Pulp & Paper

Muhtasari wa Sekta

Vipengele Muhimu

For pulp and paper companies the drying roll is at the heart of production and downtime can cost many thousands of dollars an hour for larger facilities. Consequently the oil-wetted machinery, in a paper rolling machine, consisting primarily of gears and bearings is of critical importance.

Challenges

The heavy loads, high speeds and dirty, wet conditions make pulp and paper production a tough environment for any machine. Lubrication oil provides a thin layer of protection between moving metal parts. This layer is often on a few microns thick, so maintaining oil cleanliness is paramount. Water, dirt, sawdust and metal particles can interfere with that microlayer of lubrication oil and damage or destroy your valuable equipment.

Consistent and frequent oil analysis is the best defense against failures and costly downtime. Not only can oil analysis prevent failures, it can also let you know that it's safe to extend the lifetime of your oil, saving considerable money on new oil, labor, filters and disposal of lubrication oil.

Majaribio na Matumizi ya Kawaida

Particle count - a high particle count or a rapid increase in particles can foreshadow an imminent failure.

Particle composition - it is often important to understand the elemental composition of particles in order to find out where they came from. Optical Emission Spectroscopy gives the user elemental information for up to 32 elements, from Li to Ce (varies with application).

Particle type - The size, shape and opacity of particles is used to determine if they are from cutting wear, sliding wear, fatigue wear, nonmetallic or fibers. This allows operators to determine the type of wear debris, wear mode and potential source from internal machinery components.

Ferrous wear - Ferrous wear measurement is a critical requirement for monitoring machine condition. The high sensitivity magnetometer measures and reports ferrous content in ppm/ml, and provides ferrous particle count and size distribution for large ferrous particles.

Chemistry

Total Acid Number (TAN) - TAN is measured to determine the corrosive potential of lubrication oils. If the TAN gets too high the oil can induce corrosion of machine parts and should be changed.

Viscosity - The main function of lubrication oil is to create and maintain a lubrication film between two moving metal surfaces. Insuring the viscosity is within recommended ranges is one of the most important tests one can run on lube oil.

Contamination

Water- Water contamination in industrial oils can cause severe issues with machinery components. The presence of water can alter the viscosity of a lubricant as well as cause chemical changes resulting in additive depletion and the formation of acids, sludge, and varnish.

Rasilimali za Sekta

Hakuna Rasilimali

Tunasasisha maktaba ya rasilimali kwa sekta hii. Rudi baadaye au wasiliana nasi kupata nyaraka maalum.

Omba NyarakaBidhaa Zinazounga Mkono

Oil Analysis

Oil Analysis

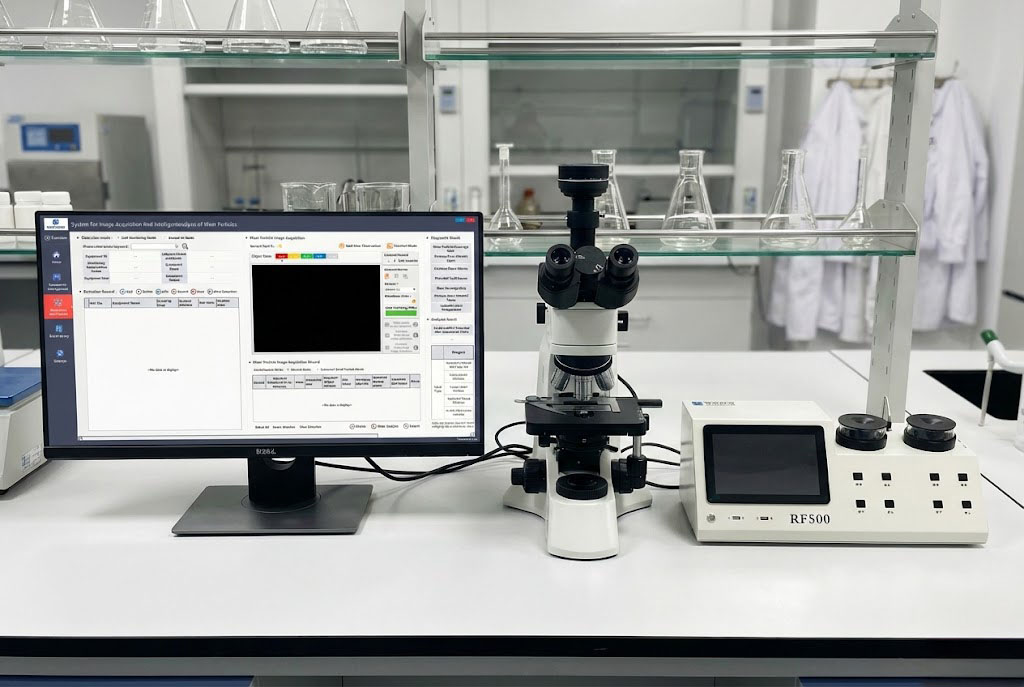

Intelligent Ferrography Lab (IFL-500 Series)

The Intelligent Ferrography Lab (IFL-500) is the world’s most advanced workstation for high-precis...

Oil Analysis

Oil Analysis

MiniVisc 3000

MiniVisc 3000 ni viscometer ya kinematic ya kubebeka ya kuvunja mipaka inayotoa vipimo vya viscosity...

Oil Analysis

Oil Analysis

Pi Raptor Inayobebeka

Raptor Portable Dry Powder Particle Size & Shape Analyzer ni mfumo wa kwanza wa kubebeka kabisa unao...

Oil Analysis

Oil Analysis

Viscometer ya Kinematic ya Kubebeka VS800

Viscometer ya kinematic ya kubebeka VS800 ni chombo cha kupima viscosity kwa usahihi, chenye matumiz...

Oil Analysis

Oil Analysis

Kichukua sampuli cha shinikizo chanya na hasi PC‑VES

PC‑VES ni kifaa cha kubebeka cha kuchukua sampuli ya mafuta chenye shinikizo chanya/has negative k...

Oil Analysis

Oil Analysis

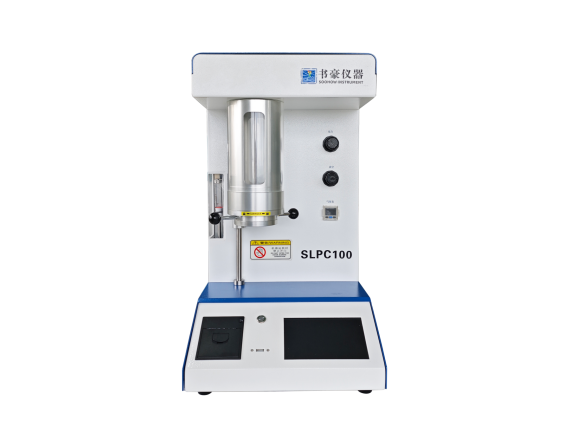

Kihesabu chembe za mafuta cha mezani SLPC100

SLPC100 ni kihesabu chembe za mafuta cha mezani kinachotumia mbinu ya kuhesabu inayotambulika kimata...

Uko Tayari Kupata Suluhisho Sahihi?

Timu yetu inaweza kukusaidia kuchagua bidhaa bora kwa matumizi yako Pulp & Paper matumizi