Oil & Gas Exploration

نظرة عامة على الصناعة

الميزات الرئيسية

Challenges

Oil exploration is often done in remote locations, making the use of off-site oil analysis laboratories impractical. Off shore oil rigs are a perfect example. By the time an oil sample is taken, sent ashore, analyzed the results returned to the rig, weeks may have passed. In that time a critical piece of equipment could fail.

Bringing oil analysis on-site greatly reduces cost of analysis and improves predictive maintenance.

The same logic applies when testing produced water. On-site analysis provides actionable results quickly, allowing operators to know if their results are meeting regulatory requirements.

الاختبارات والتطبيقات النموذجية

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Total Base Number (TBN) - TBN measures the amount of active additive left in a sample of oil. The TBN is useful for people who want to extend their oil usage far beyond the normal range. The TBN of a used oil can aid the user in determining how much reserve additive the oil has left to neutralize acids. The lower the TBN reading, the less active additive the oil has left.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Contamination

Fuel Dilution - Fuel dilution in oil is a condition caused by excess, unburned fuel mixing with engine oil in an engine crankcase. Hydrocarbon-based fuel, usually with a lower vapor pressure than the lubricant, has a thinning effect, lowering the oil viscosity. Oil film strength is reduced, increasing the cylinder liner and bearing wear.

Soot - Soot is a product of combustion and has always been found in engine oils. Soot can use up an oil's additives and deposit on vital engine surfaces.

Glycol - Glycol is found in engine coolant. If glycol is found in engine oil it typically indicates there is a leak in the engine that can cause catastrophic damage to the cylinder or cylinder wall.

Water - Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

Produced Water

Complies with ASTM D7066, EPA 413.2 & 418.1

Compares with EPA 1664

Detect levels as low as 0.1 mg/L

Unlike UV, measures aromatic and aliphatic hydrocarbons

Two InfraCal Analyzers suitable for this application

موارد الصناعة

لا تتوفر موارد

نقوم حالياً بتحديث مكتبة الموارد لهذه الصناعة. عد قريباً أو اتصل بنا لطلب وثائق محددة.

طلب الوثائقالمنتجات الداعمة

Oil Analysis

Oil Analysis

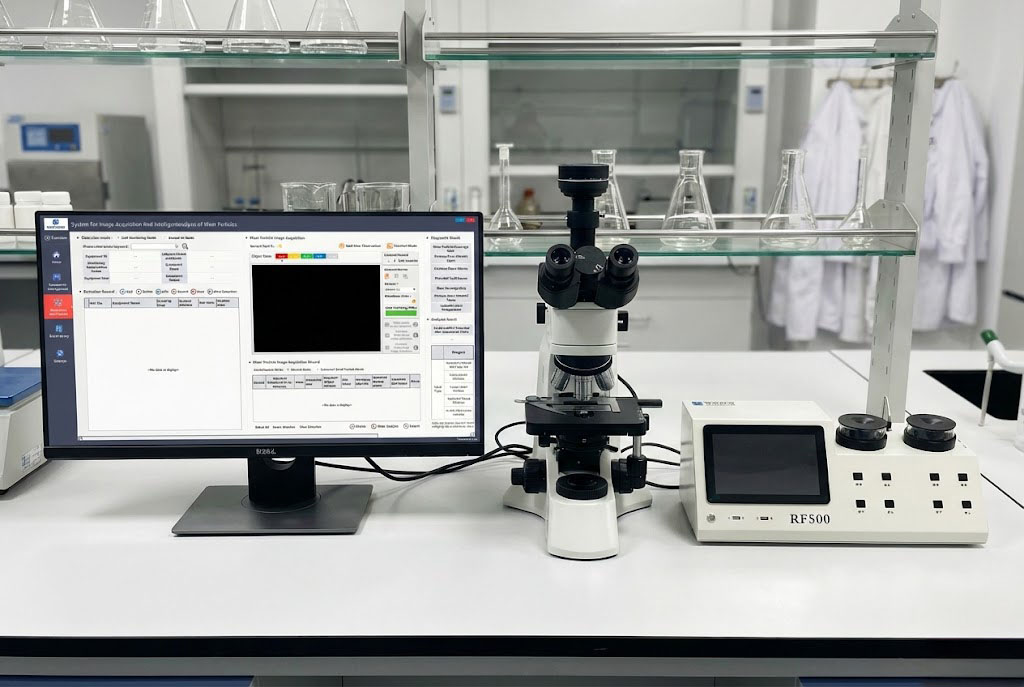

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

ميني فيسك 3000

MiniVisc 3000 هو مقياس لزوجة حركية محمول ثوري يوفر قياسات لزو...

Oil Analysis

Oil Analysis

باي رابتور المحمول

محلل حجم وشكل الجسيمات المحمول Raptor هو أول نظام محمول حق...

Oil Analysis

Oil Analysis

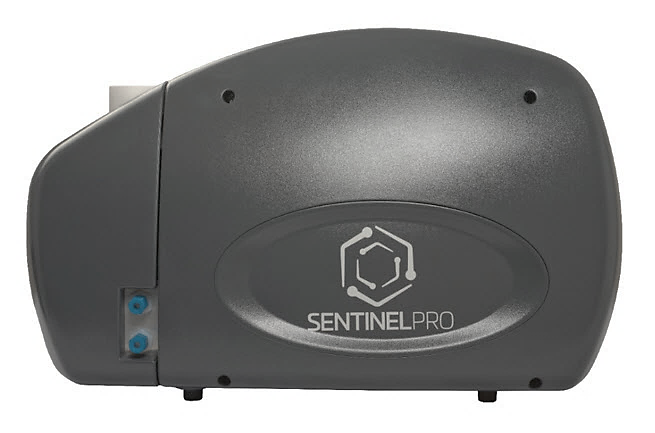

باي سنتينل برو

SentinelPro هو محلل صور ديناميكي عالي الأداء مصمم للتطبيقات ...

Oil Analysis

Oil Analysis

اللزوجة الحركية المحمولة VS800

مقياس اللزوجة الحركية المحمول VS800 هو أداة دقيقة متعددة ...

Oil Analysis

Oil Analysis

روتر أويل R4 (مغير عينات أوتوماتيكي)

R4 RotrOil هو نسخة متقدمة أوتوماتيكية بالكامل من مطياف العن...

Oil Analysis

Oil Analysis

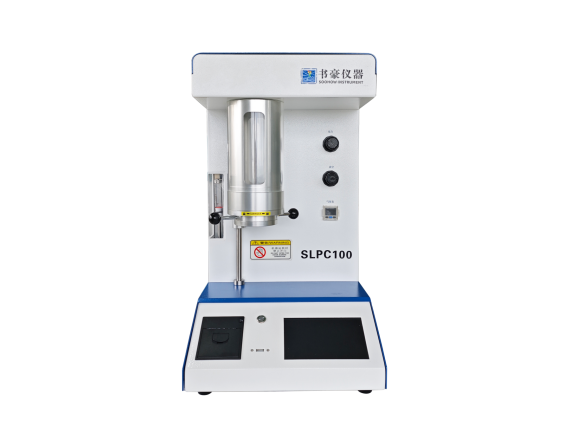

عداد جسيمات الزيت المكتبي SLPC100

جهاز SLPC100 هو عداد جسيمات زيت مكتبي يستخدم طريقة العد ال�...

Oil Analysis

Oil Analysis

سلسلة سبكترو أويل 100

سلسلة SpectrOil 100 هي محلل عناصر عالي الدقة يعتمد على تقنية �...

Oil Analysis

Oil Analysis

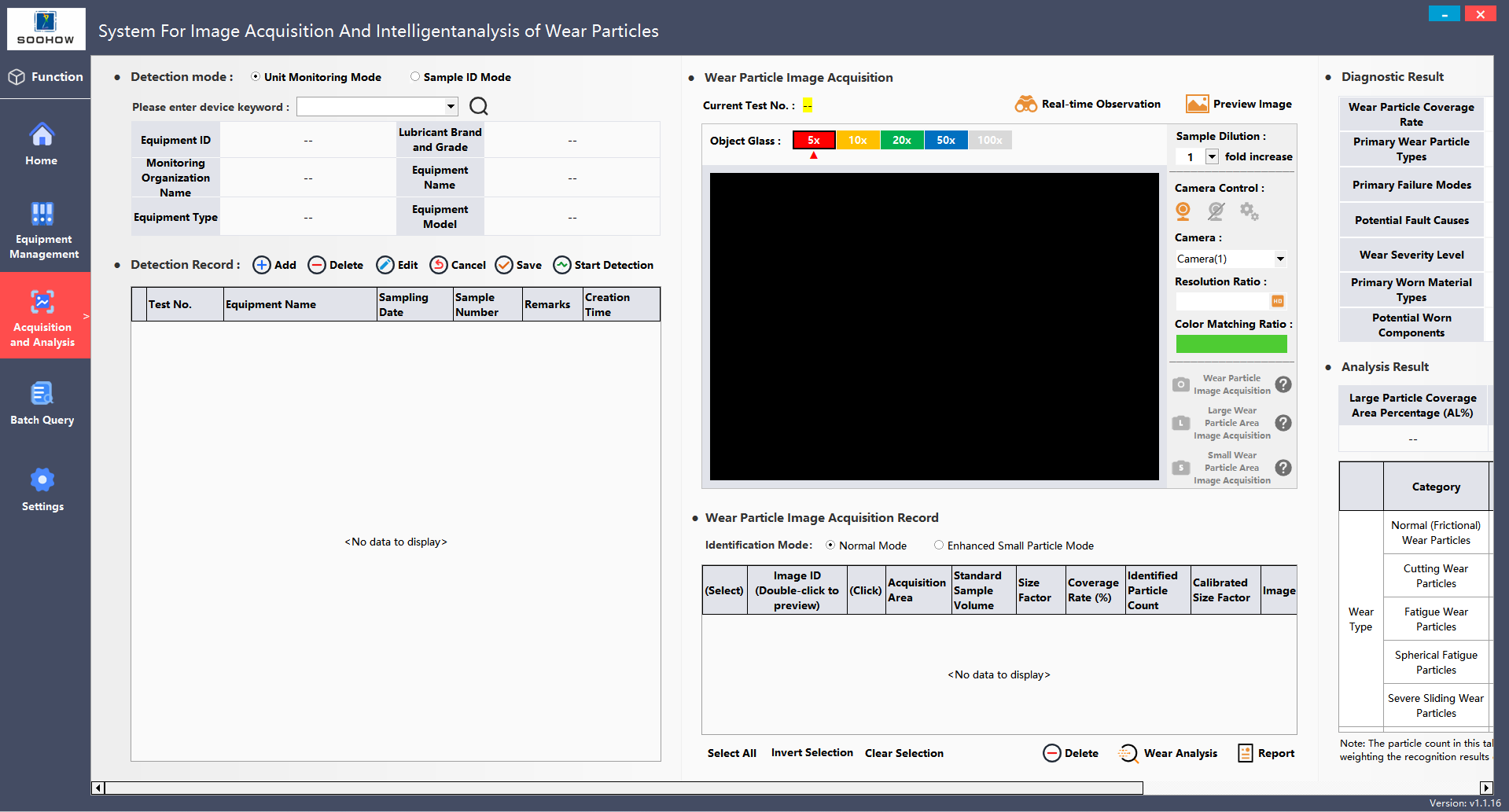

نظام الحصول على صور جزيئات التآكل والتحليل الذكي المدعوم بالذكاء الاصطناعي

This advanced system is a cutting-edge solution for modern Ferrography and oil condition monitoring....

مستعد للعثور على الحل المناسب؟

يمكن لفريقنا مساعدتك في اختيار المنتجات المثالية لتطبيقات Oil & Gas Exploration التطبيقات