Produits laitiers et boissons

Aperçu de l'Industrie

Caractéristiques Clés

Les défis courants incluent la sédimentation, le crémage et la détérioration microbienne. La stabilité dépend de la taille des particules, de la charge de surface, de la viscosité et des interactions entre les composants. Une mauvaise stabilité entraîne une perte de qualité, une durée de conservation réduite et une expérience sensorielle dégradée.

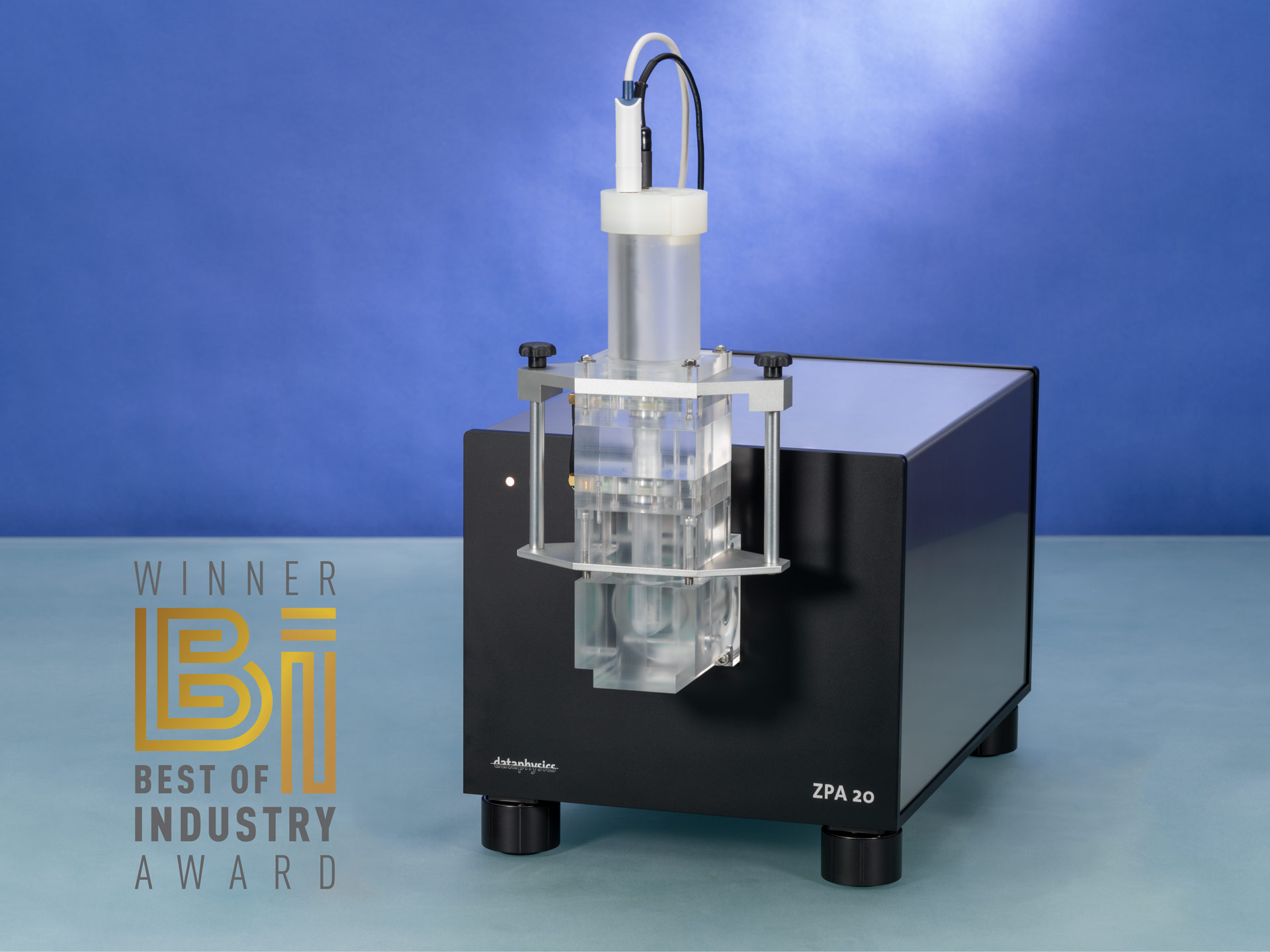

DataPhysics Instruments apporte des solutions pratiques. Le système MultiScan surveille la stabilité des boissons au fil du temps et détecte précocement les signes de sédimentation ou de crémage. Le ZPA 20 mesure le potentiel zêta, indicateur de la répulsion électrostatique entre particules : des valeurs élevées suggèrent une bonne stabilité, des valeurs faibles signalent un risque d’agrégation. Le tensiomètre DCAT mesure la tension interfaciale, aidant les formulateurs à comprendre comment les stabilisants et les tensioactifs maintiennent l’homogénéité.

En R&D, ces outils permettent d’optimiser la concentration en stabilisants, la taille des particules et la viscosité. En production, ils soutiennent l’assurance qualité en fournissant des mesures reproductibles et automatisées qui garantissent la cohérence d’un lot à l’autre. Les produits laitiers et les boissons ne sont pas de simples consommables : ce sont des systèmes conçus qui exigent un contrôle précis des propriétés colloïdales et interfaciales. DataPhysics Instruments permettent aux fabricants d’atteindre ce niveau de contrôle, favorisant l’innovation et la satisfaction des consommateurs.

Tests et Applications Typiques

- But : Suivre le comportement des boissons dans le temps.

- Application : Détecter la sédimentation ou le crémage.

- Bénéfice : Assurer une longue durée de conservation et une texture constante.

- Mesure du potentiel zêta (ZPA 20)

- But : Évaluer la charge de surface des particules.

- Application : Prédire la stabilité et prévenir l’agrégation.

- Bénéfice : Optimiser l’utilisation des stabilisants.

- Mesure de la tension interfaciale (DCAT)

- But : Évaluer l’efficacité des stabilisants.

- Application : Maintenir l’homogénéité.

- Bénéfice : Améliorer la texture en bouche et la consistance.

- Analyse dynamique de l’angle de contact (OCA, DCAT)

- But : Étudier le mouillage des particules dans le liquide.

- Application : Améliorer la dispersion.

- Bénéfice : Prévenir l’agglomération et la séparation.

Ressources de l'Industrie

Pas de Ressources Disponibles

Nous mettons à jour notre bibliothèque de ressources pour cette industrie. Revenez bientôt ou contactez-nous pour demander une documentation spécifique.

Demander une DocumentationProduits de Support

Contact Angle & Surface Tension

Contact Angle & Surface Tension

DCAT – Appareils de mesure d’angle de contact dynamique et tensiomètre

La série DCAT polyvalente combine des dispositifs de mesure d’angle de contact dynamique et des t...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

MS – Système MultiScan d’analyse de stabilité de dispersion

Le MultiScan MS 20 est un analyseur optique avancé conçu pour l’analyse automatique de la stab...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

SVT – Tensiomètre vidéo à goutte tournante

Le SVT 25 est un instrument optique spécialisé pour mesurer les tensions interfaciales ultra-fai...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

ZPA – Analyseur de potentiel zêta

Le ZPA 20 est un instrument compact et de haute précision qui mesure le potentiel zêta de surfac...

Prêt à Trouver la Bonne Solution?

Notre équipe peut vous aider à sélectionner les produits parfaits pour vos Produits laitiers et boissons applications