Marine

Aperçu de l'Industrie

Caractéristiques Clés

Challenges

Being at sea for long periods of time makes the use of on-shore oil analysis labs impractical for marine vessels. By the time results are received back on board the equipment being analyzed might have failed already.

offers a set of solutions to transform the vessel owner’s onboard oil analysis program. As instrumentation size decreases and becomes more portable, oil analysis devices are now being put in the hands of the end user. It has been proven that these new smaller devices do not sacrifice analytical performance. This brings the end user closer to the vessel and its problems, enabling time-sensitive, critical decision making.

Cold Corrosion - Large, two-stroke diesel engines are used in over 30,000 ships worldwide. Due to over lubrication, they waste in excess of US$2 billion of cylinder oil every year. This creates more than 1.25 million tons of contaminated drain oil that needs proper disposal. This over-lubrication in slow speed, two-stroke marine diesel engines can cost ship managers and owners more than $100,000 per year per ship.

Cylinder under-lubrication leads to cold corrosion and early failure of expensive engine components like pistons, piston rings and cylinder liners. Careful monitoring of cylinder oil BN allows the operator to use enough oil to prevent cold corrosion without wasting valuable oil and additives.

Tests et Applications Typiques

Wear

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Chemistry

Total Base Number (TBN) - TBN measures the amount of active additive left in a sample of oil. The TBN is useful for people who want to extend their oil usage far beyond the normal range. The TBN of a used oil can aid the user in determining how much reserve additive the oil has left to neutralize acids. The lower the TBN reading, the less active additive the oil has left.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Oxidation, Nitration, Sulfation - Lubricating oil at elevated temperatures can react with oxygen and nitrogen in the atmosphere, as well as sulfur in fuel, to form undesirable by-products that can affect the oil's viscosity and lead to corrosion or damage of equipment.

Contamination

Fuel Dilution - Fuel dilution in oil is a condition caused by excess, unburned fuel mixing with engine oil in an engine crankcase. Hydrocarbon-based fuel, usually with a lower vapor pressure than the lubricant, has a thinning effect, lowering the oil viscosity. Oil film strength is reduced, increasing the cylinder liner and bearing wear.

Glycol - Glycol is found in engine coolant. If glycol is found in engine oil it typically indicates there is a leak in the engine that can cause catastrophic damage to the cylinder or cylinder wall.

Water - Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

Ressources de l'Industrie

Pas de Ressources Disponibles

Nous mettons à jour notre bibliothèque de ressources pour cette industrie. Revenez bientôt ou contactez-nous pour demander une documentation spécifique.

Demander une DocumentationProduits de Support

Oil Analysis

Oil Analysis

Aquamax KF PRO GPL

L’Aquamax KF PRO LPG est un titrateur Karl Fischer coulométrique spécialisé pour détermi...

Oil Analysis

Oil Analysis

Ferrographe à lecture directe DR100

Le DR100 est un ferrographe de paillasse qui offre une quantification rapide et automatisée des par...

Oil Analysis

Oil Analysis

Série FluidScan® 1000

Le FluidScan est un spectromètre infrarouge portable utilisé pour l’analyse de l’état des hui...

Oil Analysis

Oil Analysis

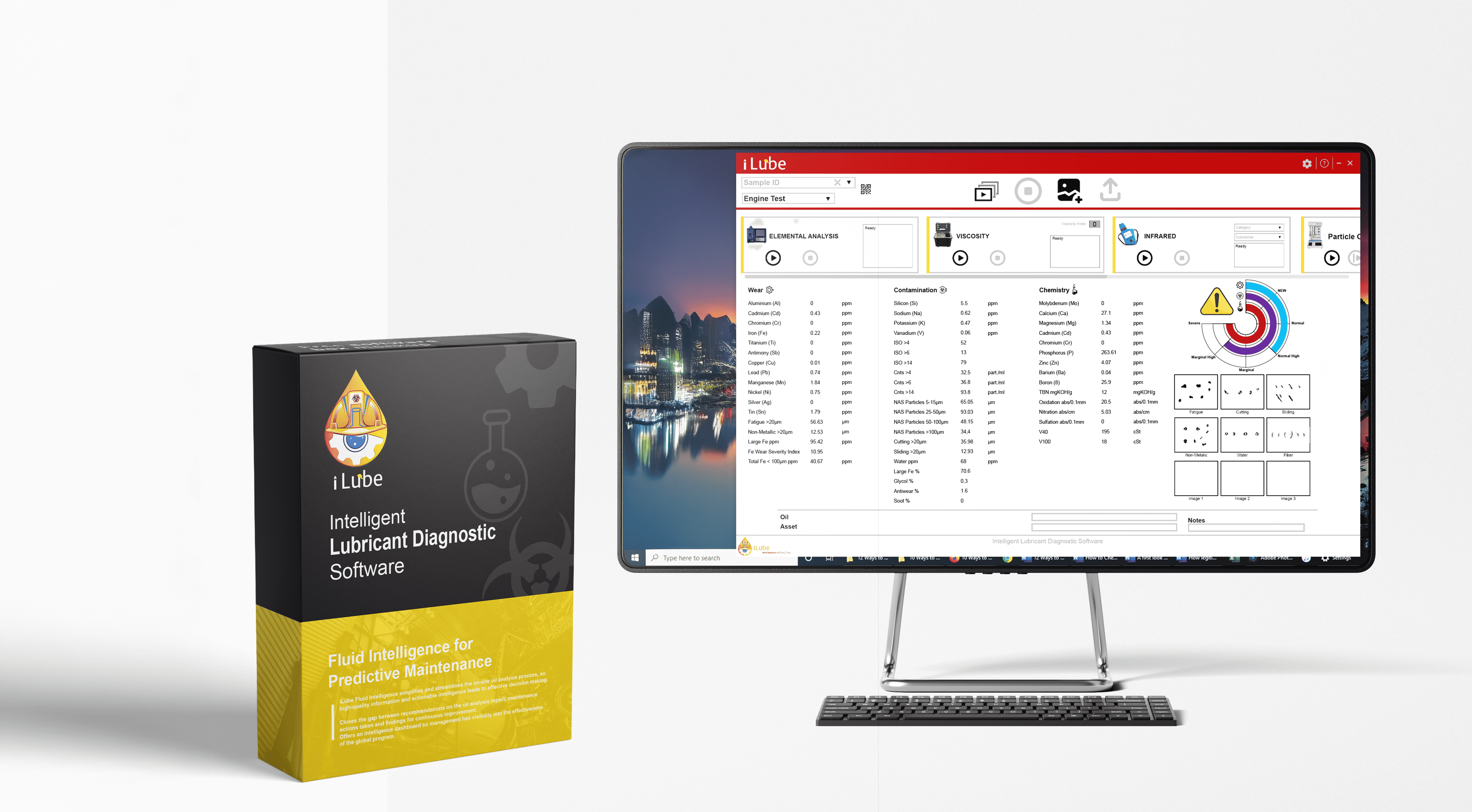

iLube – Diagnostic intelligent de lubrifiant

iLube est une plateforme logicielle intelligente, flexible et multilingue d’analyse d’huile con�...

Oil Analysis

Oil Analysis

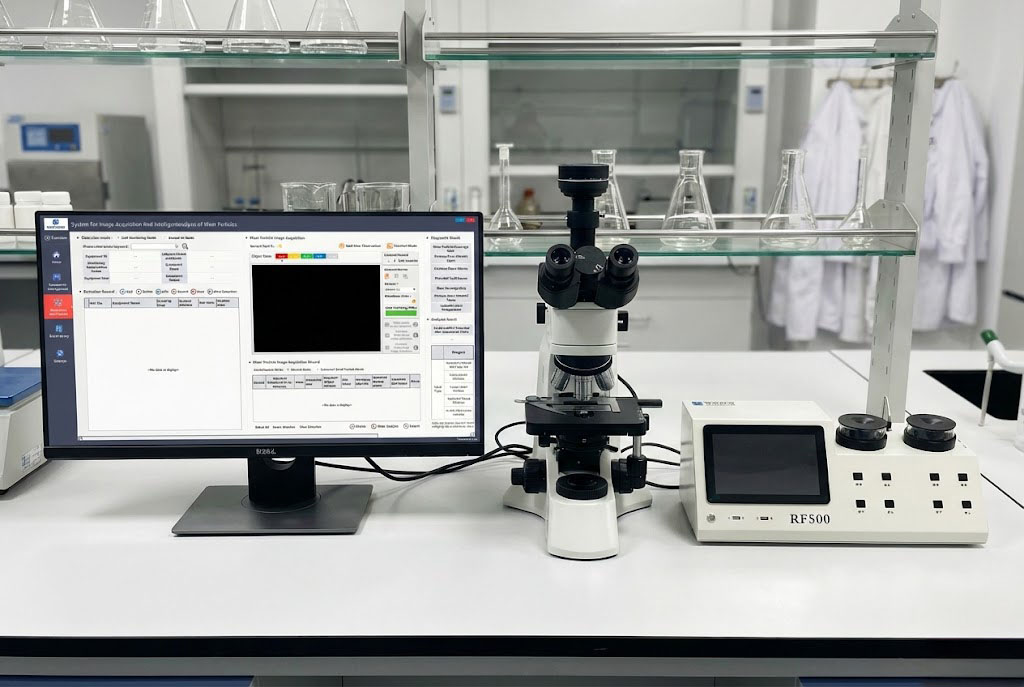

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

Analyseur intelligent d’huile IOA8000

L’IOA8000 est un analyseur portable et convivial de fluorescence X dispersive en énergie (EDXRF),...

Oil Analysis

Oil Analysis

Testeur de rigidité diélectrique d’huile isolante JKJQ‑1A

Le JKJQ‑1A est un testeur portable entièrement automatique à une seule coupelle conçu pour mesu...

Oil Analysis

Oil Analysis

Série LaserNet 200

La série LaserNet 200 est un système avancé et automatisé d’analyse des particules conçu pour...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

MBP – Tensiomètre à pression de bulle

Le MBP 200 de DataPhysics Instruments utilise la méthode de pression maximale de bulle pour mesur...

Oil Analysis

Oil Analysis

Série MicroLab

La série MicroLab de Spectro Scientific est un système automatisé complet d’analyse d’huile s...

Oil Analysis

Oil Analysis

MiniVisc 3000

Le MiniVisc 3000 est un viscosimètre cinématique portable révolutionnaire qui fournit des mesures...

Oil Analysis

Oil Analysis

Pi Raptor Portable

Le Raptor Portable Dry Powder Particle Size & Shape Analyzer est le premier système véritablement ...

Oil Analysis

Oil Analysis

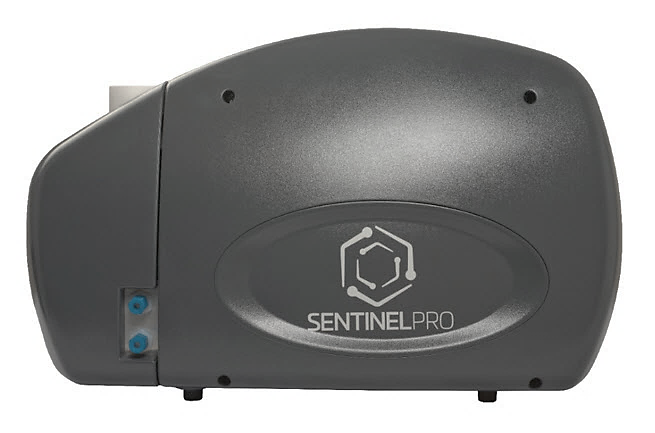

Pi Sentinel PRO

Le SentinelPro est un analyseur d’images dynamiques haute performance conçu pour les applications...

Oil Analysis

Oil Analysis

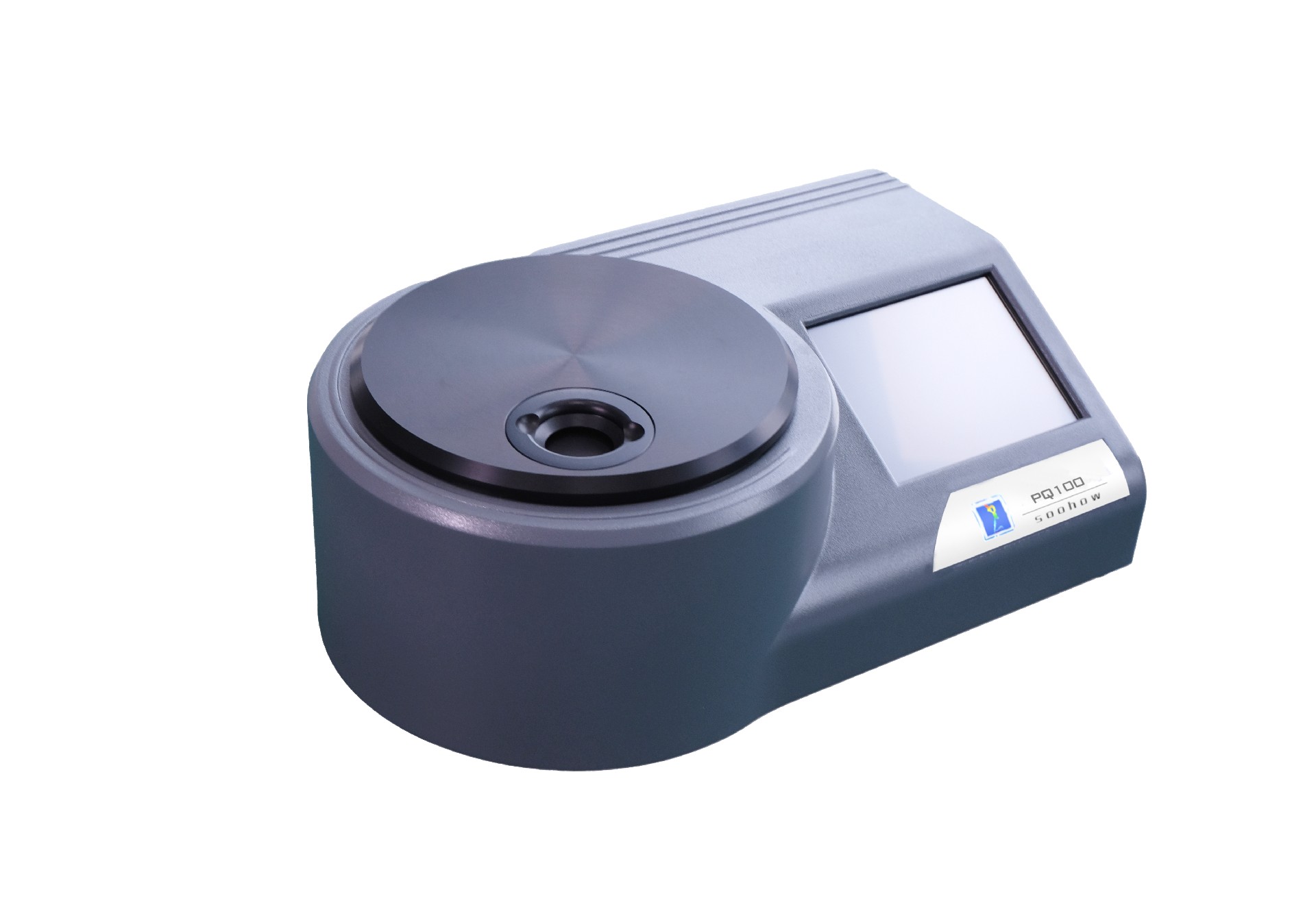

Analyseur d’usure ferromagnétique PQL PQ100

Le PQ100 est un appareil compact et portable conçu pour la détection rapide et la quantification d...

Oil Analysis

Oil Analysis

RotrOil

Le RotrOil est le spectromètre d’émission optique à électrode à disque rotatif (RDE-OES) de d...

Oil Analysis

Oil Analysis

Smart Lu C

Le Smart Lu C est un système MiniLab compact et prêt pour le terrain combinant trois outils de...

Oil Analysis

Oil Analysis

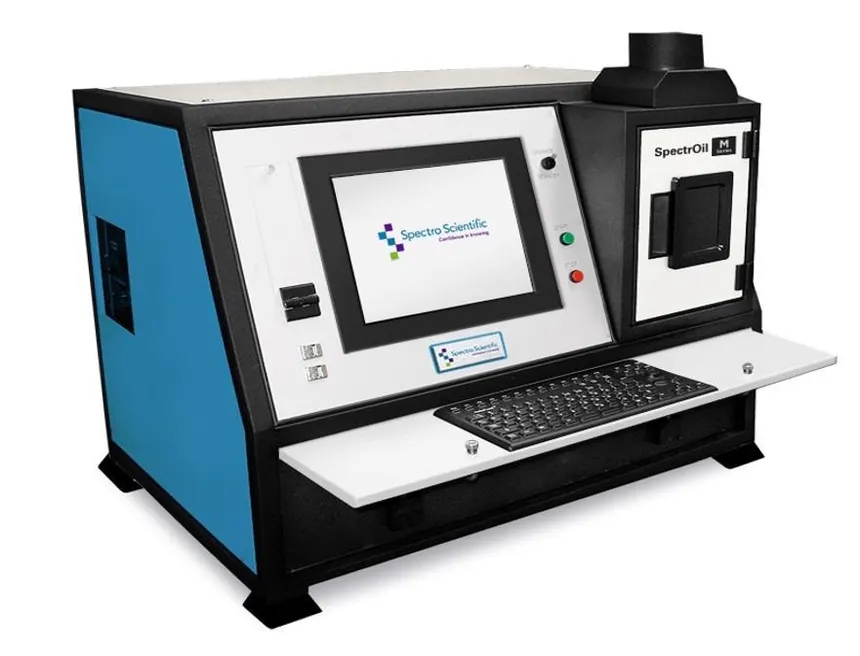

Série SpectrOil M

La série SpectrOil M est un spectromètre d’émission optique à électrode à disque rotatif (RD...

Oil Analysis

Oil Analysis

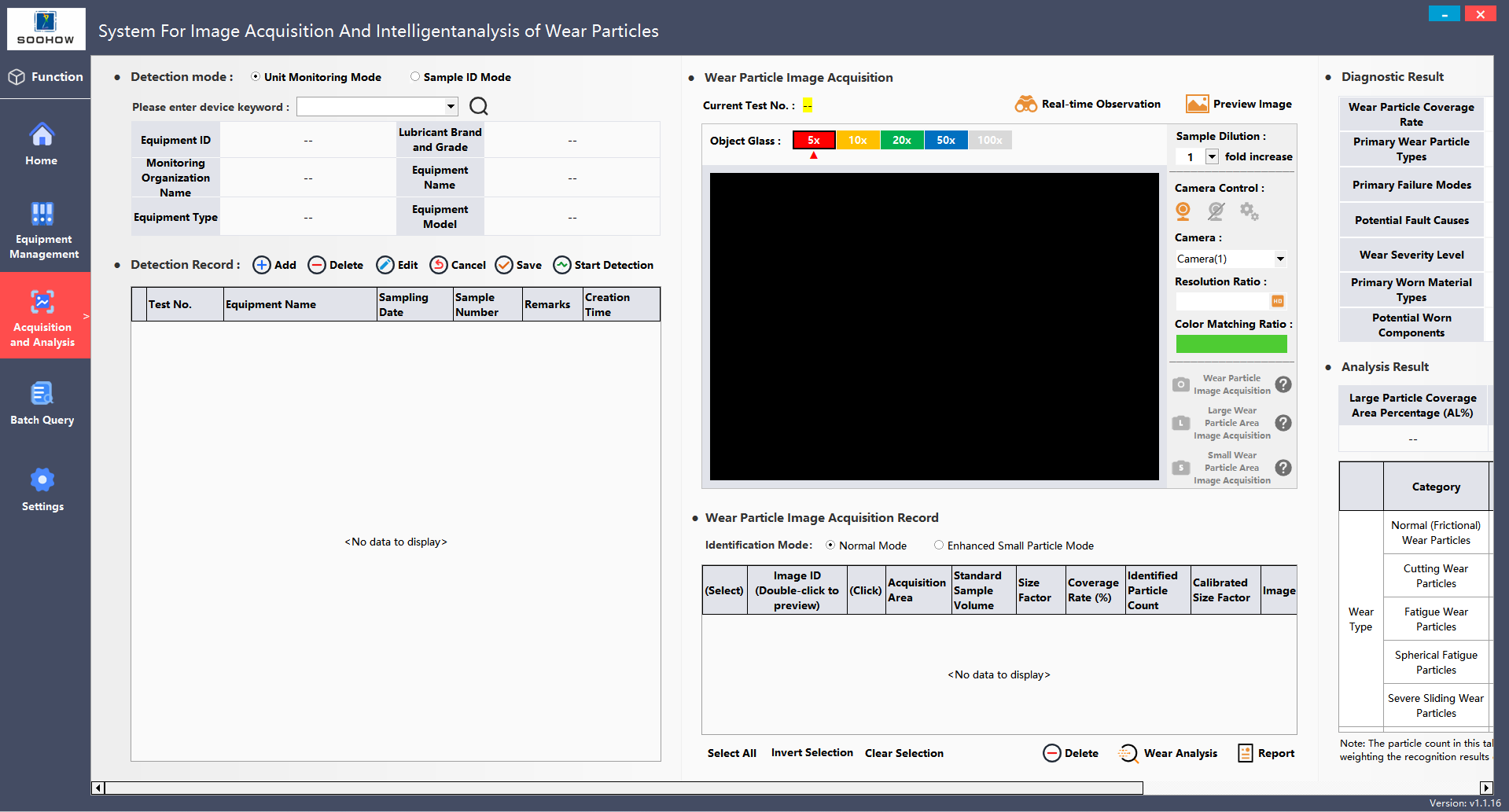

Système d'Acquisition d'Images et d'Analyse Intelligente des Particules d'Usure (Propulsé par l'IA)

Description du Produit Ce système avancé est une solution de pointe pour la ferrographie moderne e...

Prêt à Trouver la Bonne Solution?

Notre équipe peut vous aider à sélectionner les produits parfaits pour vos Marine applications