Food and Beverage

Manufacturers of food and beverages typically have a high volume of product passing through their facilities at all times. For this reason, any unexpected downtime can be very cost...

行业概览

Manufacturers of food and beverages typically have a high volume of product passing through their facilities at all times. For this reason, any unexpected downtime can be very costly in terms of lost production. In addition, many food and beverage facilities have difficult challenges associated with lubricant contamination.\r\n

主要特点

Manufacturers of food and beverages typically have a high volume of product passing through their facilities at all times. For this reason, any unexpected downtime can be very costly in terms of lost production. In addition, many food and beverage facilities have difficult challenges associated with lubricant contamination.

Many of these facilities have a lot of water or steam being used to clean and sterilize products and packaging. Water can get into the lubrication oil and become a very troublesome contaminant. Facilities also often deal with airborne contaminants like sugar and other fine, powdery foods that can contaminate oils.

Often there are special oils used that comply with NSF standard like H1, H2 and H3. So any oil analysis must be able to handle these specialty lubricants.

Challenges

Water is one of the worst contaminants for lubrication oil. Water contamination can greatly affect the oil’s viscosity and can also lead to rusting of machine components. Traditional methods for measuring water contamination, like Karl Fischer titration, can be costly, time-consuming and impossible to use outside of a laboratory environment.

Fortunately water contamination can be measured quickly and easily using the FluidScan. The FluidScan requires only a couple drops of oil and one minute to run the analysis. Results compare quite favorably with laboratory Karl Fischer results without the need for special training, solvents and dangerous acids.

Many of these facilities have a lot of water or steam being used to clean and sterilize products and packaging. Water can get into the lubrication oil and become a very troublesome contaminant. Facilities also often deal with airborne contaminants like sugar and other fine, powdery foods that can contaminate oils.

Often there are special oils used that comply with NSF standard like H1, H2 and H3. So any oil analysis must be able to handle these specialty lubricants.

Challenges

Water is one of the worst contaminants for lubrication oil. Water contamination can greatly affect the oil’s viscosity and can also lead to rusting of machine components. Traditional methods for measuring water contamination, like Karl Fischer titration, can be costly, time-consuming and impossible to use outside of a laboratory environment.

Fortunately water contamination can be measured quickly and easily using the FluidScan. The FluidScan requires only a couple drops of oil and one minute to run the analysis. Results compare quite favorably with laboratory Karl Fischer results without the need for special training, solvents and dangerous acids.

典型测试与应用

Contamination of oil is big problem. Contamination can come in the form of debris and wear particles, but water can also be a critical contaminant. The cost of downtime is extremely high in food processing plants. Therefore quick turnaround of test results is essential to keeping a plant up and running. On-site oil analysis gives answers in minutes.

Wear

Particle count- a high particle count or a rapid increase in particles can foreshadow an imminent failure.

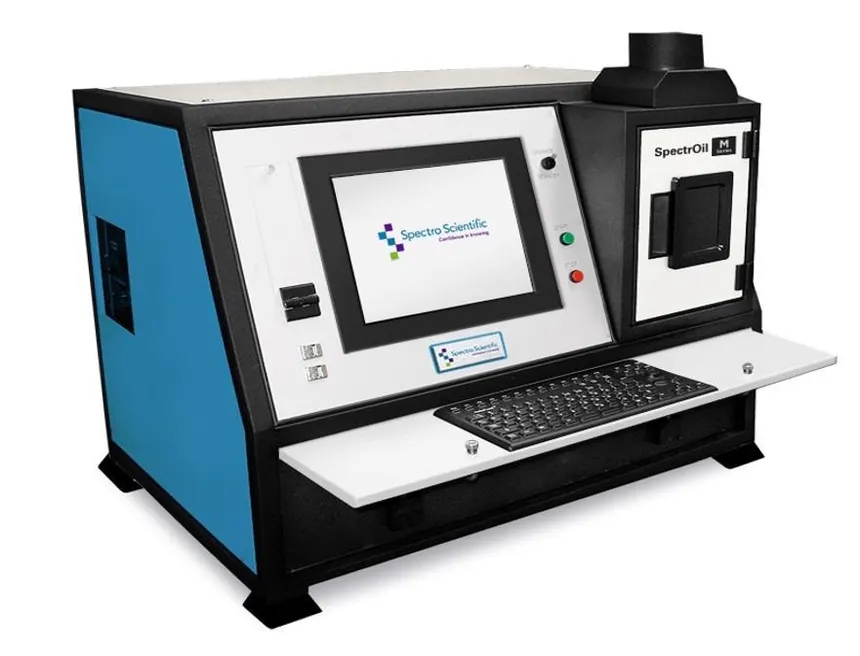

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

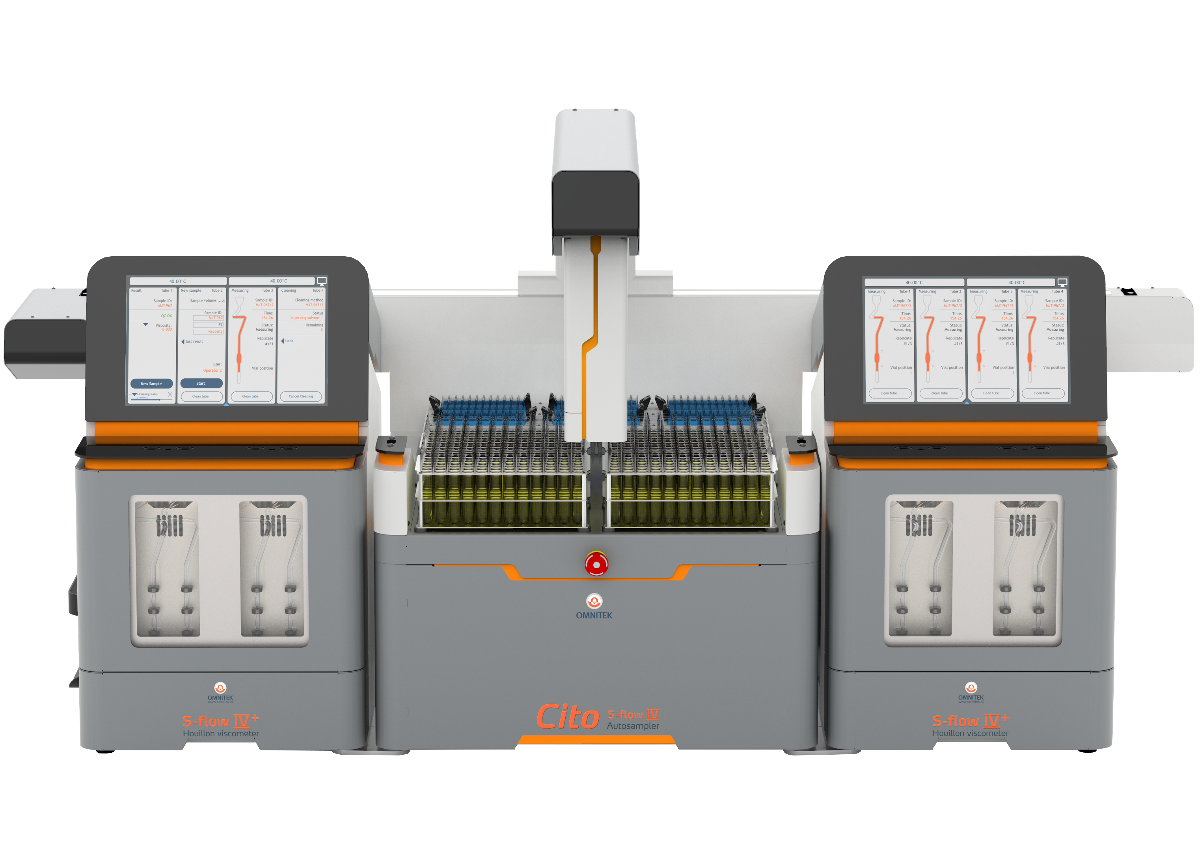

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Contamination

Water- Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

Wear

Particle count- a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Contamination

Water- Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

行业资源

支持产品

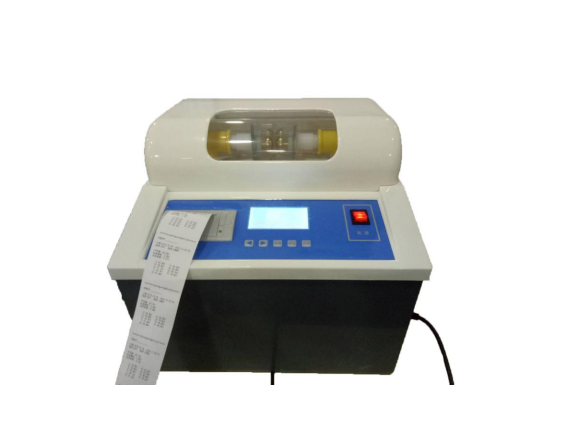

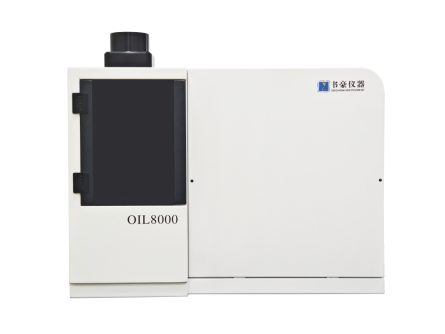

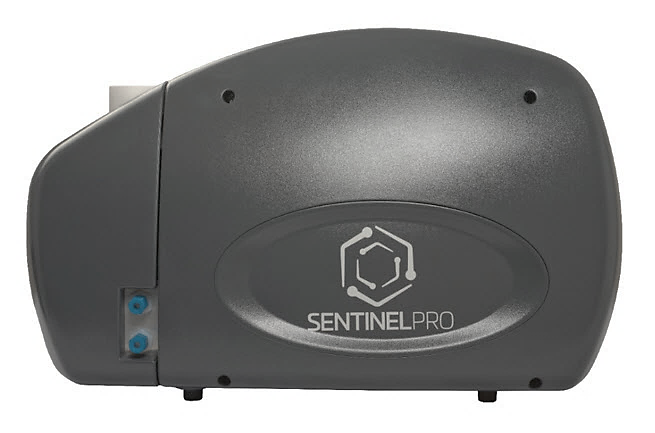

Oil Analysis

Oil Analysis

Oil Analysis

Oil Analysis

Oil Analysis

Oil Analysis

Contact Angle & Surface Tension

Contact Angle & Surface Tension

Oil Analysis

Oil Analysis

Oil Analysis

Oil Analysis

准备找到正确的解决方案?

我们的团队可以帮助您为您的应用选择完美的产品 Food and Beverage 应用