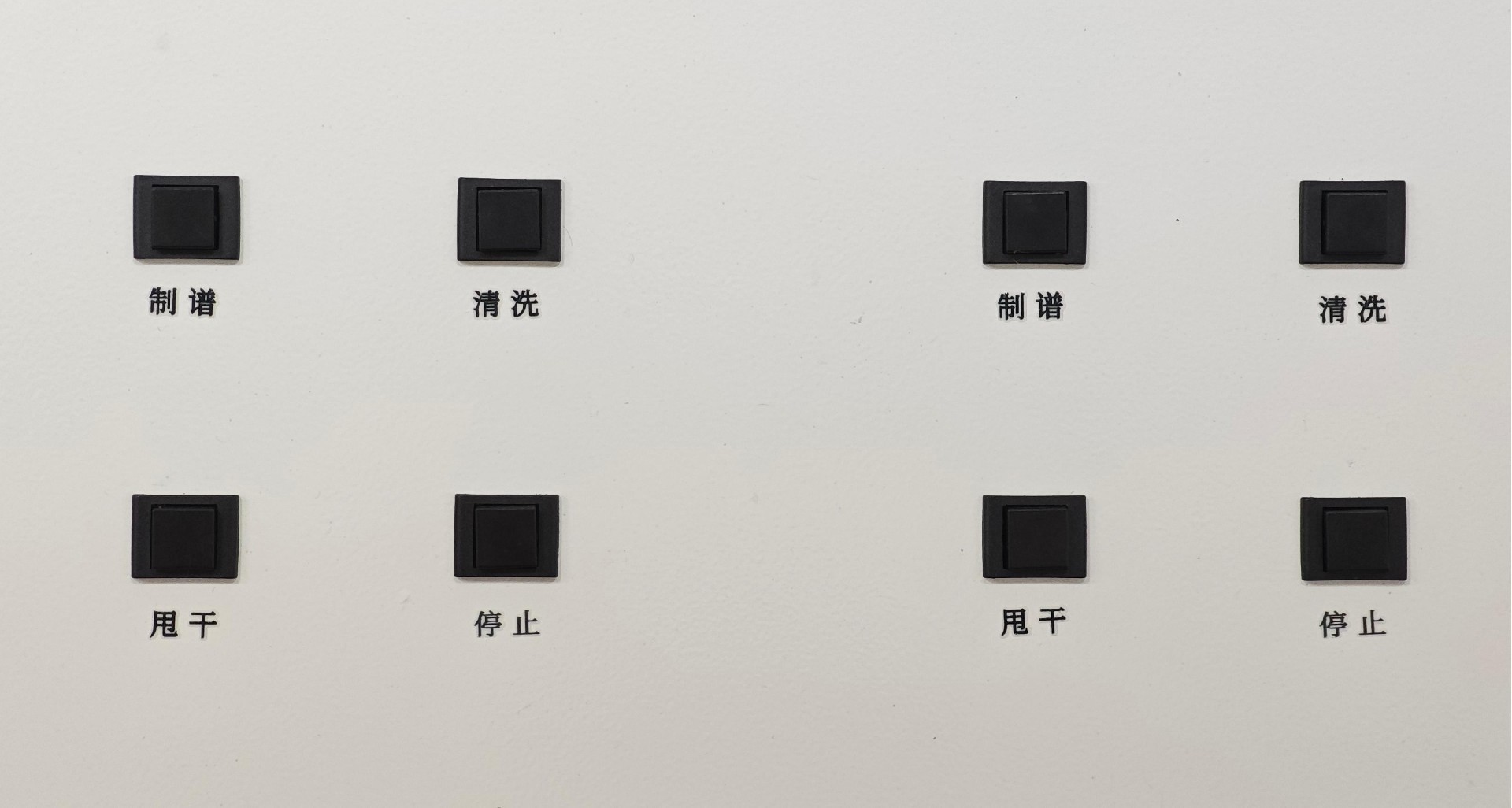

Adjustable Speeds for Each Stage

Customizable rotation speeds: 75 rpm (deposition), 150 rpm (cleaning), and 200 rpm (spin drying), all programmable via a built-in 10.1″ touchscreen.

Wide Particle Size Detection

Detects particles ranging from submicron up to 3000 µm, with reproducibility within ±10% (qualitative) and ±15% (quantitative).

Integrated Imaging System

Includes a dual-path optical microscope with a 16 MP high-definition camera and desktop PC for wear pattern visualization and data archiving.

| Specification | Value |

|---|---|

| Magnetic Field Strength | 100–1000 Gauss; working ≥600 Gs |

| Magnetic Head Dimensions | Inner Ø11.5 mm; Coil Ø19 mm; Outer Ø29 mm |

| Rotation Speeds | 75 rpm (deposition), 150 rpm (cleaning), 200 rpm (drying) |

| Particle Size Range | 0–3000 µm |

| Reproducibility Error | <10% (qualitative), <15% (quantitative) |

| Slide Substrate | 55 × 55 × 0.17 mm glass slide |

| Dimensions | 700 × 280 × 240 mm |

| Weight | ~14 kg |

| Power Supply | AC 220 V ±10%, 50 Hz; Output: 24 V / 6 A |

| Power Consumption | <150 W |

| Control Panel | Push buttons + 10.1 LCD touchscreen |

| Motor Control | Dual-stepper motors with independent speed control |

| Sample Handling | Automatic injection and pump-based recovery system |

| Power Failure Protection | Automatic memory and resume feature |

| Imaging System | Dual-light microscope, 16 MP camera, PC & software included |