Particle analysis is a critical aspect of quality control in various industries, and the latest generation of the traditional Particle Insight instrument represents a significant leap forward in this field. This class-leading dynamic image analyzer is designed to go beyond particle size measurement, placing a strong emphasis on particle shape—a crucial factor in predicting raw material quality and maintaining precise process control.

The Particle Insight instrument is an ideal solution for applications where understanding particle shape is essential for ensuring product quality. This advanced analyzer offers a comprehensive assessment that considers not only the size of particles but also their morphology, providing critical insights into physical shape properties.

.

.

ـــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ

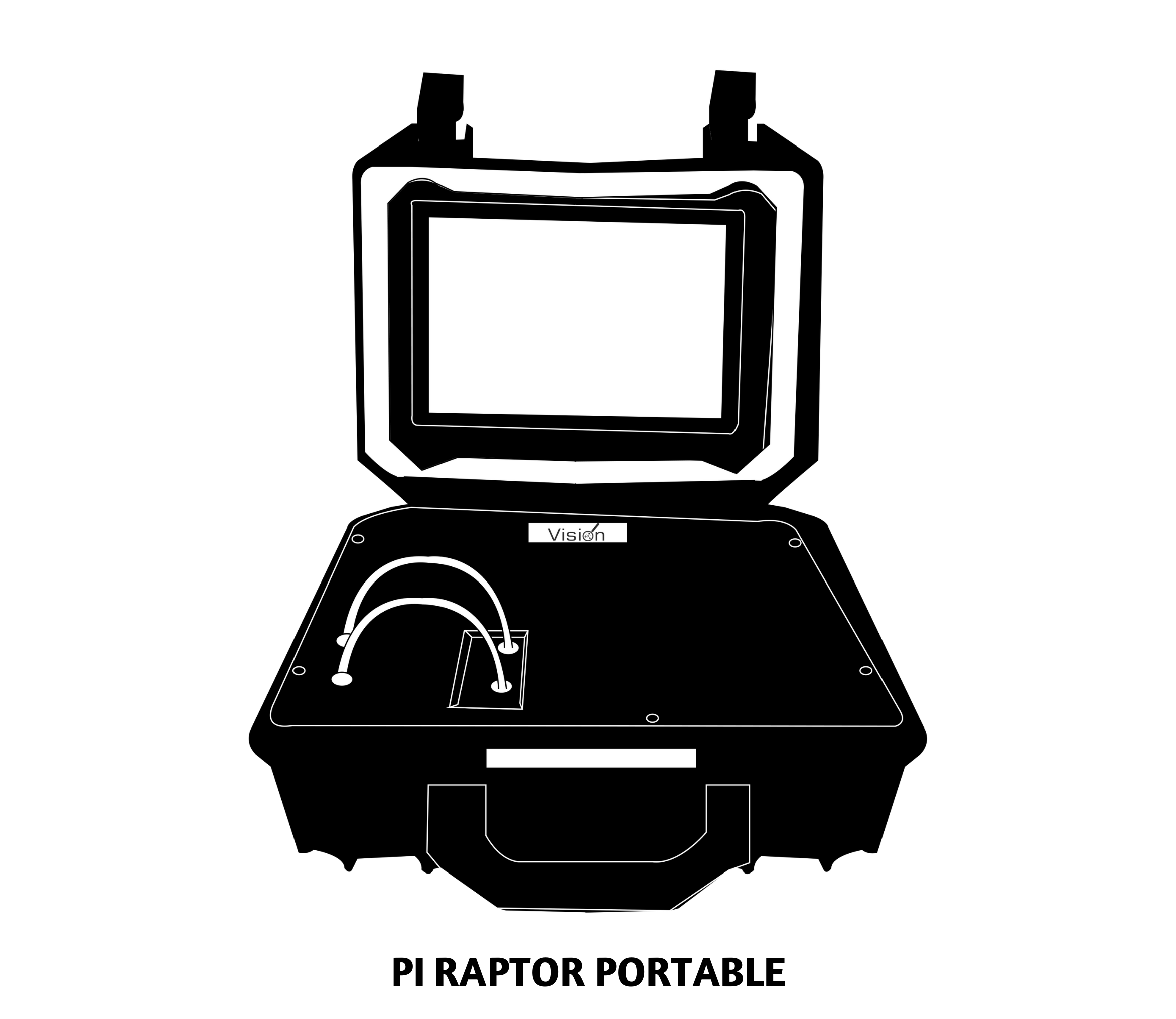

Pi Raptor Portable

Introduction

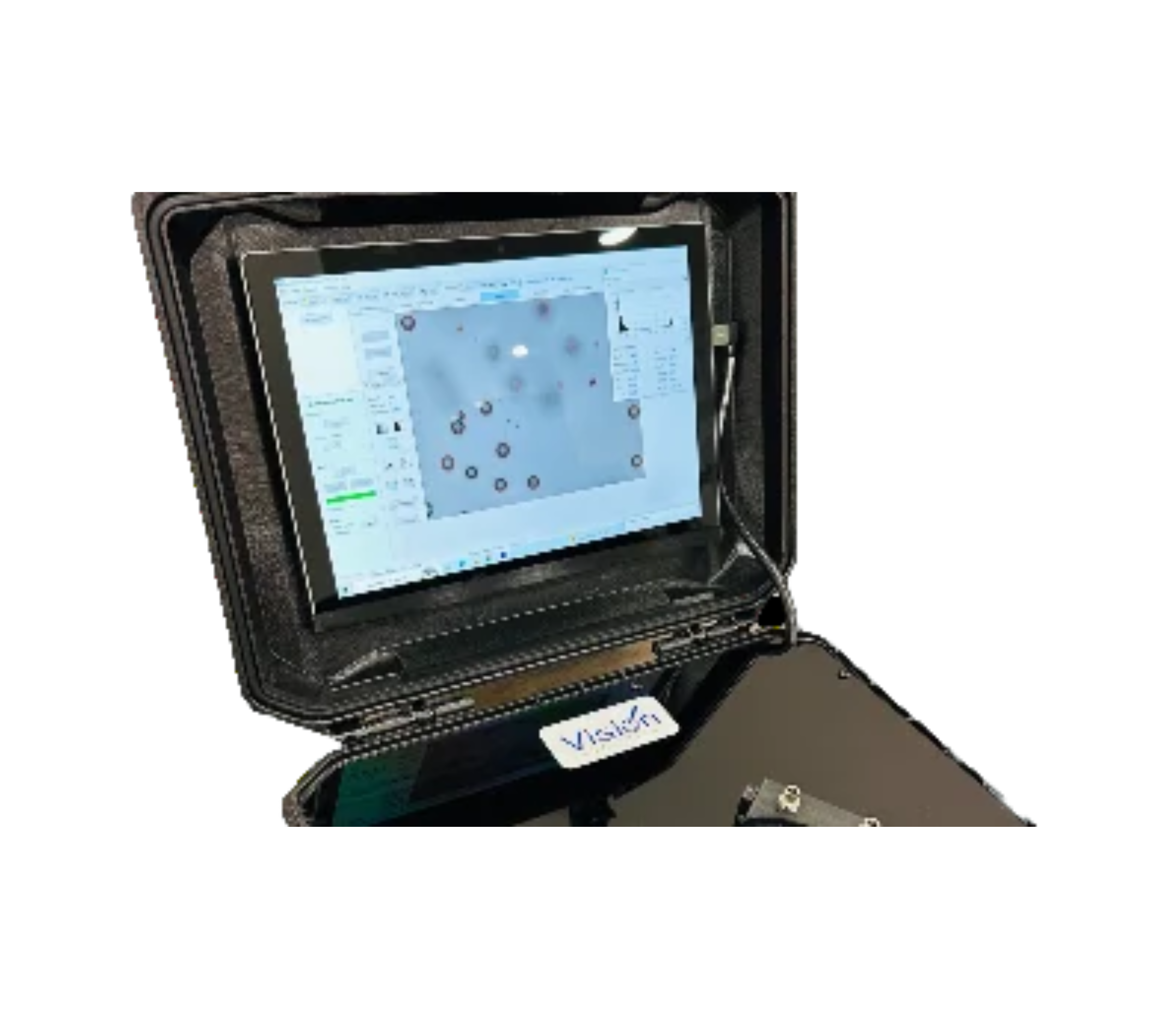

The Pi Raptor Portable, is a full featured particle size and shape analyzer enclosed in a ruggedized case for carry-on capability that enables taking a high-resolution particle analyzer anywhere. Having a portable system allows for at-site analysis with remote capabilities. The instrument uses Dynamic Image Analysis as a direct measurement technique, which has become more and more common as a Quality Control tool for raw materials in numerous industries. The new “Raptor” architecture offers a large array of improvements in image quality as well as functionality.

The Pi Raptor Portable is designed to operate as a fully functioning Particle Size and Shape Analyzer. It can be used at-lab where high quality data and ease-of-use is a requirement and it can also be closed and taken for remote use. The new sample handing capabilities also enable the system to operate for on-line applications.

Pi Portable main sections

- Microsoft Surface Pro computer with High-resolution touchscreen interface.

- Pi Raptor Portable modular hardware design features.

- New key software features.

ـــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ

Pi Raptor Portable

Introduction

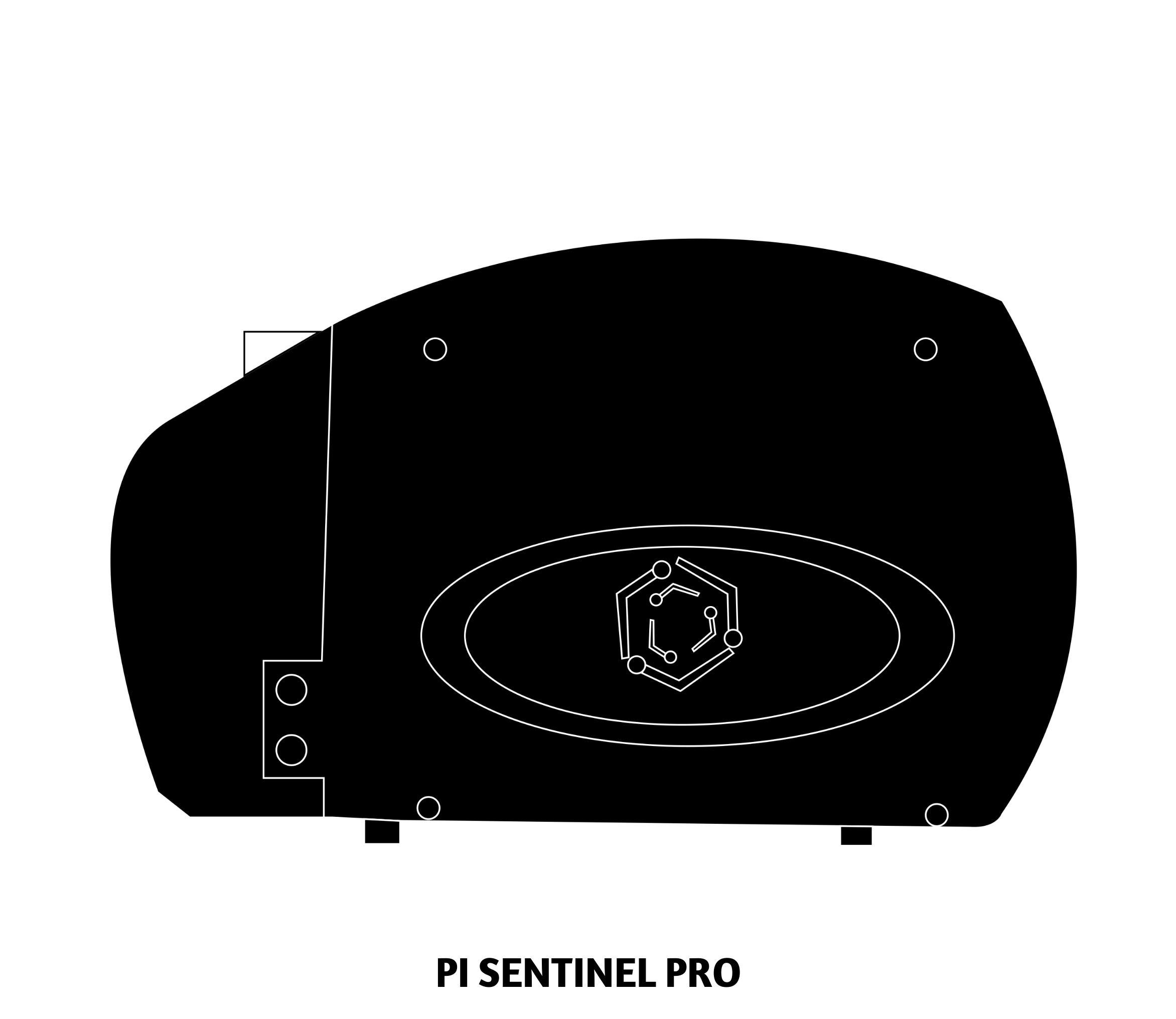

The Pi Sentinel PRO, new generation of the traditional Particle Insight instrument, is a class-leading dynamic image analyzer that is ideal for applications where particle shape, not just the particle size, may be critical information for predicting raw material quality and to maintain a high level of process control.

Particle morphology provides important information regarding the physical shape properties of your sample. It has been shown that shape can affect flowability, dispersion, packing density, segregation, aggregate formation, and microstructure character.

The fully automated Pi Sentinel PRO, now controlled by an All-in-One computer, is a well-suited research grade instrument or for use in a production process where speed, accuracy, and ease of use with its Pass/Fail shape control limits feature can be utilized.

Benefits of the Pi Sentinel PRO

- Higher speed data transfer rate, up to 127 frames per second rated digital camera with up to 5 MPs resolution, captures live images of thousands of particles.

- Over 30 shape parameters are recorded, including circularity, ellipticity, opacity, mean diameter, smoothness, aspect ratio, fiber length and many more..

- All analyzed particles have thumbnail images saved for post-run viewing and shape analysis, both in grey scale and binary views.

- Ability to compare different analyses via histogram overlays for all analyzed shape parameters.

- Scatter plot correlates two shape measurements and can be utilized as a process quality control criterion as an at-line application within unit operations.

- Unique and powerful software permits the use to simplify data processing to a pass/fail reporting or choose to extend data analysis to a full suite of post processing image and shape analysis reports.

ـــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــــ