ایوی ایشن، ایرو اسپیس

صنعت کا جائزہ

اہم خصوصیات

Challenges

Aircraft must live up to extremely high expectations for readiness and reliability while operating in extremes of temperature, pressure and humidity. Because of these demands, the engines must be maintained at top performance which drives the need for early detection and correction of engine and lubricant anomalies. Compounding this is the fact that aircraft are often at a given location for a limited period of time before being routed to the next destination. Therefore mechanics need very sensitive measurements of lubricant and component condition with results available in minutes so that they may take the proper action while the aircraft is still in the hangar.

Synthetic Polyol Ester fluids are the fluids of choice to lubricate aircraft gas turbine engines used in commercial and military service requiring MIL-PRF-23699F-STD level performance. It also is used for aircraft-type gas turbine engines in industrial or marine service applications. These synthetic lubricants are formulated to meet the demanding requirements of aircraft type gas turbines operating over a wide range of severe operating conditions. They have excellent thermal and oxidation stability to reduce sludge and varnish deposits and they have a high specific heat. The lubricants also retain viscosity and film strength over a wide temperature range (-40°C to 204° C or -40°F to 400°F).

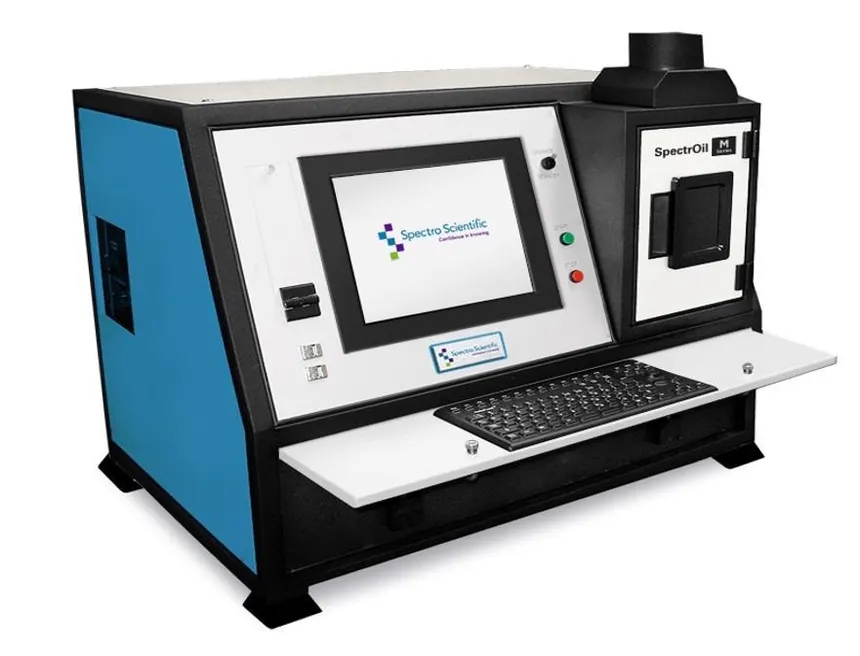

These types of lubricants can exhibit confounding matrix effects when they are analyzed for particles using Optical Emission Spectroscopy. The SpectrOil M accounts for these effects by allowing the user to create custom calibrations to counter these matrix effects, enabling accurate measurement of wear particles.

عام ٹیسٹ اور ایپلی کیشنز

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Viscosity - The main function of lubricating oil is to create and maintain a lubrication film between two moving metal surfaces. Ensuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

صنعتی وسائل

کوئی وسائل دستیاب نہیں

ہم فی الحال اس صنعت کے لیے اپنی وسائل کی لائبریری کو اپ ڈیٹ کر رہے ہیں۔ جلد ہی دوبارہ چیک کریں یا مخصوص دستاویزات کی درخواست کرنے کے لیے ہم سے رابطہ کریں۔

دستاویزی درخواست کریںمعاون مصنوعات

Oil Analysis

Oil Analysis

ڈوئل روٹیٹنگ فیروگراف RF500

RF500 ایک ڈوئل ہیڈ روٹیٹنگ فیراگراف ہے جو استعمال شدہ چکن�...

Oil Analysis

Oil Analysis

فلوئیڈ اسکین 1000 سیریز (FluidScan® 1000 Series)

فلوڈ اسکین ایک ہینڈ ہیلڈ انفراریڈ اسپیکٹرو میٹر ہے جو س...

Oil Analysis

Oil Analysis

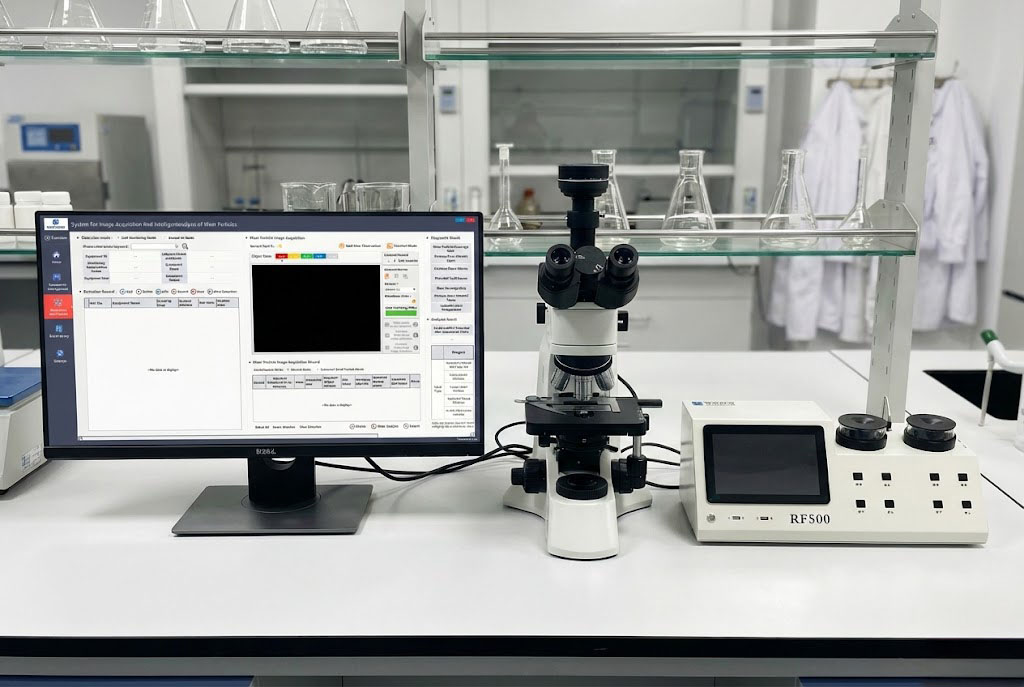

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

JKJQ-1 انسولیٹنگ آئل ڈائی الیکٹرک اسٹرینتھ ٹیسٹر

JKJQ-1 ایک خودکار ڈائی الیکٹرک اسٹرینتھ ٹیسٹر ہے جو برقی آ...

Oil Analysis

Oil Analysis

JKJQ-1A انسولیٹنگ آئل ڈائی الیکٹرک اسٹرینتھ ٹیسٹر

JKJQ-1A ایک مکمل خودکار، سنگل کپ ٹیسٹر ہے جو ٹرانسفارمرز م�...

Oil Analysis

Oil Analysis

JKJQ-3 ڈائی الیکٹرک اسٹرینتھ ٹیسٹر

JKJQ-3 ایک مکمل خودکار ٹیسٹر ہے جو ٹرانسفارمر اور کپیسٹر آ...

Oil Analysis

Oil Analysis

لیزر نیٹ 200 سیریز (LaserNet 200 Series)

لیزر نیٹ 200 سیریز ایک جدید خودکار پارٹیکل تجزیہ نظام ہے ...

Oil Analysis

Oil Analysis

منی وسک 3000 (MiniVisc 3000)

منی ویسک 3000 ایک انقلابی پورٹیبل کینیمیٹک ویسکومیٹر ہے �...

Oil Analysis

Oil Analysis

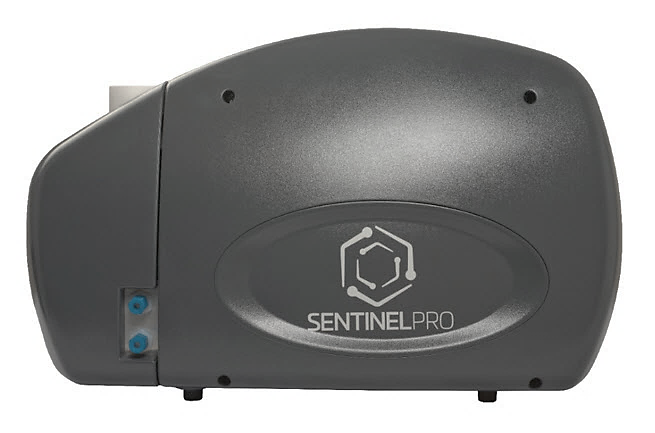

پائی سینٹینل پرو (Pi Sentinel PRO)

SentinelPro ایک اعلی کارکردگی کا حامل متحرک تصویری تجزیہ کار...

Oil Analysis

Oil Analysis

پورٹیبل کائینیٹک وسکومیٹر VS800

VS800 پورٹیبل کینیمیٹک ویسکومیٹر ایک درست، کثیر مقصدی وا�...

Oil Analysis

Oil Analysis

پورٹیبل آئل پارٹیکل کاؤنٹر SLPC300

SLPC300 ایک پورٹیبل آئل پارٹیکل کاؤنٹر ہے جو مختلف سیالوں �...

Oil Analysis

Oil Analysis

مثبت اور منفی پریشر سیمپلر PC‑VES

PC-VES ایک پورٹیبل مثبت/منفی پریشر آئل سیمپلر ہے جو زیادہ �...

Oil Analysis

Oil Analysis

سپیکٹرآئل M سیریز (SpectrOil M Series)

اسپیکٹروآئل M سیریز ایک کمپیکٹ اور قابل اعتماد RDE-OES اسپ�...

Oil Analysis

Oil Analysis

VS600 پورٹیبل ریپڈ موشن وسکومیٹر

VS600 پورٹیبل ریپڈ موشن ویسکومیٹر ایک اعلی کارکردگی کا فی...

صحیح حل تلاش کرنے کے لیے تیار ہیں؟

ہماری ٹیم آپ کی مدد کر سکتی ہے بہترین مصنوعات منتخب کرنے میں برائے ایوی ایشن، ایرو اسپیس ایپلی کیشنز