Kelautan / Maritim

Ikhtisar Industri

Fitur Utama

Challenges

Being at sea for long periods of time makes the use of on-shore oil analysis labs impractical for marine vessels. By the time results are received back on board the equipment being analyzed might have failed already.

offers a set of solutions to transform the vessel owner’s onboard oil analysis program. As instrumentation size decreases and becomes more portable, oil analysis devices are now being put in the hands of the end user. It has been proven that these new smaller devices do not sacrifice analytical performance. This brings the end user closer to the vessel and its problems, enabling time-sensitive, critical decision making.

Cold Corrosion - Large, two-stroke diesel engines are used in over 30,000 ships worldwide. Due to over lubrication, they waste in excess of US$2 billion of cylinder oil every year. This creates more than 1.25 million tons of contaminated drain oil that needs proper disposal. This over-lubrication in slow speed, two-stroke marine diesel engines can cost ship managers and owners more than $100,000 per year per ship.

Cylinder under-lubrication leads to cold corrosion and early failure of expensive engine components like pistons, piston rings and cylinder liners. Careful monitoring of cylinder oil BN allows the operator to use enough oil to prevent cold corrosion without wasting valuable oil and additives.

Tes & Aplikasi Khas

Wear

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Chemistry

Total Base Number (TBN) - TBN measures the amount of active additive left in a sample of oil. The TBN is useful for people who want to extend their oil usage far beyond the normal range. The TBN of a used oil can aid the user in determining how much reserve additive the oil has left to neutralize acids. The lower the TBN reading, the less active additive the oil has left.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Oxidation, Nitration, Sulfation - Lubricating oil at elevated temperatures can react with oxygen and nitrogen in the atmosphere, as well as sulfur in fuel, to form undesirable by-products that can affect the oil's viscosity and lead to corrosion or damage of equipment.

Contamination

Fuel Dilution - Fuel dilution in oil is a condition caused by excess, unburned fuel mixing with engine oil in an engine crankcase. Hydrocarbon-based fuel, usually with a lower vapor pressure than the lubricant, has a thinning effect, lowering the oil viscosity. Oil film strength is reduced, increasing the cylinder liner and bearing wear.

Glycol - Glycol is found in engine coolant. If glycol is found in engine oil it typically indicates there is a leak in the engine that can cause catastrophic damage to the cylinder or cylinder wall.

Water - Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

Sumber Daya Industri

Tidak Ada Sumber Daya Tersedia

Kami sedang memperbarui perpustakaan sumber daya kami untuk industri ini. Periksa kembali segera atau hubungi kami untuk meminta dokumentasi khusus.

Minta DokumentasiProduk Pendukung

Oil Analysis

Oil Analysis

Aquamax KF PRO LPG

Ini adalah titrator khusus untuk menentukan kadar air dalam gas minyak cair (LPG).

Oil Analysis

Oil Analysis

Ferograf Pembacaan Langsung DR100

DR100 adalah ferrograf benchtop yang menawarkan kuantifikasi otomatis dan cepat dari partikel aus be...

Oil Analysis

Oil Analysis

Seri FluidScan® 1000

FluidScan adalah spektrometer inframerah genggam yang digunakan untuk analisis kondisi oli di lokasi...

Oil Analysis

Oil Analysis

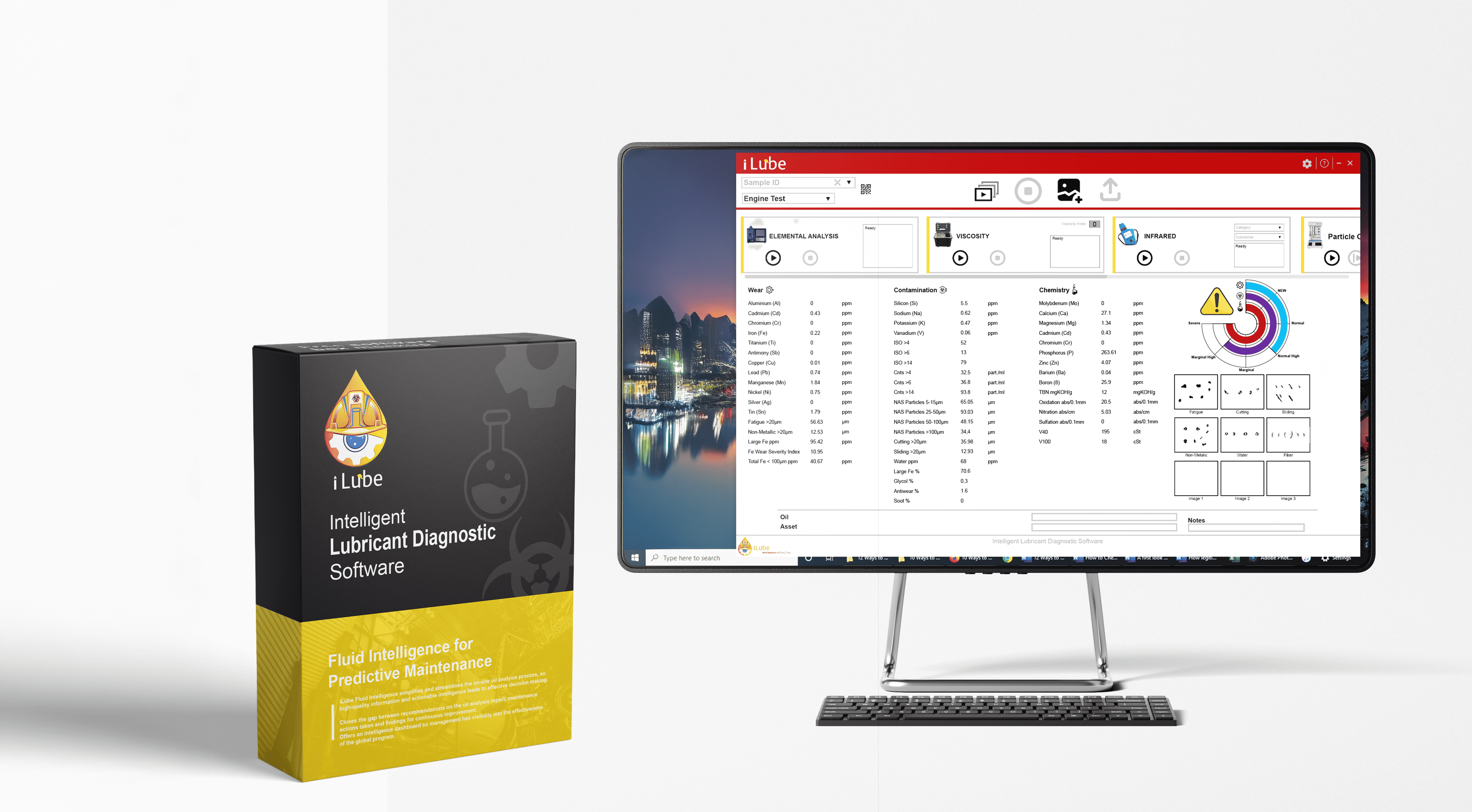

iLube – Diagnostik Pelumas Cerdas

iLube adalah platform perangkat lunak analisis oli yang cerdas, fleksibel, dan multibahasa, dirancan...

Oil Analysis

Oil Analysis

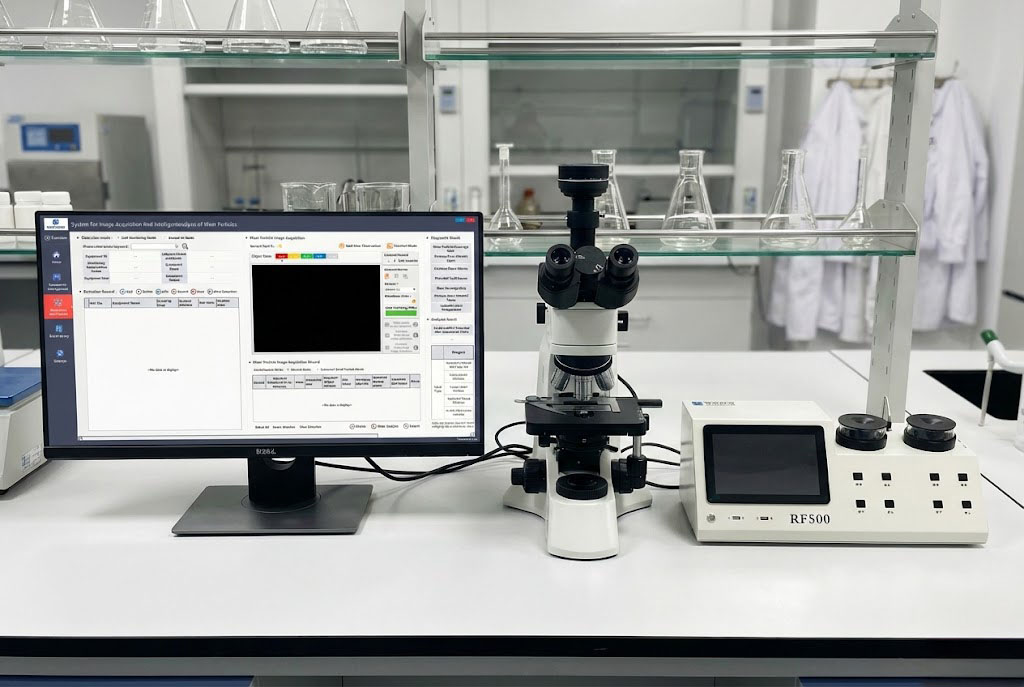

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

Penganalisis Oli Cerdas IOA8000

IOA8000 adalah penganalisis fluoresensi sinar-X dispersif energi (EDXRF) portabel dan mudah digunaka...

Oil Analysis

Oil Analysis

Penguji Kekuatan Dielektrik Oli Isolasi JKJQ‑1A

JKJQ-1A adalah penguji cangkir tunggal otomatis penuh yang dirancang untuk mengukur kekuatan dielekt...

Oil Analysis

Oil Analysis

Seri LaserNet 200

LaserNet 200 Series adalah sistem analisis partikel otomatis canggih yang dirancang untuk mendeteksi...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

MBP – Tensiometer Tekanan Gelembung

MBP 200 menggunakan metode tekanan gelembung maksimum untuk mengukur tegangan permukaan dinamis laru...

Oil Analysis

Oil Analysis

Seri MicroLab

Seri MicroLab adalah sistem analisis oli di lokasi yang sepenuhnya otomatis, dirancang untuk memberi...

Oil Analysis

Oil Analysis

MiniVisc 3000

MiniVisc 3000 adalah viskometer kinematik portabel inovatif yang memberikan pengukuran viskositas ti...

Oil Analysis

Oil Analysis

Pi Raptor Portable

Raptor Portable Dry Powder Analyzer adalah sistem portabel pertama yang membawa analisis gambar dina...

Oil Analysis

Oil Analysis

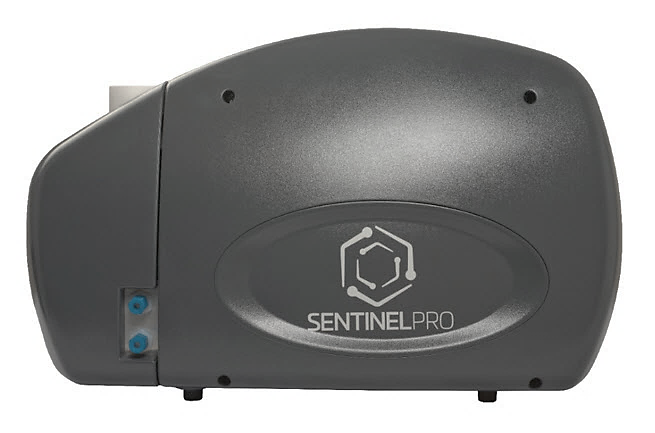

Pi Sentinel PRO

SentinelPro adalah penganalisis gambar dinamis berkinerja tinggi untuk aplikasi di mana bentuk parti...

Oil Analysis

Oil Analysis

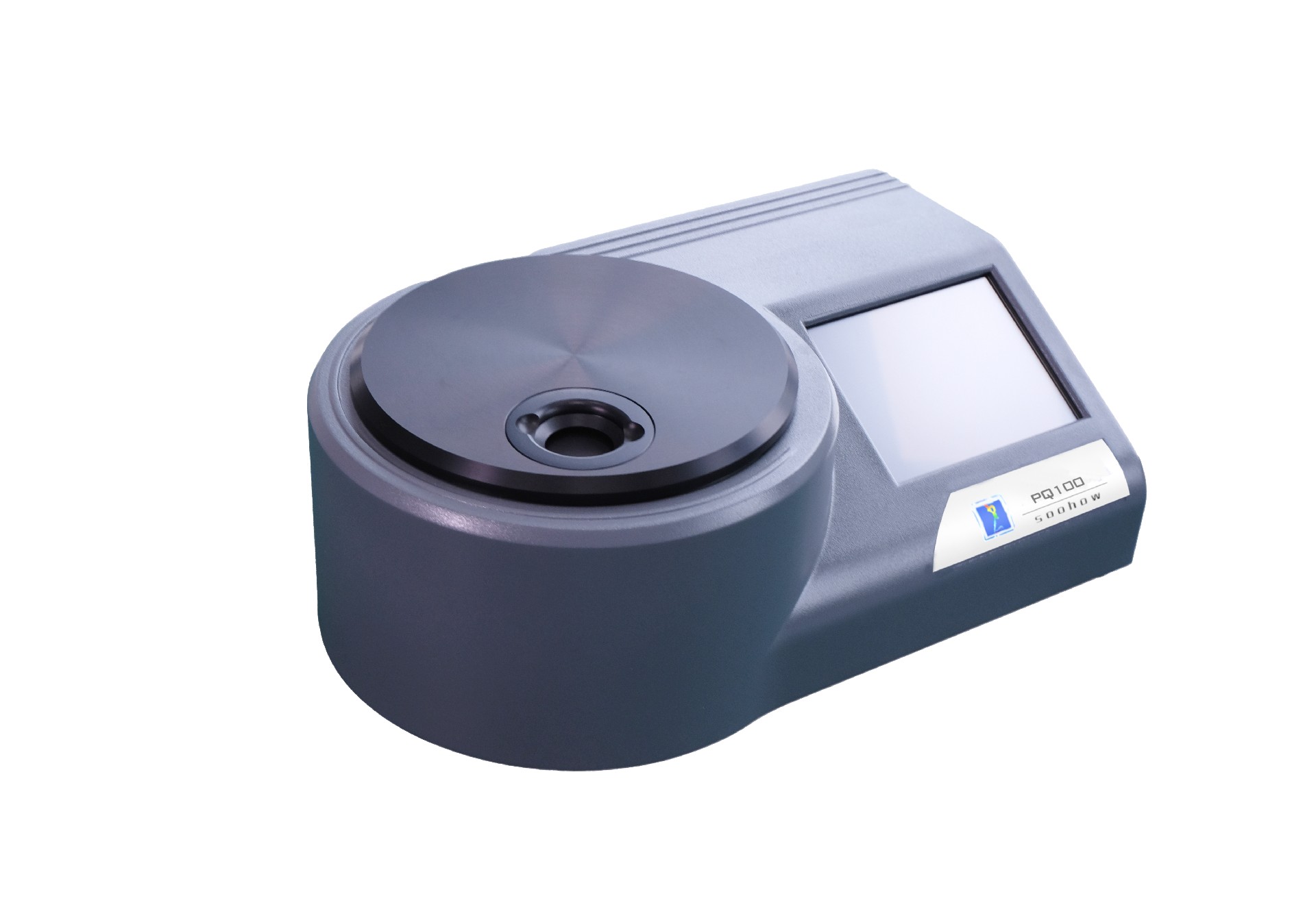

Penganalisis Keausan Feromagnetik PQL PQ100

PQ100 adalah perangkat portabel ringkas untuk deteksi cepat dan kuantifikasi partikel feromagnetik d...

Oil Analysis

Oil Analysis

RotrOil

RotrOil adalah RDE-OES generasi terbaru dari GNR yang disesuaikan untuk analisis elemen yang cepat d...

Oil Analysis

Oil Analysis

Smart Lu C

Smart Lu C adalah sistem MiniLab yang ringkas dan siap pakai di lapangan yang menggabungkan tiga ala...

Oil Analysis

Oil Analysis

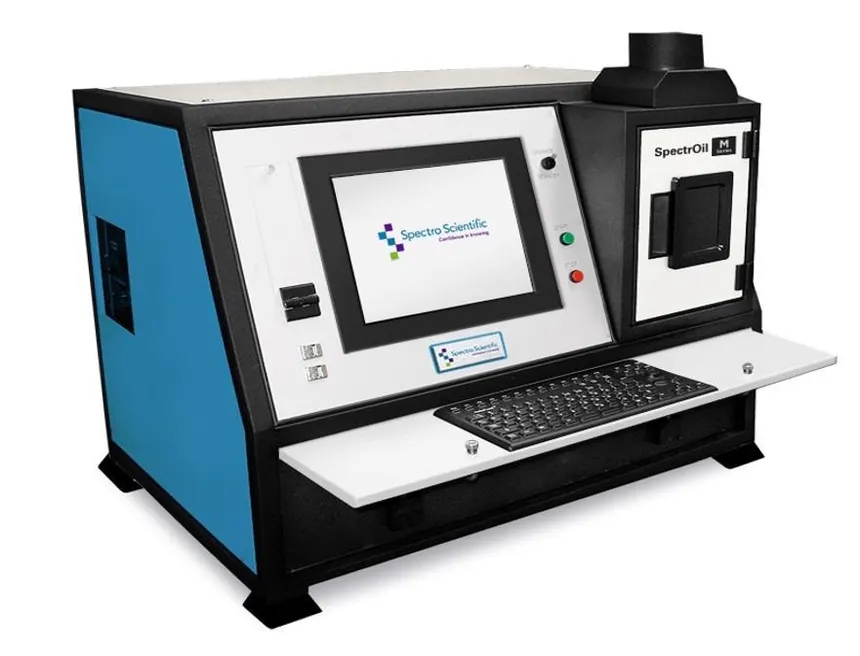

Seri SpectrOil M

SpectrOil M Series adalah spektrometer RDE-OES yang ringkas dan andal, disetujui untuk Program Anali...

Oil Analysis

Oil Analysis

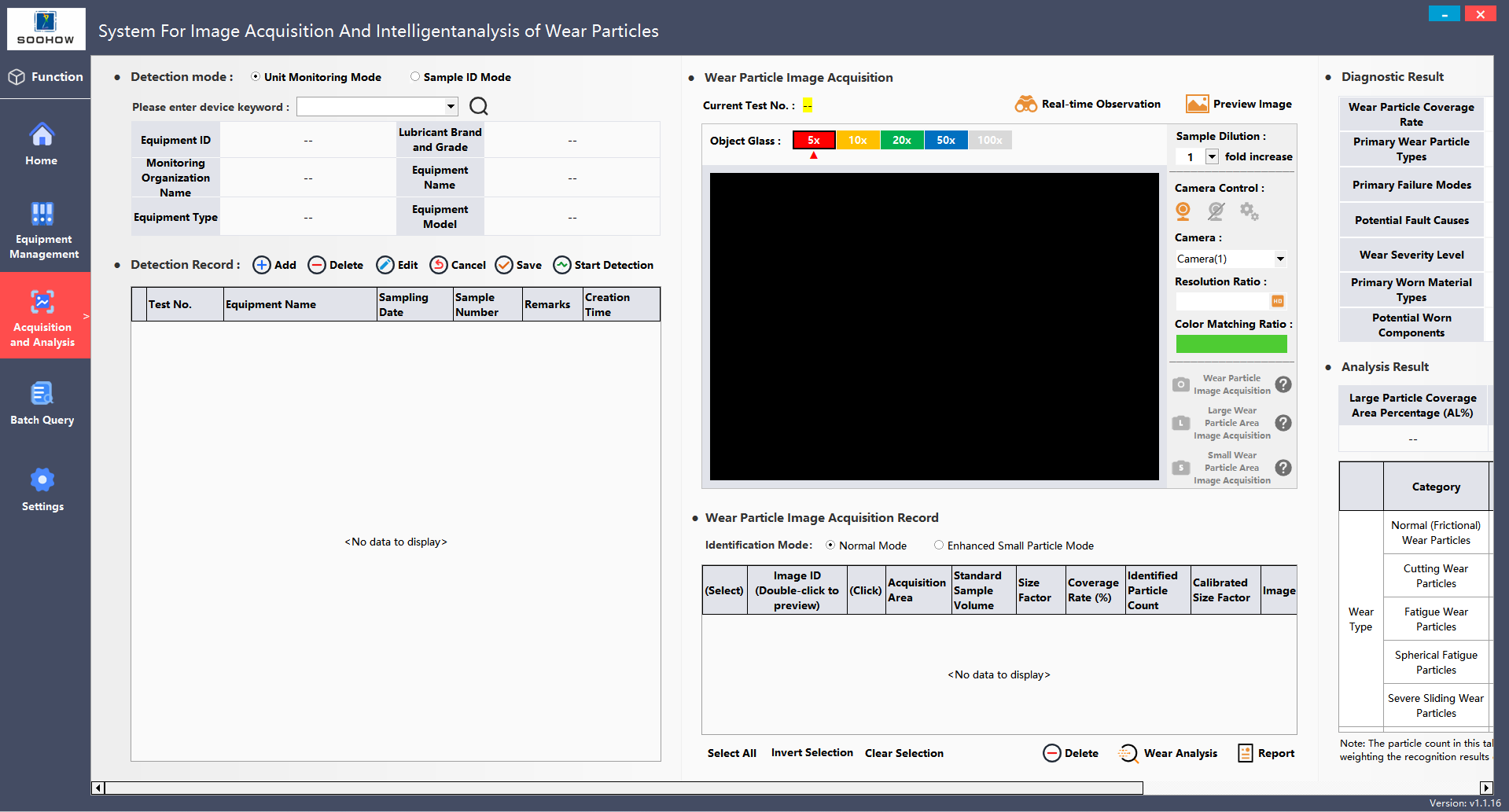

Sistem Akuisisi Gambar & Analisis Cerdas Partikel Keausan Berbasis AI

Sistem canggih ini adalah solusi mutakhir untuk Ferografi modern dan pemantauan kondisi oli. Dengan ...

Siap Menemukan Solusi yang Tepat?

Tim kami dapat membantu Anda memilih produk yang sempurna untuk Kelautan / Maritim aplikasi