Polimer

Ikhtisar Industri

Fitur Utama

Surface properties play a pivotal role in determining how polymers interact with other materials. For instance, in packaging, the adhesion of inks and coatings to polymer films must be optimized for durability and print quality. In automotive and aerospace, polymer composites must exhibit strong bonding with structural components while resisting environmental degradation.

DataPhysics Instruments offers a suite of analytical tools tailored to these needs. The OCA (Optical Contact Angle) systems measure static and dynamic contact angles, surface free energy, and spreading behavior. These parameters help assess how well a polymer surface can be wetted or bonded. The DCAT (Dynamic Contact Angle Tensiometer) provides insights into surface tension and interfacial tension, crucial for understanding interactions between polymers and liquids. The PCA 200, a portable contact angle goniometer, enables on-site measurements, ideal for quality control in production environments.

Polymers often undergo surface treatments—such as plasma, corona, or chemical etching—to enhance adhesion or modify wettability. DataPhysics devices can quantify the effectiveness of these treatments by comparing contact angle and surface energy values before and after processing. This capability is vital for ensuring consistency and performance in treated polymer surfaces.

In research and development, these instruments support the formulation of new polymer blends, coatings, and composites. By providing detailed surface characterization, they enable scientists and engineers to tailor materials for specific applications, reduce trial-and-error, and accelerate innovation.

Moreover, the polymer industry benefits from the integration of DataPhysics tools into automated workflows and quality assurance protocols. With high-resolution imaging, precise dosing systems, and software-controlled analysis, these instruments deliver reproducible, high-throughput data essential for modern manufacturing and R&D.

Tes & Aplikasi Khas

1. Contact Angle Measurement (OCA, PCA 200)

Purpose: Evaluate wettability and surface cleanliness.

Application: Determine how well coatings, adhesives, or inks will spread or adhere to polymer surfaces.

Benefit: Optimize surface treatments and ensure consistent product performance.

2. Surface Free Energy (SFE) Analysis (OCA)

Purpose: Quantify the polar and dispersive components of surface energy.

Application: Predict adhesion behavior and compatibility with other materials.

Benefit: Select appropriate adhesives or coatings for specific polymer substrates.

3. Dynamic Contact Angle & Hysteresis (OCA, DCAT)

Purpose: Assess advancing and receding contact angles.

Application: Evaluate surface roughness, heterogeneity, and dynamic wetting behavior.

Benefit: Improve surface uniformity and functional coating performance.

4. Surface Tension & Interfacial Tension (DCAT)

Purpose: Measure the tension between polymer solutions and other liquids.

Application: Formulate emulsions, dispersions, or blends involving polymers.

Benefit: Enhance product stability and processing efficiency.

5. Wetting Envelope & Spreading Coefficient (OCA Software)

Purpose: Visualize the range of liquids that can wet a polymer surface.

Application: Select optimal solvents, inks, or adhesives.

Benefit: Reduce material waste and improve adhesion outcomes.

These tests provide a comprehensive understanding of polymer surface behavior, enabling manufacturers and researchers to make informed decisions in design, processing, and quality control. Whether developing new materials or optimizing existing ones, DataPhysics tools are indispensable for advancing polymer technology.

Sumber Daya Industri

Tidak Ada Sumber Daya Tersedia

Kami sedang memperbarui perpustakaan sumber daya kami untuk industri ini. Periksa kembali segera atau hubungi kami untuk meminta dokumentasi khusus.

Minta DokumentasiProduk Pendukung

Contact Angle & Surface Tension

Contact Angle & Surface Tension

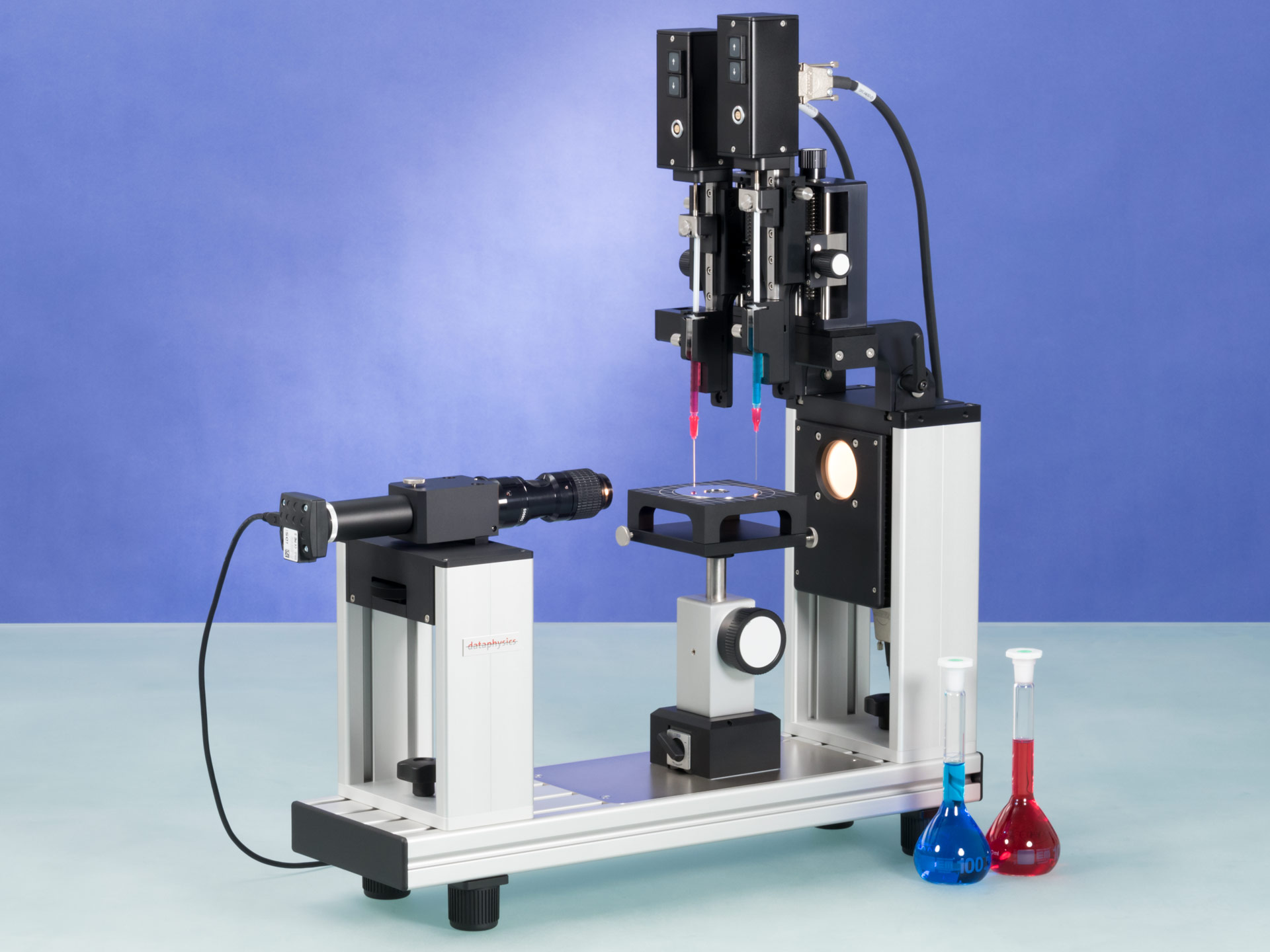

DCAT – Alat Ukur Sudut Kontak Dinamis dan Tensiometer

Seri DCAT menggabungkan perangkat pengukur sudut kontak dinamis dan tensiometer gaya untuk mengevalu...

Oil Analysis

Oil Analysis

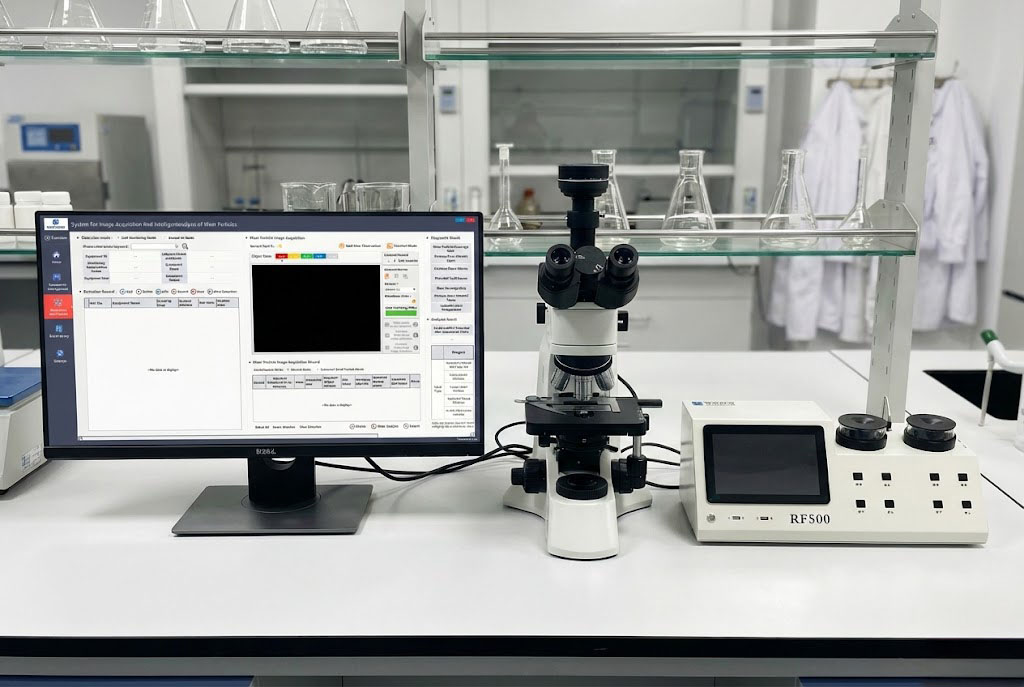

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

OCA – Sistem Pengukuran Sudut Kontak Optik dan Analisis Kontur

Seri OCA terdiri dari goniometer sudut kontak optik presisi tinggi yang menentukan sifat permukaan d...

Contact Angle & Surface Tension

Contact Angle & Surface Tension

PCA – Goniometer Sudut Kontak Portabel

PCA 200 adalah goniometer sudut kontak genggam yang ringkas, dirancang untuk pengukuran energi permu...

Siap Menemukan Solusi yang Tepat?

Tim kami dapat membantu Anda memilih produk yang sempurna untuk Polimer aplikasi