Aviation, Aerospace

Aperçu de l'Industrie

Caractéristiques Clés

Challenges

Aircraft must live up to extremely high expectations for readiness and reliability while operating in extremes of temperature, pressure and humidity. Because of these demands, the engines must be maintained at top performance which drives the need for early detection and correction of engine and lubricant anomalies. Compounding this is the fact that aircraft are often at a given location for a limited period of time before being routed to the next destination. Therefore mechanics need very sensitive measurements of lubricant and component condition with results available in minutes so that they may take the proper action while the aircraft is still in the hangar.

Synthetic Polyol Ester fluids are the fluids of choice to lubricate aircraft gas turbine engines used in commercial and military service requiring MIL-PRF-23699F-STD level performance. It also is used for aircraft-type gas turbine engines in industrial or marine service applications. These synthetic lubricants are formulated to meet the demanding requirements of aircraft type gas turbines operating over a wide range of severe operating conditions. They have excellent thermal and oxidation stability to reduce sludge and varnish deposits and they have a high specific heat. The lubricants also retain viscosity and film strength over a wide temperature range (-40°C to 204° C or -40°F to 400°F).

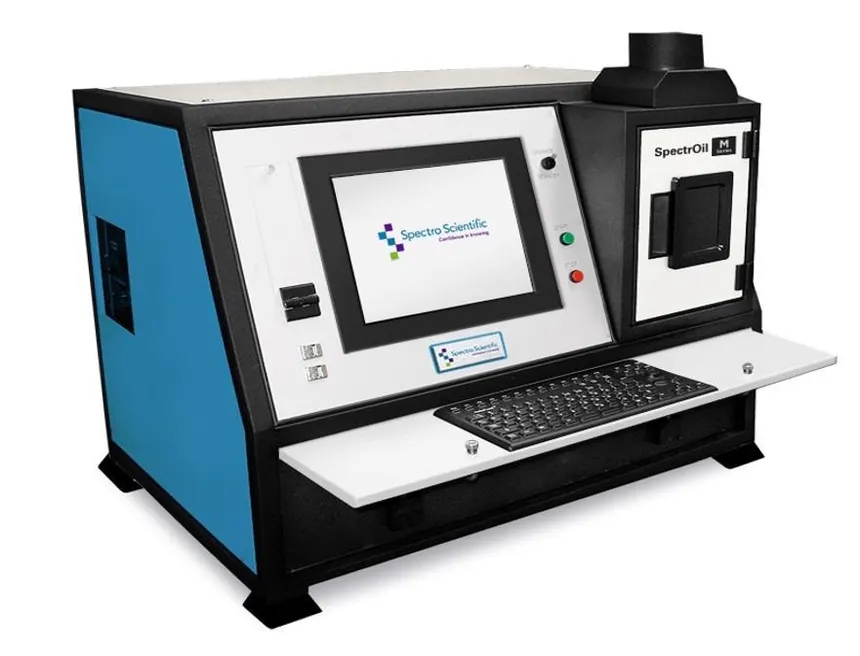

These types of lubricants can exhibit confounding matrix effects when they are analyzed for particles using Optical Emission Spectroscopy. The SpectrOil M accounts for these effects by allowing the user to create custom calibrations to counter these matrix effects, enabling accurate measurement of wear particles.

Tests et Applications Typiques

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Viscosity - The main function of lubricating oil is to create and maintain a lubrication film between two moving metal surfaces. Ensuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Ressources de l'Industrie

Pas de Ressources Disponibles

Nous mettons à jour notre bibliothèque de ressources pour cette industrie. Revenez bientôt ou contactez-nous pour demander une documentation spécifique.

Demander une DocumentationProduits de Support

Oil Analysis

Oil Analysis

Ferrographe rotatif double RF500

Le RF500 est un ferrographe rotatif à double tête conçu pour l’analyse qualitative et quantitat...

Oil Analysis

Oil Analysis

Série FluidScan® 1000

Le FluidScan est un spectromètre infrarouge portable utilisé pour l’analyse de l’état des hui...

Oil Analysis

Oil Analysis

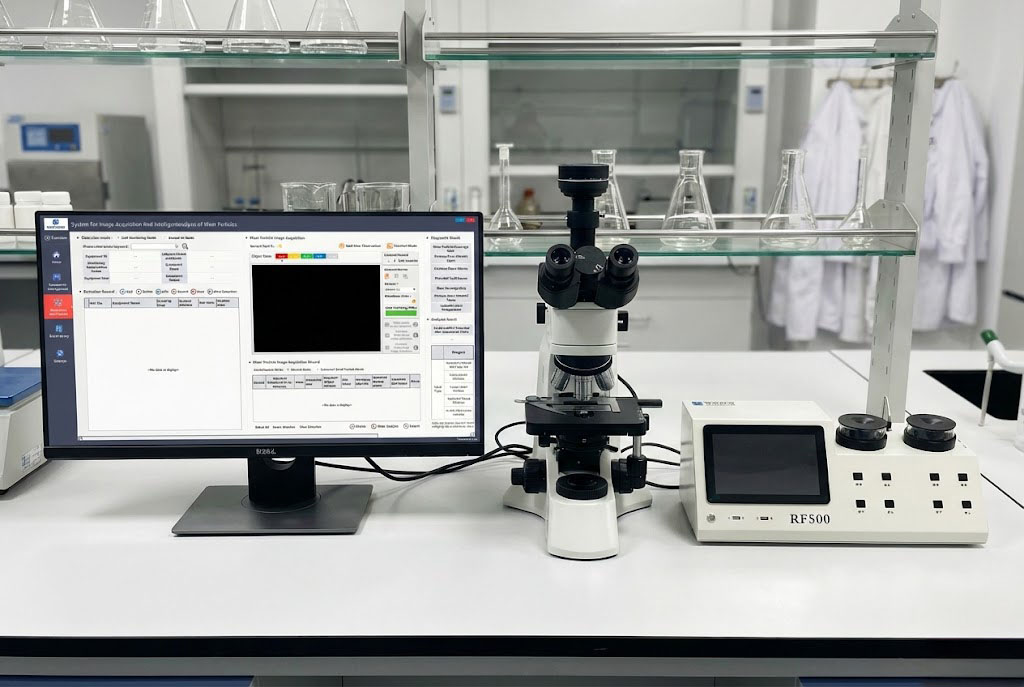

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

Testeur de rigidité diélectrique d’huile isolante JKJQ‑1

Le JKJQ‑1 est un testeur de rigidité diélectrique entièrement automatique conçu pour évaluer ...

Oil Analysis

Oil Analysis

Testeur de rigidité diélectrique d’huile isolante JKJQ‑1A

Le JKJQ‑1A est un testeur portable entièrement automatique à une seule coupelle conçu pour mesu...

Oil Analysis

Oil Analysis

Testeur de rigidité diélectrique JKJQ‑3

Le JKJQ‑3 est un testeur de claquage diélectrique à coupelle unique entièrement automatique, co...

Oil Analysis

Oil Analysis

Série LaserNet 200

La série LaserNet 200 est un système avancé et automatisé d’analyse des particules conçu pour...

Oil Analysis

Oil Analysis

MiniVisc 3000

Le MiniVisc 3000 est un viscosimètre cinématique portable révolutionnaire qui fournit des mesures...

Oil Analysis

Oil Analysis

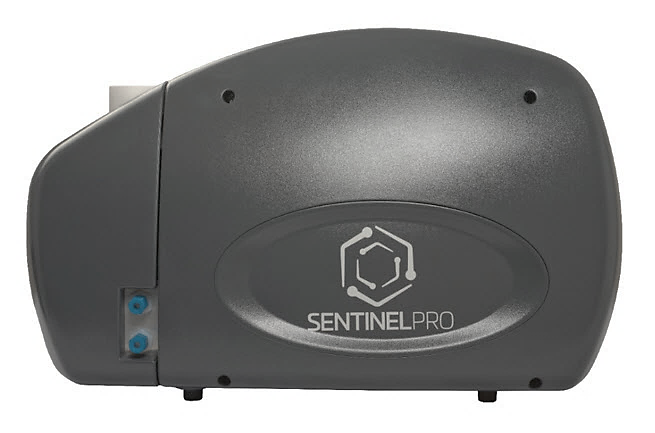

Pi Sentinel PRO

Le SentinelPro est un analyseur d’images dynamiques haute performance conçu pour les applications...

Oil Analysis

Oil Analysis

Viscosimètre cinématique portable VS800

Le viscosimètre cinématique portable VS800 est un outil de mesure de viscosité de précision, pol...

Oil Analysis

Oil Analysis

Compteur de particules d’huile portable SLPC300

Le SLPC300 est un compteur de particules d’huile portable qui utilise le principe de blocage de la...

Oil Analysis

Oil Analysis

Échantillonneur de pression positive et négative PC‑VES

Le PC‑VES est un échantillonneur d’huile portable à pression positive/négative conçu pour le...

Oil Analysis

Oil Analysis

Série SpectrOil M

La série SpectrOil M est un spectromètre d’émission optique à électrode à disque rotatif (RD...

Oil Analysis

Oil Analysis

Viscosimètre portable à mouvement rapide VS600

Le viscosimètre cinématique portable VS600 est un instrument de terrain haute efficacité conçu p...

Prêt à Trouver la Bonne Solution?

Notre équipe peut vous aider à sélectionner les produits parfaits pour vos Aviation, Aerospace applications