Municipalities

Aperçu de l'Industrie

Caractéristiques Clés

Sending oil samples to an outside laboratory works but it can be expensive and results can take days or weeks. Waiting for results means the vehicle might be back on the road and failures could happen before the analysis is obtained.

Having on-site oil analysis capability can help fleet managers solve issues while the vehicle is still in the garage. It also helps them achieve operational cost savings, reduce downtime and unexpected failures as well as manage the work flow of the service bays. Many cities and towns also use oil analysis to help achieve “green fleet” initiatives by monitoring the condition of the oil and changing only when necessary rather than on a time or mileage basis.

Challenges

Oil drains are expensive for large vehicles

By monitoring oil condition with on-site analysis the maintenance staff can determine if the oil drain interval can be extended safely. Reducing the number of oil drains required per vehicle by even just one time per year can provide significant savings across a fleet of vehicles. This also helps achieve green initiatives by reducing the oil consumption and oil disposal.

Repair costs can be high

Oil analysis can help identify potential problems early – before they become catastrophic and costly repairs. On-site analysis provides the service technicians the information about the vehicle while it is still in the garage so repairs can be made immediately before it goes back out on the road. Early identification could mean the difference between a $2,500 EGR cooler repair and a $30,000 engine rebuild.

Downtime of vehicles impacts service and revenue

When a vehicle is unavailable due to mechanical problems it means it is not available to provide necessary service like in the case of a city transit bus or if it is part of the public works fleet for things like snow removal. For companies like freight haulers or mining equipment it means it will impact the revenue generating service it provides. Oil analysis can help fleet managers to ensure their vehicles will be up and running when they are needed.

Managing maintenance work flow can be difficult

A busy service garage, especially one that maintains a large fleet of vehicles needs to optimize the flow of their vehicles to get them in, serviced and back on the road in a timely manner. Many fleet customers of the MicroLab oil analyzer will bring a vehicle in and immediately pull an oil sample for test. While it is running they can conduct other necessary service checks. Within 15minutes, they will know whether they need to change the oil or if they can move on to other tasks. Incorporating oil analysis into the routine diagnostics checks allows fleet service providers to be more efficient with their time.

Tests et Applications Typiques

Particle count- a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Chemistry

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Oxidation, Nitration, Sulfation - Lubricating oil at elevated temperatures can react with oxygen and nitrogen in the atmosphere, as well as sulfur in fuel, to form undesirable by-products that can affect the oil's viscosity and lead to corrosion or damage of equipment.

Contamination

Fuel Dilution - Fuel dilution in oil is a condition caused by excess, unburned fuel mixing with engine oil in an engine crankcase. Hydrocarbon-based fuel, usually with a lower vapor pressure than the lubricant, has a thinning effect, lowering the oil viscosity. Oil film strength is reduced, increasing the cylinder liner and bearing wear.

Soot- Soot is a product of combustion and has always been found in engine oils. Soot can use up an oil's additives and deposit on vital engine surfaces.

Glycol - Glycol is found in engine coolant. If glycol is found in engine oil it typically indicates there is a leak in the engine that can cause catastrophic damage to the cylinder or cylinder wall.

Ressources de l'Industrie

Pas de Ressources Disponibles

Nous mettons à jour notre bibliothèque de ressources pour cette industrie. Revenez bientôt ou contactez-nous pour demander une documentation spécifique.

Demander une DocumentationProduits de Support

Oil Analysis

Oil Analysis

Série FluidScan® 1000

Le FluidScan est un spectromètre infrarouge portable utilisé pour l’analyse de l’état des hui...

Oil Analysis

Oil Analysis

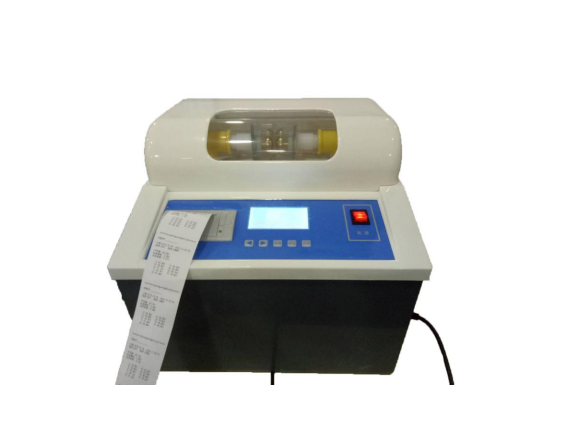

Testeur de rigidité diélectrique d’huile isolante JKJQ‑1

Le JKJQ‑1 est un testeur de rigidité diélectrique entièrement automatique conçu pour évaluer ...

Oil Analysis

Oil Analysis

Testeur de rigidité diélectrique JKJQ‑1B

Le JKJQ‑1B est un testeur de résistance diélectrique entièrement automatique à une seule coupe...

Oil Analysis

Oil Analysis

Série LaserNet 200

La série LaserNet 200 est un système avancé et automatisé d’analyse des particules conçu pour...

Oil Analysis

Oil Analysis

MiniVisc 3000

Le MiniVisc 3000 est un viscosimètre cinématique portable révolutionnaire qui fournit des mesures...

Oil Analysis

Oil Analysis

Pi Raptor Portable

Le Raptor Portable Dry Powder Particle Size & Shape Analyzer est le premier système véritablement ...

Oil Analysis

Oil Analysis

Pi Sentinel PRO

Le SentinelPro est un analyseur d’images dynamiques haute performance conçu pour les applications...

Oil Analysis

Oil Analysis

Viscosimètre cinématique portable VS800

Le viscosimètre cinématique portable VS800 est un outil de mesure de viscosité de précision, pol...

Oil Analysis

Oil Analysis

Échantillonneur de pression positive et négative PC‑VES

Le PC‑VES est un échantillonneur d’huile portable à pression positive/négative conçu pour le...

Oil Analysis

Oil Analysis

R4 RotrOil (changeur d’échantillons automatique)

Le R4 RotrOil est une version avancée et entièrement automatisée du spectromètre élémentaire R...

Oil Analysis

Oil Analysis

RotrOil

Le RotrOil est le spectromètre d’émission optique à électrode à disque rotatif (RDE-OES) de d...

Oil Analysis

Oil Analysis

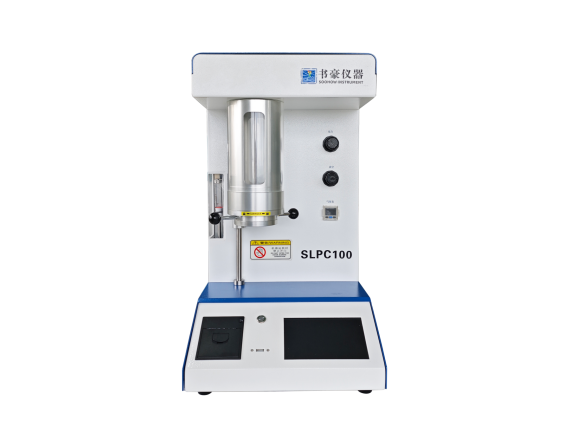

Compteur de particules d’huile de bureau SLPC100

Le SLPC100 est un compteur de particules d’huile de bureau qui utilise la méthode de comptage par...

Oil Analysis

Oil Analysis

Série SpectrOil 100

La série SpectrOil 100 est un analyseur élémentaire haute précision basé sur la technologie de ...

Oil Analysis

Oil Analysis

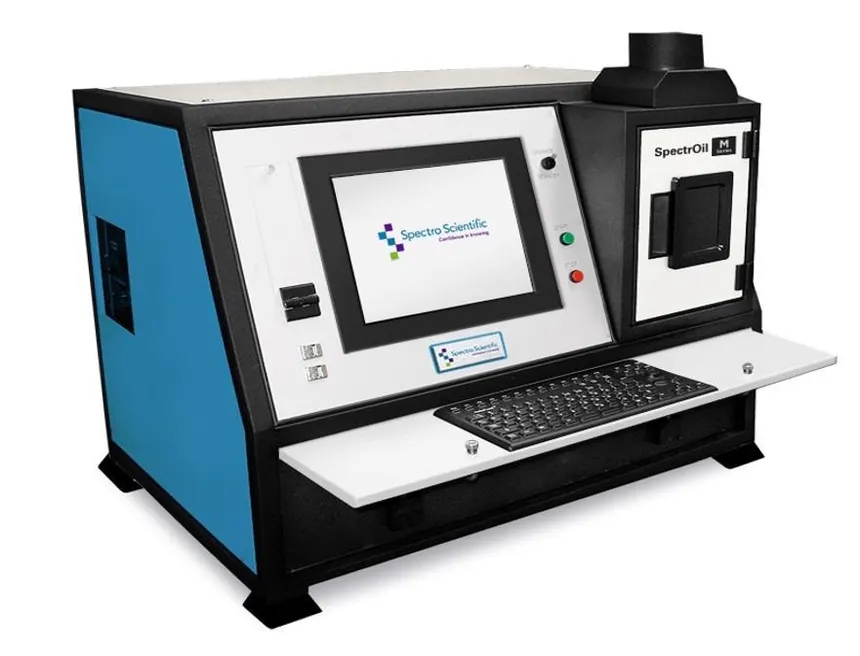

Série SpectrOil M

La série SpectrOil M est un spectromètre d’émission optique à électrode à disque rotatif (RD...

Oil Analysis

Oil Analysis

Viscosimètre portable à mouvement rapide VS600

Le viscosimètre cinématique portable VS600 est un instrument de terrain haute efficacité conçu p...

Prêt à Trouver la Bonne Solution?

Notre équipe peut vous aider à sélectionner les produits parfaits pour vos Municipalities applications