Highlights

Oil analysis provides early indications of equipment wear and identifies the root causes of corrosion. On-site oil analysis eliminates the wait associated with sending samples off-site and enables immediate decision making.

With three simple test, the MiniLab 53 delivers comprehensive on-site oil analysis, providing immediate actionable results, saving time and reducing costs. Highlights of this system include:

- One product, delivering lab-quality analysis outside of the lab

- Simplified workflow for the non-expert user, no chemist required

- Simplified operation, data reporting and report interpretation via the TruVu 360 Diagnostic Sets with recommended actions.

Trivector™ – oil and machine health simplified

The TriVector™ is a simple representation of the integrity of the lubrication system and the health of the machine itself. The Trivector indicates the degree of health in each vector. In order to understand the Trivector condition, one must measure the key physical and chemical parameters of the oil.

The following questions can be answered:

The MiniLab 53 combines three simple tests that take less than 10 minutes to complete

(Click on any three tests images below to watch how-to videos)

TruVu 360 Enterprise Fluid Intelligence

The Minilab 53 uses the TruVu 360 Enterprise Fluid Intelligence software which includes an Asset Management database and a reference oil database which can be expanded by the end user.

It provides a standard sample trend reports and Diagnostic Sets with alarm limit templates, diagnostics, and recommended actions. It can support automatic email distribution of reports.

Color-coded Trivector reports provide a clear snapshot of machinery health by identifying parameters that are outside normal limits.

Target Industries

The MiniLab 53 is ideal for a wide range of industries such as:

Typical limits for machinery

The most common oil analysis tests and typical alarm limits for several component types are shown below. Component manufacturers establish alarm limits for their equipment for specified parameters.

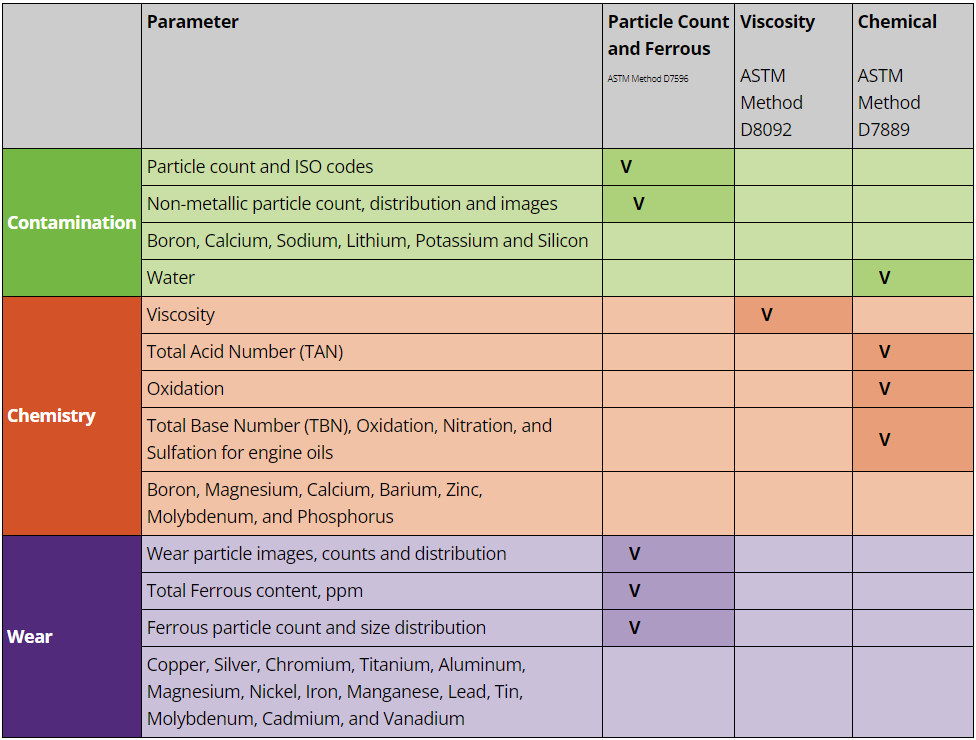

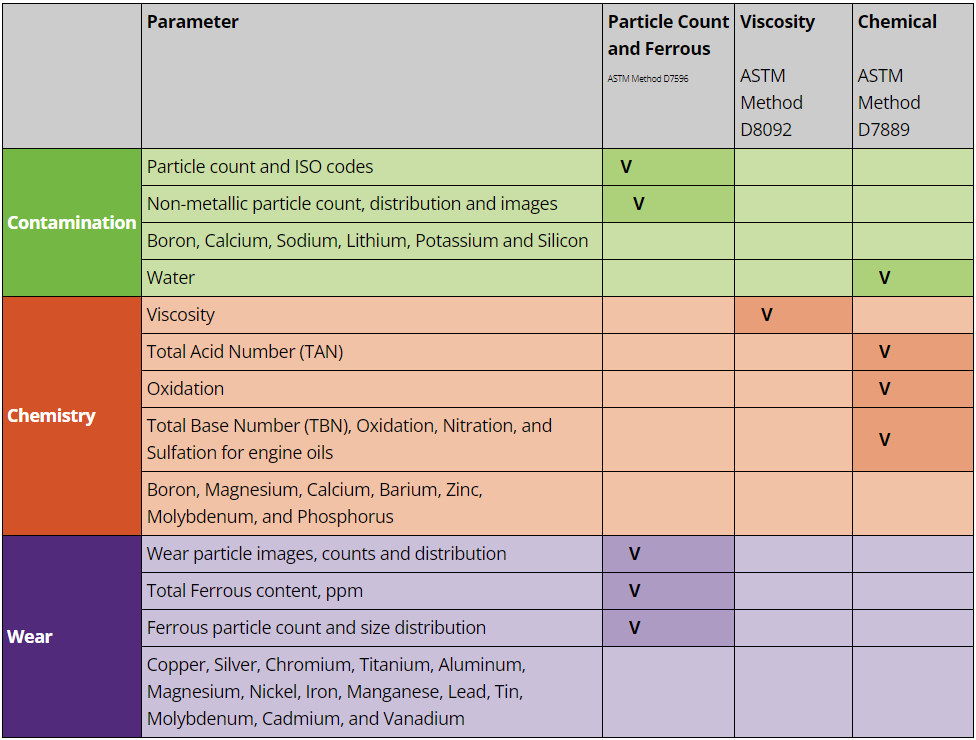

Tests: 3 simple tests within minutes to comprehensive oil analysis.

Methodology: ASTM D7596, ASTM D8092, ASTM 7889

Calibration: Factory calibrated, field calibration not required. Validation and standardization fluids supplied.

OPERATIONAL SPECIFICATIONS

Environmental Requirements: 5-40°C ambient temperature, 10-80% RH non-condensing, 2000 m maximum altitude

Sample Volume: 30-50 ml, varies with viscosity

Solvents: LaserNet Flush, lamp oil or odorless kerosene.

Application

Oil analysis provides early indications of equipment wear and identifies the root causes of corrosion. On-site oil analysis eliminates the wait associated with sending samples off-site and enables immediate decision making.

Features

- Comprehensive on-site oil analysis with three simple tests

- One product, delivering lab-quality analysis outside of the lab

- Simplified workflow for the non-expert user, no chemist required

- Simplified operation, data reporting and report interpretation via the TruVu 360 Diagnostic Sets with recommended actions

- Trivector™ - oil and machine health simplified

- TruVu 360 Enterprise Fluid Intelligence software for data management and analysis

- Standard sample trend reports and Diagnostic Sets with alarm limit templates, diagnostics, and recommended actions

- Automatic email distribution of reports

- Color-coded Trivector reports provide a clear snapshot of machinery health by identifying parameters that are outside normal limits

Trivector™

The TriVector™ is a simple representation of the integrity of the lubrication system and the health of the machine itself. The Trivector indicates the degree of health in each vector. In order to understand the Trivector condition, one must measure the key physical and chemical parameters of the oil.

Target Industries

Sample Preparation Equipment

Sample preparation equipment such as the Homogenizer, Ultrasonic Degasser, Electrode Sharpener and Consumables for 100 samples are included with each MiniLab 153 instrument.

Sample Preparation – 3 Simple Steps

- Sharpen electrode

- Homogenize the sample for better water measurement

- Ultrasonically degas the sample for particle analysis

Spectro Scientific consumables ensure high accuracy and repeatability

Homogenizer (on stand)

Homogenizer (on stand)

Ultrasonic Degasser

Ultrasonic Degasser

Consumables

Consumables

Homogenizer (on stand)

Homogenizer (on stand)  Ultrasonic Degasser

Ultrasonic Degasser Consumables

Consumables