Armada Peralatan Pertambangan

Ikhtisar Industri

Fitur Utama

Challenges

Remote sites

Many sites that use off-road vehicles, like mines, are at remote locations. It can be difficult for them to rely on outside lab analysis to test their oil because it can take weeks to send samples into a lab and receive results. By the time they determine there is a problem with the vehicle, it has been returned to service and could suffer a major breakdown. Testing oil on-site allows them to make instant service decisions and keep their vehicles running.

Harsh environments

Construction and mining equipment operate in conditions that are hard on the components. Just the nature of the work they do exposes the vehicles to large amounts of contamination and debris that can cause damage especially to the hydraulics and gears which are sensitive to particulate contamination. Continually monitoring the oil condition can prevent unexpected breakdowns

Oil drains are expensive for large vehicles

By monitoring oil condition with on-site analysis the maintenance staff can determine if the oil drain interval can be extended safely. Reducing the number of oil drains required per vehicle by even just one time per year can provide significant savings across a fleet of vehicles, especially when it involves the large vehicles used in mining and constructions

Repair costs can be high

Oil analysis can help identify potential problems early – before they become catastrophic and costly repairs. On-site analysis provides the service technicians the information about the vehicle while it is still in the garage so repairs can be made immediately before it goes back out on the road. Large mining and construction equipment can be enormously expensive to repair so catching a small problem before it becomes a major issue can be a huge cost savings.

Downtime of vehicles impacts service and revenue

When a vehicle is unavailable due to mechanical problems it means it is not available to provide necessary service like in the case of a city transit bus or if it is part of the public works fleet for things like snow removal. For companies like freight haulers or mining equipment it means it will impact the revenue generating service it provides. Oil analysis can help fleet managers to ensure their vehicles will be up and running when they are needed.

Tes & Aplikasi Khas

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry

Total Acid Number (TAN)- TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Total Base Number (TBN) - TBN measures the amount of active additive left in a sample of oil. The TBN is useful for people who want to extend their oil usage far beyond the normal range. The TBN of a used oil can aid the user in determining how much reserve additive the oil has left to neutralize acids. The lower the TBN reading, the less active additive the oil has left.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Oxidation, Nitration, Sulfation - Lubricating oil at elevated temperatures can react with oxygen and nitrogen in the atmosphere, as well as sulfur in fuel, to form undesirable by-products that can affect the oil's viscosity and lead to corrosion or damage of equipment.

Contamination

Fuel Dilution- Fuel dilution in oil is a condition caused by excess, unburned fuel mixing with engine oil in an engine crankcase. Hydrocarbon-based fuel, usually with a lower vapor pressure than the lubricant, has a thinning effect, lowering the oil viscosity. Oil film strength is reduced, increasing the cylinder liner and bearing wear.

Soot - Soot is a product of combustion and has always been found in engine oils. Soot can use up an oil's additives and deposit on vital engine surfaces.

Glycol - Glycol is found in engine coolant. If glycol is found in engine oil it typically indicates there is a leak in the engine that can cause catastrophic damage to the cylinder or cylinder wall.

Water- Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

Sumber Daya Industri

Tidak Ada Sumber Daya Tersedia

Kami sedang memperbarui perpustakaan sumber daya kami untuk industri ini. Periksa kembali segera atau hubungi kami untuk meminta dokumentasi khusus.

Minta DokumentasiProduk Pendukung

Oil Analysis

Oil Analysis

Ferograf Analisis Ganda PA200

PA200 adalah ferrograf bench-top sirkuit ganda yang direkayasa untuk evaluasi kualitatif dan kuantit...

Metal Analysis

Metal Analysis

E3 Esaport

E3 Esaport adalah spektrometer emisi optik (OES) percikan/busur yang ringkas dan siap pakai di lapan...

Oil Analysis

Oil Analysis

Seri FluidScan® 1000

FluidScan adalah spektrometer inframerah genggam yang digunakan untuk analisis kondisi oli di lokasi...

Oil Analysis

Oil Analysis

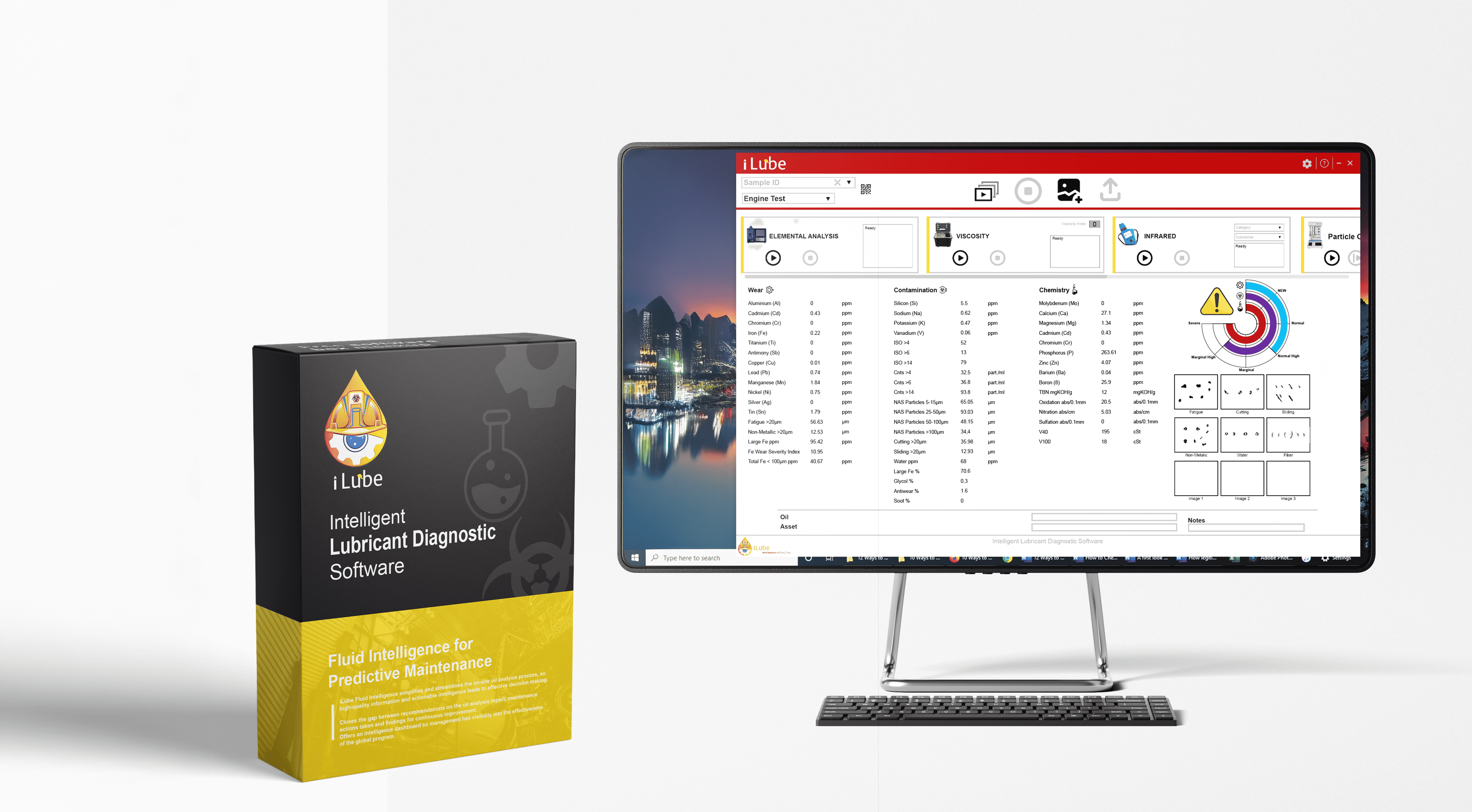

iLube – Diagnostik Pelumas Cerdas

iLube adalah platform perangkat lunak analisis oli yang cerdas, fleksibel, dan multibahasa, dirancan...

Oil Analysis

Oil Analysis

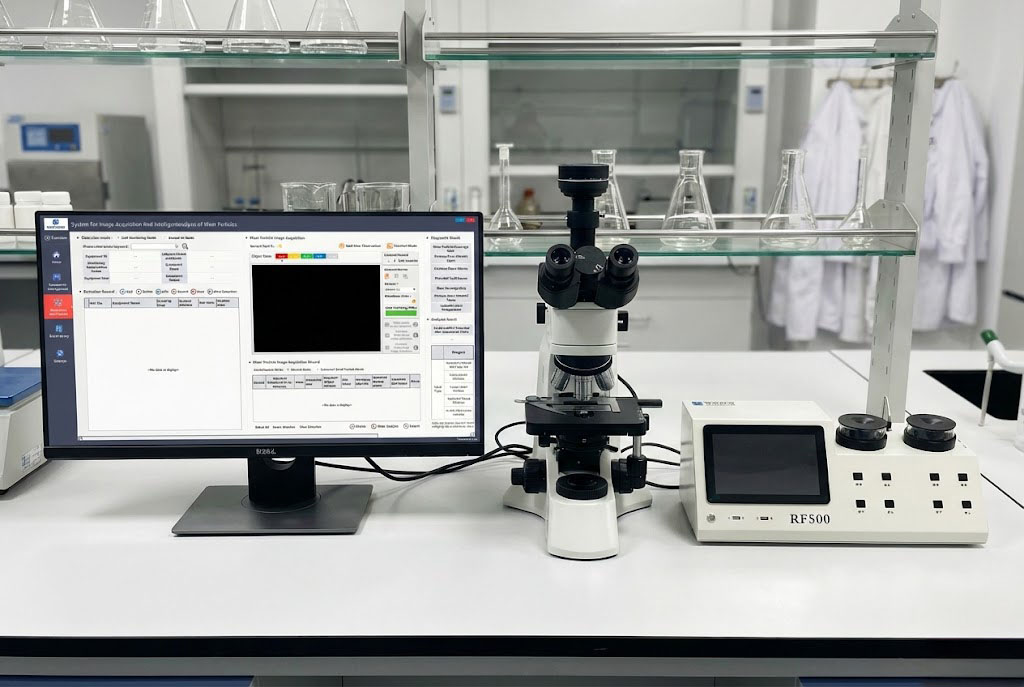

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

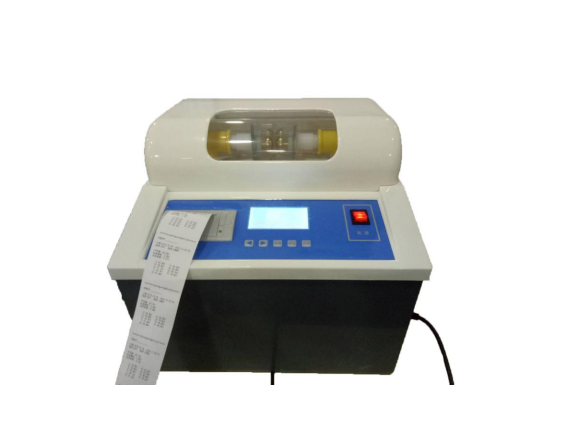

Penguji Kekuatan Dielektrik Oli Isolasi JKJQ‑1A

JKJQ-1A adalah penguji cangkir tunggal otomatis penuh yang dirancang untuk mengukur kekuatan dielekt...

Oil Analysis

Oil Analysis

Penguji Kekuatan Dielektrik JKJQ‑1B

JKJQ-1B adalah penguji kekuatan dielektrik cangkir tunggal otomatis penuh untuk oli isolasi, ideal u...

Oil Analysis

Oil Analysis

MiniVisc 3000

MiniVisc 3000 adalah viskometer kinematik portabel inovatif yang memberikan pengukuran viskositas ti...

Oil Analysis

Oil Analysis

Pi Raptor Portable

Raptor Portable Dry Powder Analyzer adalah sistem portabel pertama yang membawa analisis gambar dina...

Oil Analysis

Oil Analysis

Viskometer Kinematik Portabel VS800

VS800 Portable Kinematic Viscometer adalah alat pengukur viskositas serbaguna yang presisi, dirancan...

Oil Analysis

Oil Analysis

Pengambil Sampel Tekanan Positif dan Negatif PC‑VES

PC-VES adalah pengambil sampel oli tekanan positif/negatif portabel untuk cairan berviskositas tingg...

Metal Analysis

Metal Analysis

S9 Atlantis

S9 Atlantis adalah spektrometer emisi optik laboratorium lini teratas dari GNR, menggabungkan pengal...

Oil Analysis

Oil Analysis

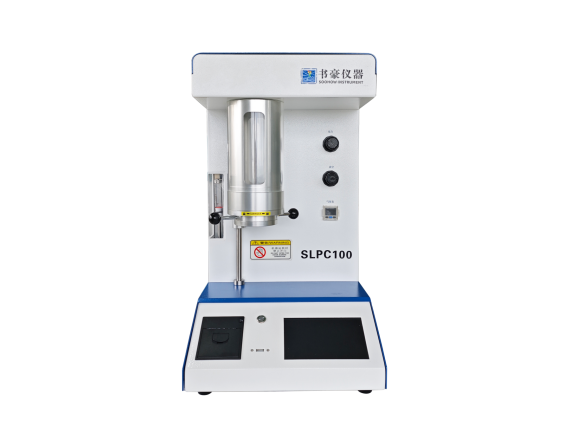

Penghitung Partikel Oli Desktop SLPC100

SLPC100 adalah penghitung partikel oli desktop yang menggunakan metode pengaburan cahaya. Dirancang ...

Oil Analysis

Oil Analysis

Viskometer Gerak Cepat Portabel VS600

VS600 Portable Rapid Motion Viscometer adalah instrumen lapangan berefisiensi tinggi yang dirancang ...

Oil Analysis

Oil Analysis

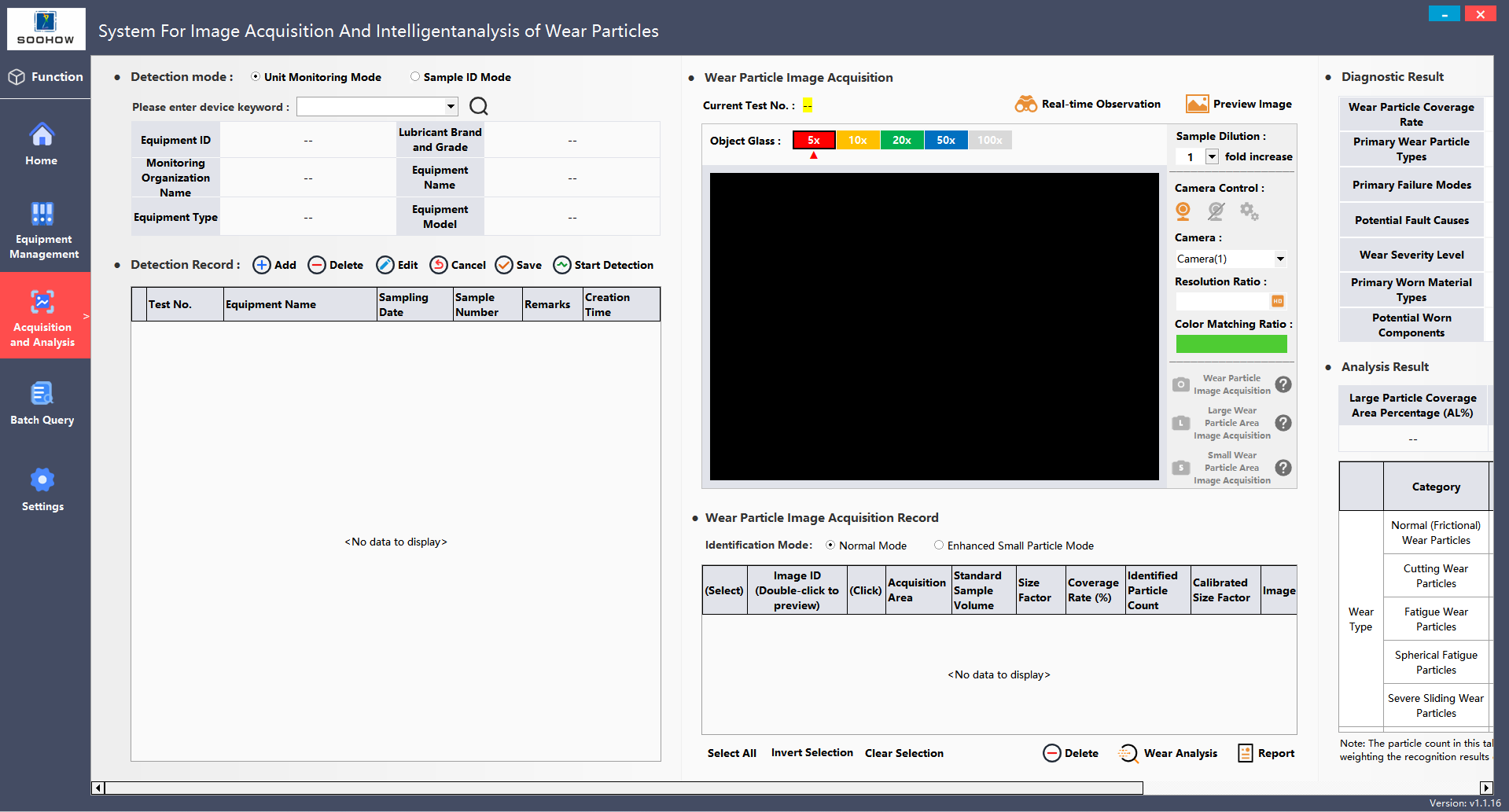

Sistem Akuisisi Gambar & Analisis Cerdas Partikel Keausan Berbasis AI

Sistem canggih ini adalah solusi mutakhir untuk Ferografi modern dan pemantauan kondisi oli. Dengan ...

Siap Menemukan Solusi yang Tepat?

Tim kami dapat membantu Anda memilih produk yang sempurna untuk Armada Peralatan Pertambangan aplikasi