Stand Alone Instruments: A Comprehensive Guide

When it comes to analyzing the properties of fluids, Stand Alone Instruments are the go-to equipment for many industries. These instruments offer reliable and precise measurements of various parameters that help in understanding the physical and chemical properties of fluids. Here are some of the popular Stand Alone Instruments and their applications:

Viscosity Measurement

Viscosity is a crucial parameter in determining the performance of lubricants, oils, and other fluids. The S-flow IV⁺ Kinematic Viscometer and S-flow Houillon viscometer are popular instruments used for measuring viscosity. The AUTOMATIC VISCOMETER WASHER is another useful instrument that helps in cleaning the viscometers after use.

The latest generation of the new S-flow is the Houillon viscometer which builds on the solid foundation of its predecessors, like the U-Visc, to offer the ultimate in automatic viscosity testing of Newtonian samples, such as petroleum products. The S-flow IV+ offers all the tried and tested advantages of a Houillon-type tube design such as short process times, small sample volume, and low solvent consumption, but this Houillon viscometer now also includes an optional autosampler to allow for fully unattended operation. All of this is controlled from a central user interface that takes care of result storage, autosampler control, VI calculations, and much more. This Houillon viscometer complies fully with ASTM D7279. It is the ideal system for used oil analysis labs that need to test a wide range of lubricant viscosities. Tell us more about the required specifications to receive a tailor-made viscometer system. Kinematic viscometry system for petroleum products The VTW Classic is an apparatus designed for the external and internal washing of all current types of viscometer tubes. The viscometer tubes are suspended in solvent vapors at 80°C, allowing for very fast cleaning of up to 6 tubes in just 5 to 15 minutes, with negligible solvent consumption. This ensures efficient and reliable cleaning for a range of viscosity measurement applications.

S-flow IV⁺ Kinematic Viscometer

S-flow Houillon viscometer

AUTOMATIC VISCOMETER WASHER

Elemental Analysis Instruments

Elemental analysis instruments are used to detect and quantify the elemental composition of fluids. The SpectrOil 120 Series - (RDE-OES) Elemental Analyzer, SpectrOil M Series, and SpectrOil M: JOAP Certified Elemental Analyzer are some of the popular instruments in this category. They help in identifying the presence of trace metals and other contaminants in fluids.

The SpectrOil 100 Rotating Disc Electrode Optical Emission Spectrometer (RDE-OES) is a reliable and precise means of determining elemental composition in various fluids, including lubricating oil, coolant, light or heavy fuels, grease, and process water. It is widely used in commercial oil laboratories, on-site or trailer labs, and supports the Joint Oil Analysis Program (JOAP) calibration with results that correlate to those from the SpectrOil MNW, the only approved spectrometer for elemental analysis of lubricating oil for US and NATO military use.

The SpectrOil RDE-OES consists of three main components: an Excitation Source, an Optical System, and a Readout System. It uses a specific calibration program to eliminate the matrix effect, which enables switching from oil to fuel to coolant or water in just seconds. The SpectrOil 100 Series is a compact, rugged, and transportable optical spectrometer for elemental analysis in oil and fuel. Meets military shock and vibration and environmental test standards, making it ideal for remote locations. Requires no sample preparation and has a 30-second analysis time. Features a specific calibration program that eliminates the matrix effect for compliance with ASTM standards. Switching from oil to fuel to coolant or water only takes seconds, not hours like ICP and other instruments. RDE-OES consists of an excitation source, optical system, and readout system for accurate and sensitive measurements. Self-sustained with built-in industrial touch panel PC and requires only AC power. Sub ppm LOD for most critical elements and less than 100 ppb LOD for V and alkali metals for SpectrOil M/F-LD. Compliant to ASTM D6728. The AMETEK Spectro Scientific oil analysis spectrometer is a compact, rugged, and transportable tool for rapidly analyzing in-service oils for wear metals, contaminants, and additives. It is the only approved oil analysis spectrometer in the US Department of Defense Joint Oil Analysis Program, and it is the industry standard for the Air Force, Navy, Army, and Marines. The spectrometer uses the rotating disc electrode technique to measure quantities of dissolved and suspended fine particles in natural or synthetic petroleum-based products and coolants. It has a 30-second analysis time and can analyze up to 31 elements simultaneously. It does not require special training or utilities and is compliant with ASTM standards. The spectrometer has specific calibration programs for different fluids and is manufactured by AMETEK Spectro Scientific. This tool is used for in-line analysis of fuel for large diesel engines on board ships and power plants. It measures the concentration of wear metals, contaminants, and additives in fuel. The tool uses laser-induced breakdown spectroscopy (LIBS) technology for fast and accurate analysis. It is compact, lightweight, and easy to install, and it is self-contained with no need for external cooling or vacuum systems. It provides results in less than 60 seconds and has a wide range of elements it can detect. It is compliant to ASTM D8150.SpectrOil 120 Series - (RDE-OES) Elemental Analyzer

SpectrOil M Series

The SpectrOil 100 Series

SpectrOil M: JOAP Certified Elemental Analyzer

Rapid Oil Analysis with AMETEK Spectro Scientific

SpectrOil M - SpectrOil M/F-W Fuel Analyzer

In-Line Fuel Analysis with LIBS Technology

Wear Particles and Cleanness

LaserNet 200 Series and T2FM 500 - Laboratory Ferrography are commonly used instruments for detecting wear particles and analyzing the cleanness of fluids. These instruments help in identifying the source of wear particles and help in predicting the remaining useful life of the equipment.

The LaserNet 200 Series is a particle counter and wear particle analyzer used for contamination control and predictive maintenance in commercial laboratories and industrial plants. It includes the following specifications:

The T2FM 500 Ferrography Laboratory is a device used for predictive maintenance by analyzing wear and contaminant particles in lubrication oils, hydraulic fluids, greases, coolants, and fuels. It has the following features: The T2FM 500 Ferrography Laboratory uses a glass thistle tube to provide a constant and efficient flow of sample onto the ferrogram, achieving efficient separation of particles up to 800 μm in size. It is also compliant with ASTM D7690 standards. The device is easy to operate and can help prevent costly machinery failures by identifying potential issues before they become major problems.LaserNet 200 Series

LaserNet 200 Series

T2FM 500 - Laboratory Ferrography

T2FM 500 Ferrography Laboratory

Physical Properties and Contamination by IR

FluidScan® 1000 Series - Handheld Infrared Oil Analyzer is a portable instrument that measures the physical properties and contamination of fluids using infrared technology. This instrument helps in detecting contaminants, degradation, and other irregularities in the fluid.

FluidScan® 1000 Series - Handheld Infrared Oil Analyzer

Dedicated Direct Infrared Spectrometer for Lubricant Condition Monitoring

Fuel Dilution and Flash Point

The FDM 6000 - Portable Fuel Dilution Meter is an instrument used for measuring the dilution of fuel in oils. It helps in detecting fuel leakage and contamination in the oil. Additionally, it measures the flash point of the fluid, which is a critical safety parameter.

The FDM 6000 is a portable fuel dilution meter designed to measure the concentration of fuel in lubricants with a range of 0.2 to 15%. The meter conforms to ASTM D8004 - "Standard Test Method for Fuel Dilution of In-Service Lubricants Using Surface Acoustic Wave Sensing" and provides direct fuel dilution measurements for quick and accurate results. The FDM 6000 uses an innovative headspace sampling fang design to ensure excellent repeatability with a coefficient of variation of less than 5%. It also utilizes disposable FDM vials to eliminate carryover contamination and reduce the risk of measurement errors. The meter requires only 0.5ml of oil for testing, making it ideal for field use applications.FDM 6000 - Portable Fuel Dilution Meter

FDM 6000 - Portable Fuel Dilution Meter

Gases in Oils

The Gas Extractor - Gases in oils is a popular instrument used for detecting gases in oils. This instrument helps in identifying the presence of gases such as oxygen, nitrogen, and methane, which can indicate the state of the fluid and its potential for causing damage.

The T2FM 500 Ferrography Laboratory is a device used for predictive maintenance by analyzing wear and contaminant particles in various industrial fluids such as lubrication oils, hydraulic fluids, greases, coolants, and fuels. The device helps in determining the wear modes inside a machine and provides maintenance recommendations. The device separates and concentrates the particles in a sample using a glass thistle tube. The sample is passed through a magnetized wire, which attracts the ferrous wear particles, and a constant and efficient flow of sample onto the ferrogram is provided to achieve efficient separation of particles up to 800 μm in size. The T2FM 500 Ferrography Laboratory is compliant with ASTM D7690 standards. It is easy to operate and requires minimal training to get started with. With its efficient particle separation and microscopic examination capabilities, it helps in identifying and analyzing wear modes in a machine, and provides recommendations for maintenance and prevention of breakdowns. The T2FM 500 Ferrography Laboratory is an efficient and reliable device for analyzing wear and contaminant particles in industrial fluids. Its ability to separate and concentrate particles, and provide recommendations for maintenance and prevention, makes it an essential tool for predictive maintenance in various industries.Gas Extractor - Gases in oils

T2FM 500 Ferrography Laboratory Device

Working Principle

Compliance and Ease of Use

Applications

Conclusion

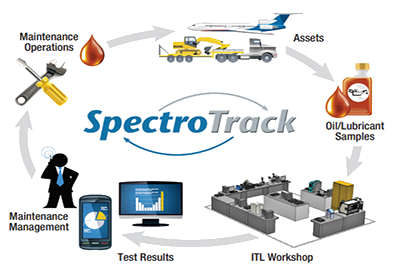

SpectroTrack

SpectroTrack - Fluid Analysis Information Management System is a software platform that helps in managing fluid analysis data. It helps in tracking fluid analysis results, creating reports, and managing inventory. This instrument offers a centralized and streamlined approach to fluid analysis management.

SpectroTrack is an information management system (IMS) designed to streamline and optimize oil analysis programs for machine condition monitoring. It provides a single, end-to-end view of a sample lifecycle from sample submission to results entry and all trending, imaging, numerical, and textual asset data in one secure location. SpectroTrack is optimized for oil analysis programs and can be used for both dedicated and contract testing. It provides critical information for assessing machine condition and streamlines the workflow between equipment maintainers and testing labs. With automatic data collection from Spectro instruments and multi-lab support, SpectroTrack is a valuable tool for research and industrial applications. SpectroTrack

SpectroTrack: Optimized Information Management System for Machine Condition Monitoring

Titration

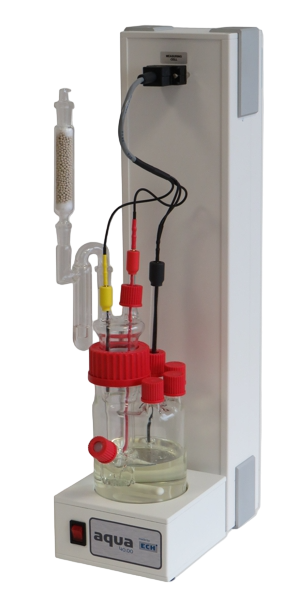

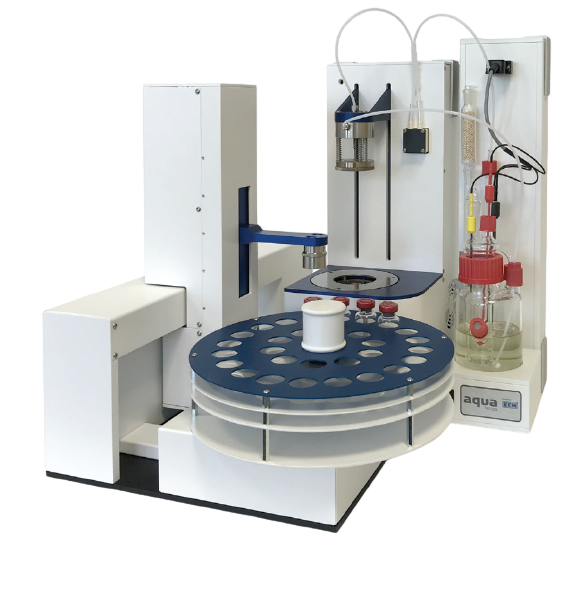

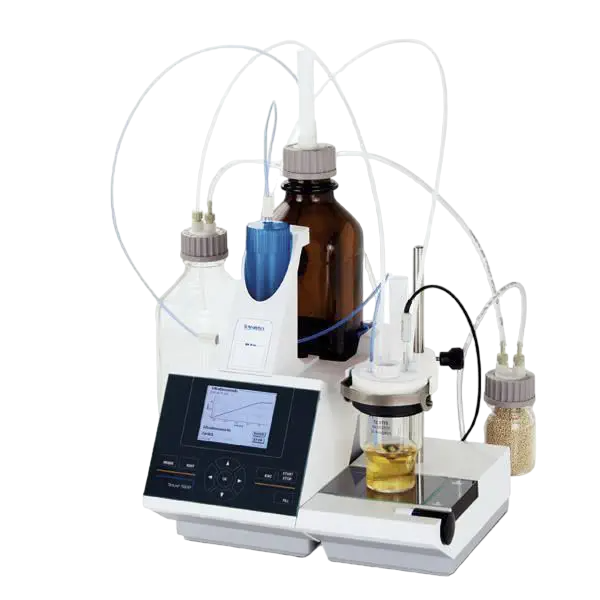

Titration instruments such as Aquamax KF Plus - ASTM D6304, Aquamax KF PRO Oil, AQUA 40.00 - Basic Module, AQUA 40.00 - Vario Headspace Module, Volumetric KF Titrator, and TAN/TBN Titrator are widely used for determining the water content and TAN/TBN values in fluids. These instruments offer accurate and reliable results, making them a popular choice for fluid analysis.

In conclusion, Stand Alone Instruments play a vital role in fluid analysis. They offer reliable and precise measurements of various parameters that help in understanding the physical and chemical properties of fluids. With a wide range of instruments available, choosing the right one for your application is crucial. Contact us to learn more about these instruments and how they can benefit your industry.

The Aquamax KF Plus is a coulometric Karl Fischer titrator used for determining water content in various substances. It is a reliable and accurate instrument that comes with several features, including: The Aquamax KF PRO Oil is a coulometric Karl Fischer titrator designed for determining water content in petroleum products, lubricating oils, and additives. It is equipped with a temperature ramping program that separates free and chemically bonded water, ensuring high accuracy results. The device also features a closed-loop carrier gas circulation system that minimizes interference side reactions caused by additives or sulfur/mercaptans. The AQUA 40.00 Basic Module is a device used for water determination in liquids and gases. It features user-friendly handling, fast and reproducible analyses, and can be used with all common Karl Fischer reagents. The AQUA 40.00 Basic Module can be expanded to the AQUA 40.00 Vario for water determination in all sample types using headspace technology. Additional modules are also available for different sample types. The AQUA 40.00 with Vario Head Space Module is a device used for analysis without sample preparation. It has a measuring range of 1 g - 100 mg and a resolution of 0.1 μg. The device has a reproducibility of 3 μg for 10...1000 μg and 3% for > 1 mg. It can operate in a temperature range of 35 °C to 300 °C and has a power input of 250 W. The device comes in two versions: The AQUA 40.00 with Vario Head Space Module is manufactured by ECH Elektrochemie Halle GmbH in Germany and is suitable for use in the laboratory, mobile, on-line, and process applications. Karl Fischer (KF) titration, as well as the reagents and equipment needed for the procedure. However, it does not specifically mention the Volumetric KF Titrator. A Volumetric KF Titrator is a type of titration instrument used for determining the water content in a sample. It works by adding a known amount of KF reagent to the sample, which reacts with any water present. The amount of KF reagent needed to fully react with the water is then measured, and the water content of the sample can be calculated. Volumetric KF Titrators typically consist of: the Titramax VT TAN/TBN, an automatic volumetric titrator used for the determination of TAN/TBN value in oil samples.Aquamax KF Plus - ASTM D6304 in-lab and on-site water determination

Aquamax KF Plus: A Coulometric Karl Fischer Titrator

Aquamax KF PRO Oil- Water Determination in Oil Samples

Aquamax KF PRO Oil

Features

AQUA 40.00 - Basic Module

AQUA 40.00 Basic Module for Water Determination

Features

AQUA 40.00 Vario

Technical Specifications

AQUA 40.00 - Vario Headspace Module

AQUA 40.00 with Vario Head Space Module

Volumetric KF Titrator

Volumetric KF Titrator

TAN/TBN Titrator

Technical Specifications of Titramax VT TAN/TBN Volumetric Titrator

Surface Tension

Surface tension is a physical phenomenon that describes the cohesive forces between the molecules at the surface of a liquid. It is measured in units of force per unit length and is influenced by various factors such as temperature, pressure, and the nature of the liquid.

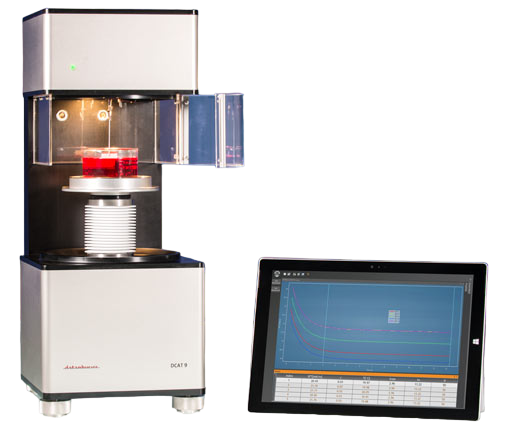

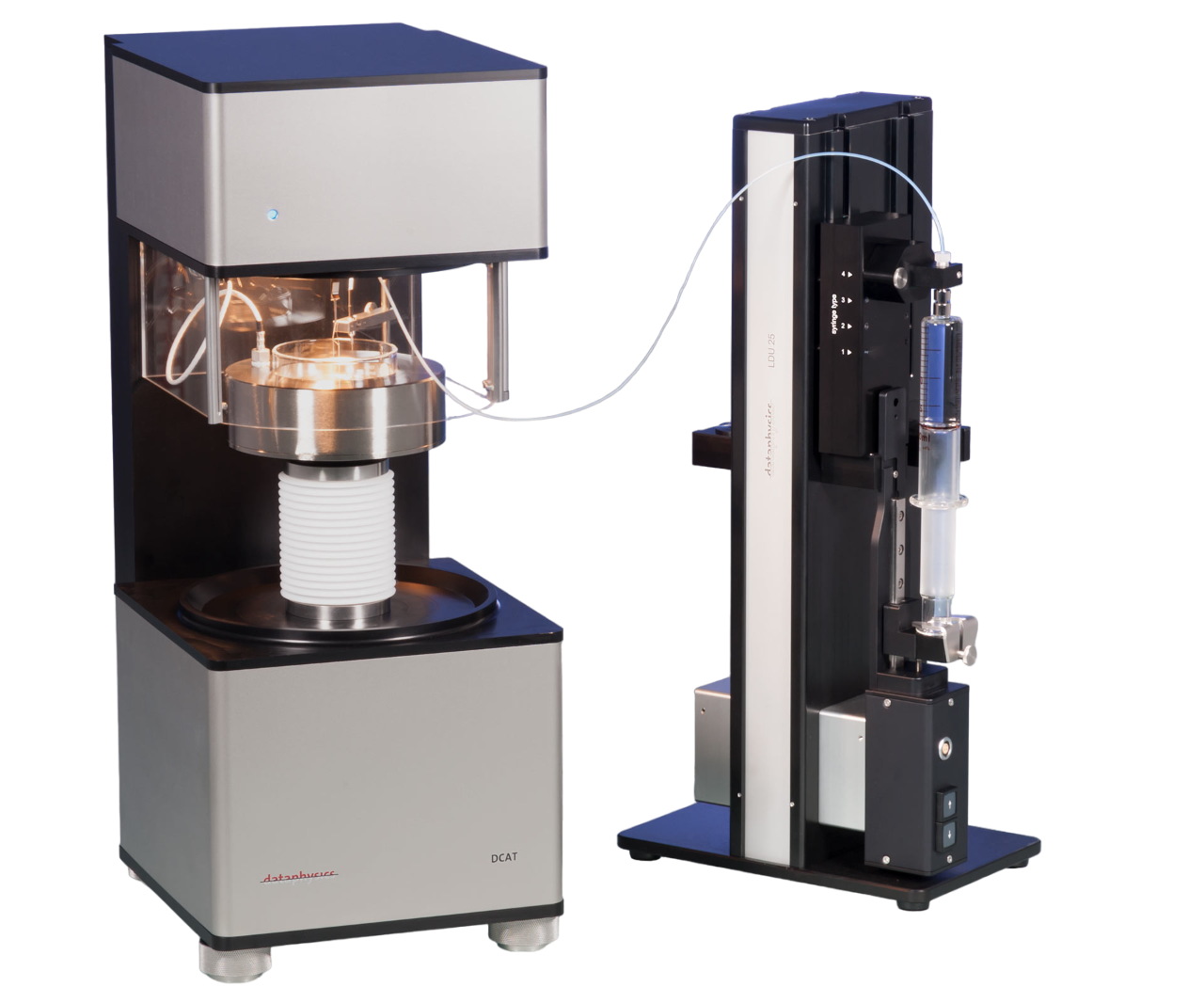

DCAT 8 & 9 are weight-based measuring instruments used for determining the surface and interfacial tension and the density of liquids and solids. DCAT 15 is a versatile instrument used for determining the surface and interfacial tension, surface energy of solids, and sedimentation and penetration properties of liquids and solids. It offers additional measuring methods compared to other DCAT models, such as dynamic contact angle determination and automated critical micelle concentration (CMC) determination using a liquid dosing unit. The DCAT 15 can be extended with a liquid dosing unit LDU 25 to create sequential concentration series of surfactant solutions. It features an integrated digital thermometer and a liquid temperature control unit TV 70 for measuring temperature-dependent properties. The weighing range for DCAT 15 is 10 μg to 210 g, and the measuring value rate is up to 100 values/s. This instrument offers fast and precise actuation, automatic crash protection, and intuitive operation via the TP 50 control panel. The DCAT 25 is a weight-based measuring instrument that offers a highly precise weighing system with a resolution of 0.1 μg, making it suitable for measuring even on single fibers. It is used for determining the surface and interfacial tension, the surface energy of solids, and the adhesion properties of liquids and solids. The DCAT 25SF is a weight-based measuring instrument used for determining the surface and interfacial tension, the surface energy of solids, and the adhesion properties of liquids and solids. It is highly precise, with a resolution of 0.1 μg, making it suitable for measuring even on single fibers. DCAT 8 & 9

DCAT 8 & 9 Measuring Instruments

DCAT 15

DCAT 15 Weight-based Measuring Instrument

DCAT 25

DCAT 25: A Versatile Weight-Based Measuring Instrument

Features

DCAT 25SF

DCAT 25SF Measuring Instrument

Features