Highlights

Principle of measurement

- Evacuation of the degassing vessel

- Automatic dosing of the oil sample

- Determination of the pressure increasing for calculating the total gas content

- Separation of the extracted gas via vacuum pump

- Automatic transfer of the gas sample into the gaschromatograph

- Removal of oil sample after analysis by rinsing with inert gas

Extension modules

|

|

|

||

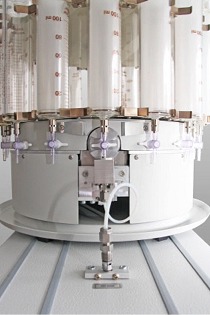

| Linking of the GasExtractor with the gas chromatograph by the TOP TOGA GC | Autosampler for automatic oil dosing | Automatic oil degassing in the OnlineDGA on basis of the GasExtractor |

Advantages

- Complete measuring device for vacuum degassing

- Extraction of gases from oils according to international standard regulations

- Working without mercury

- Fast determination of the total gas content

- Suitable for linking with a gas-phase chromatograph

- Basis for quantitative determination of the dissolved gases

- Powerful four stage membrane pump

- Digital pressure measurement

- Valve for automatic oil feed and drain

- Automatic procedure with vacuum-tight solenoid valves and fittings

- Uncontaminated degassing and transfer to gas chromatograph

- Completed data acquisition- and date evaluation system